Method for preparing vertical structure LED using whole optical film system

A light-emitting diode, vertical structure technology, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of low light extraction efficiency, poor heat dissipation capacity, uneven current distribution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

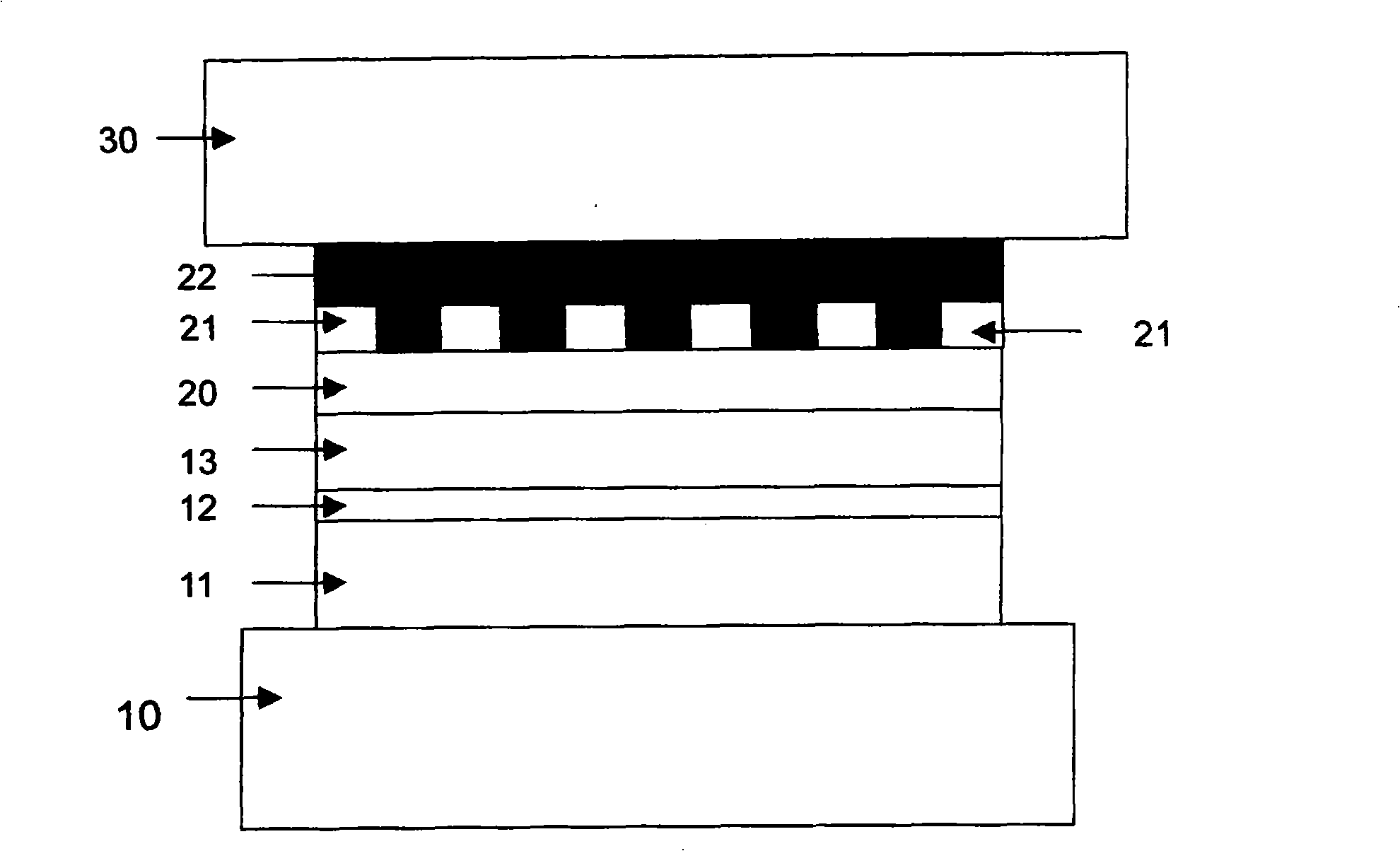

[0029] see Figure 1-Figure 4 As shown, a method for manufacturing a vertical structure light-emitting diode using an all-optical film system in the present invention comprises the following steps:

