Non-crystallization treatment method on alloy surface using power ultrasound

An amorphization and alloying technology, applied in the field of alloy surface treatment, can solve the problems of high heating temperature, affecting the ability of forming amorphous alloys, burning of alloy elements, etc., achieving simple treatment process, good surface roughness consistency, reducing The effect of workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

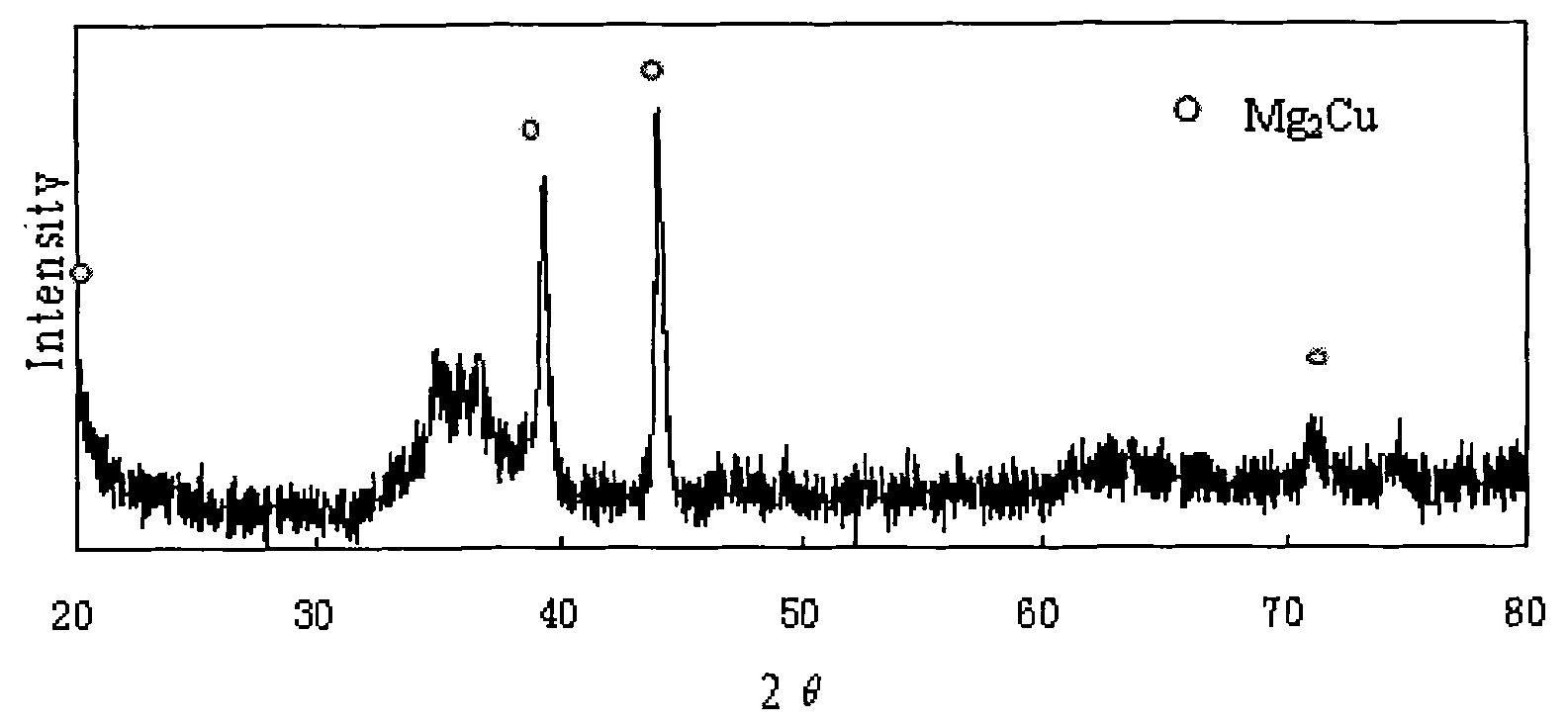

[0024] In the engine oil, the cavitation effect of 1.5KW power ultrasonic in the liquid medium is used to generate local high temperature and high pressure, and the surface of the alloy with certain amorphous forming ability is treated to form an amorphous layer on the surface of the alloy. Mg to be processed 65 Cu 25 Y 10 The alloy has a high amorphous forming ability, and the critical cooling rate is about 10 -2 K / s. The distance between the ultrasonic horn and the surface to be treated is 2mm, the time of ultrasonic action is 70min, the flow rate of engine oil is 200mL / min, Mg 65 Cu 25 Y 10 The average speed of reciprocating motion of the alloy sample is 100mm / s. After treatment, a well-distributed amorphous film layer was obtained on the surface of the alloy. The scanning electron microscope photos of the surface are as follows figure 1 As shown, the X-ray diffraction spectrum is shown as figure 2 .

Embodiment 2

[0026] In deionized water, the cavitation effect of 1.2KW ultrasonic power in deionized water will generate local high temperature and high pressure, which will affect Mg with certain amorphous forming ability. 65 Cu 25 Y 10 alloy surface treatment. Mg to be processed 65 Cu 25 Y 10 The alloy has a high amorphous forming ability, and the critical cooling rate is about 10 -2 K / s. The distance between the ultrasonic horn and the surface to be treated is 1mm, the time of ultrasonic action is 40min, the flow rate of deionized water is 150mL / min, Mg 65 Cu 25 Y 10 The average speed of reciprocating motion of the alloy sample is 100mm / s. After treatment, a well-distributed amorphous film layer was obtained on the surface of the alloy.

Embodiment 3

[0028] In deionized water, using 1.2KW power ultrasonic in deionized water, the rate of ultrasonic cavitation in deionized water will generate local high temperature and high pressure. 74 Al 4 Ga 2 P 12 B 4 Si 4 The surface of the alloy is treated to form an amorphous layer on the surface of the alloy. The alloy to be treated has a high amorphous-forming ability, and the critical cooling rate is about 10 -3 K / s. The distance between the ultrasonic horn and the surface to be treated is 2mm, the time of ultrasonic action is 100min, the flow rate of deionized water is 150mL / min, Mg 65 Cu 25 Y 10 The average speed of reciprocating motion of the alloy sample is 100mm / s. After treatment, a well-distributed amorphous film layer was obtained on the surface of the alloy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com