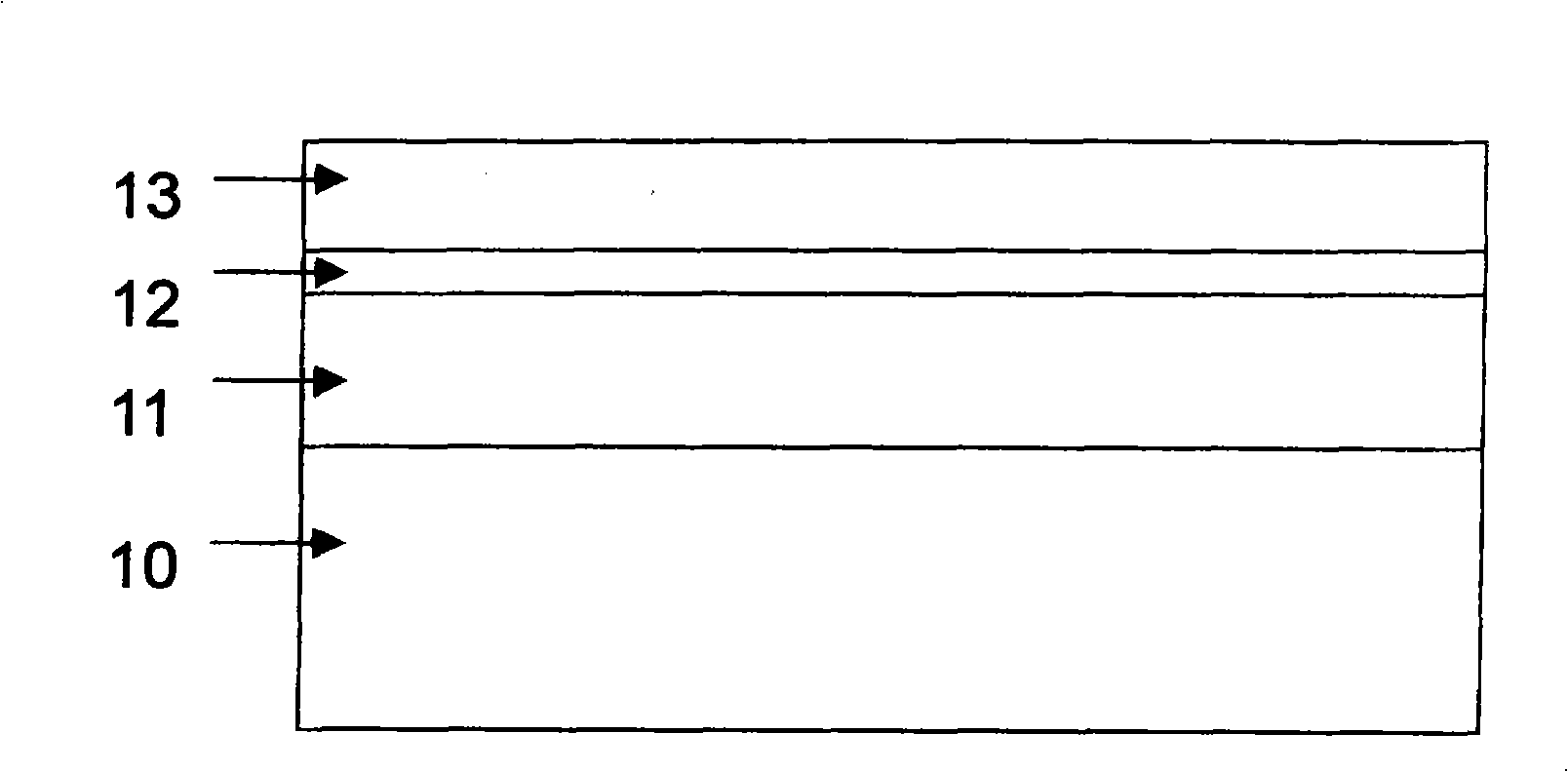

[0030] Step 1: Epitaxially grow GaN N-type contact layer 11, multi-quantum well active region 12 and GaN P-type contact layer 13 sequentially on substrate 10 by metal chemical organic vapor deposition method, the substrate 10 is sapphire Substrate;

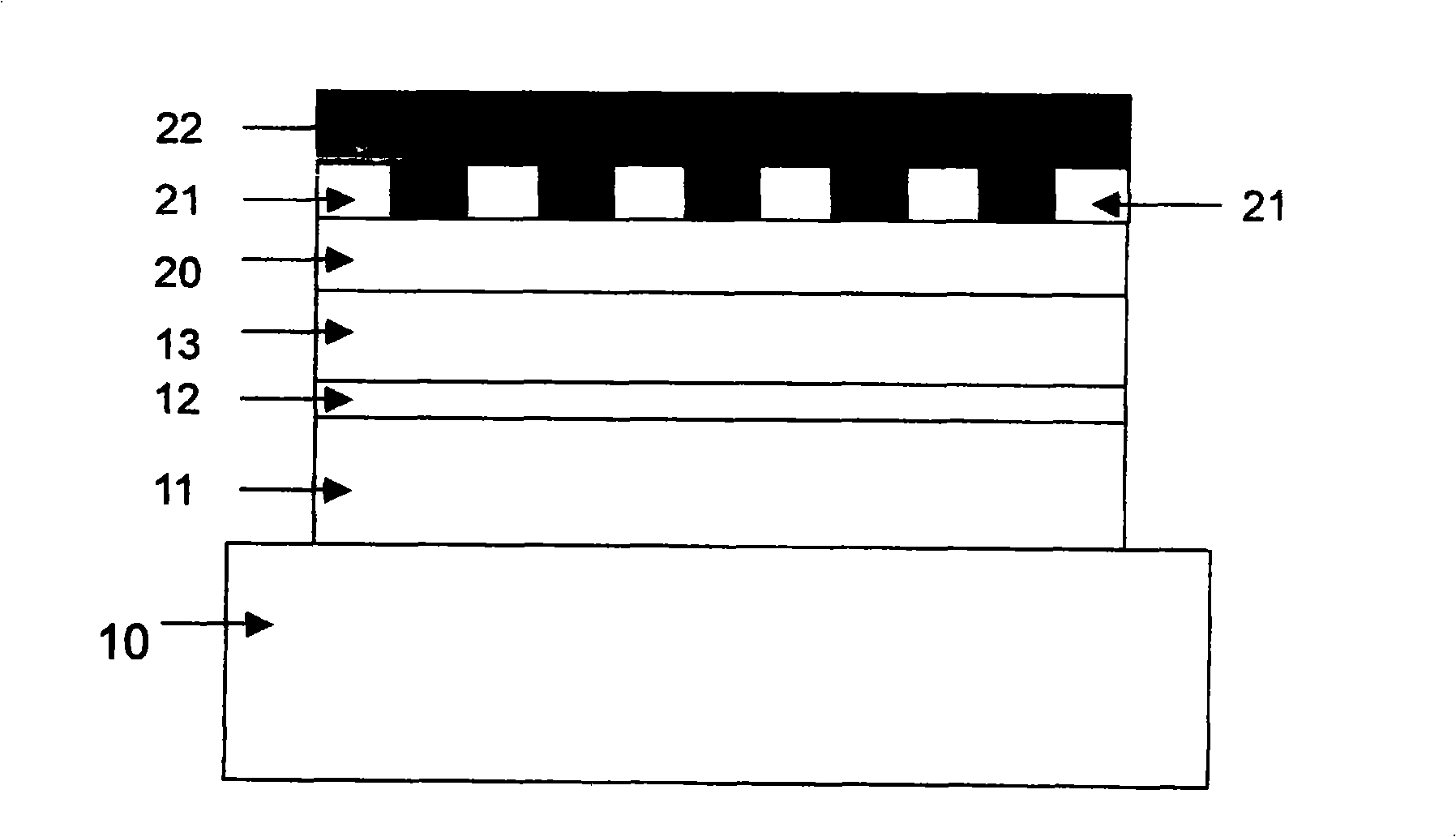

[0031] Step 2: Use inductively coupled plasma, electron cyclotron resonance, and reactive ion etching dry etching techniques for device isolation;

[0032] Step 3: Fabricate an ITO optical film 20 on the GaN P-type contact layer 13 by electron beam evaporation technology;

[0033] Step 4: Make a layer of optical high-reflection film 21 on the ITO optical film 20 by using ion beam sputtering technology. The high-reflection film adopts a mesh structure, that is, part of the ITO optical film 20 is covered by the optical high-reflection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com