Magnetic ferrocobalt ferrite prepared by hard formwork method and preparation method thereof

A hard template method and ferrite technology, which is applied in the field of new cobalt iron ferrite and its preparation, achieves the effect of low equipment requirements, high safety, and good ultraviolet light degradation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A. 3.9 grams of Co(NO 3 ) 2 ·6H 2 O, 4.6 g FeSO 4 ·7H 2 O and 2.6 g Fe 2 (SO 4 ) 3 Put into 50.0 ml of high-quality wood pulp with a concentration of 1.0% and stir until the solid mixture is fully dissolved.

[0035] B. Separately prepare 1.5M NaOH and 1.0M NaOH with deoxygenated deionized water 2 CO 3 50.0 ml of the mixed alkali solution, and under nitrogen protection and vigorous stirring, slowly add the alkali solution dropwise to the above salt solution until the pH ≈ 10.5, then continue to stir for 6.0 hours, stand at room temperature for 16.0 hours to crystallize, and filter , washed three times with deionized water and absolute ethanol, respectively. The solid matter is dried in vacuum to obtain the cobalt-iron-iron hydrotalcite / paper fiber adsorption assembly.

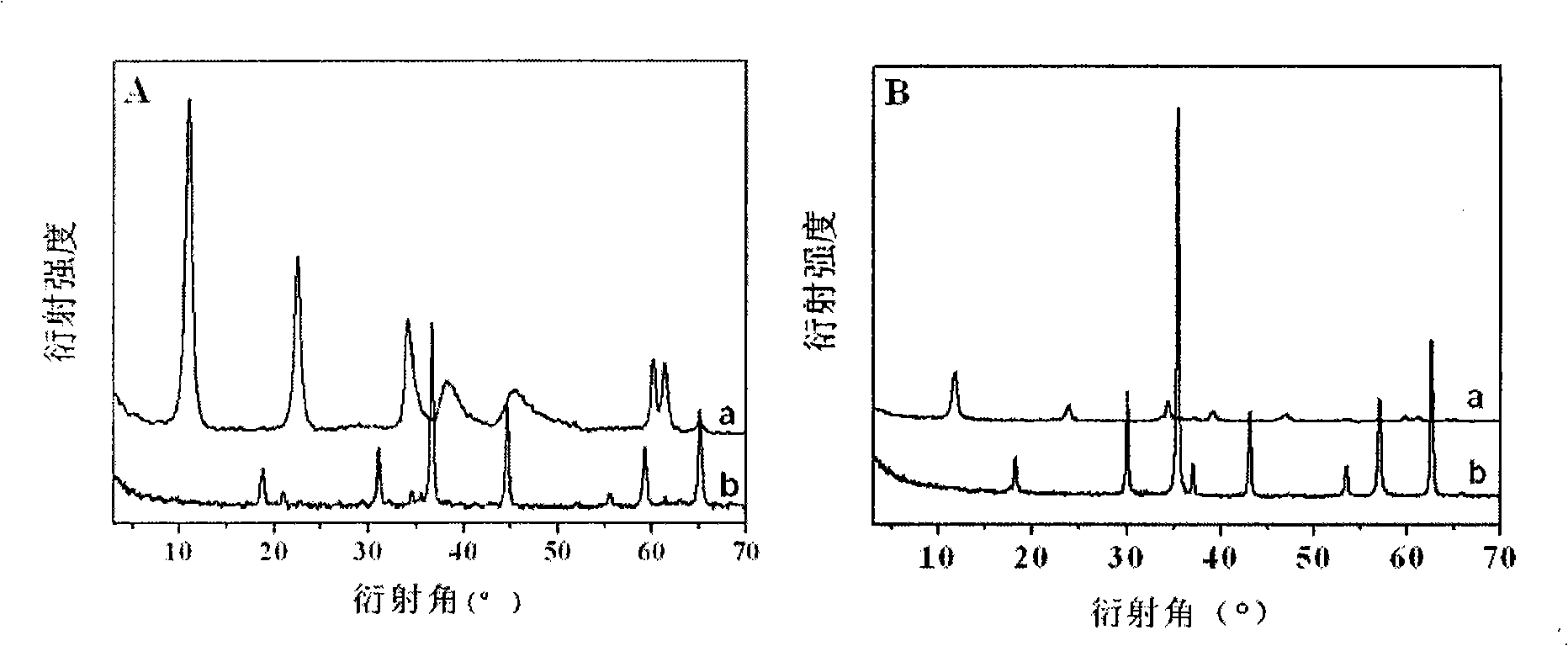

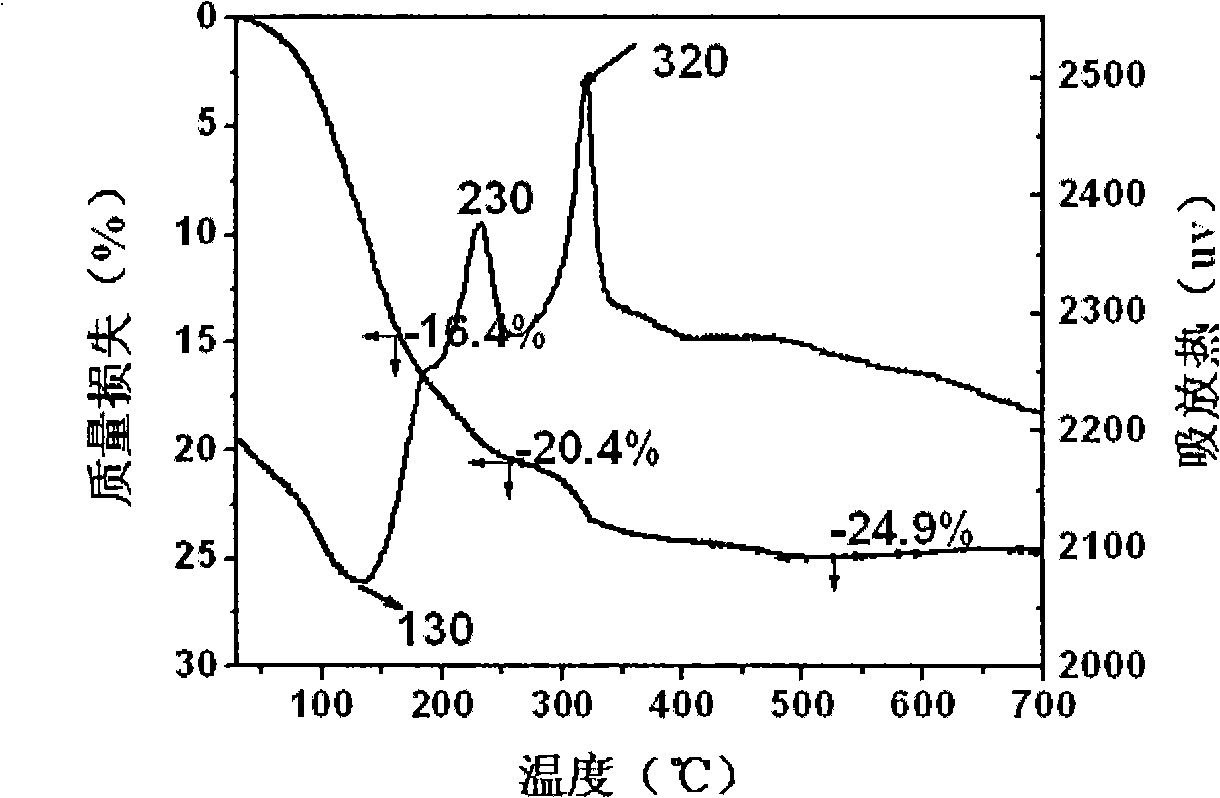

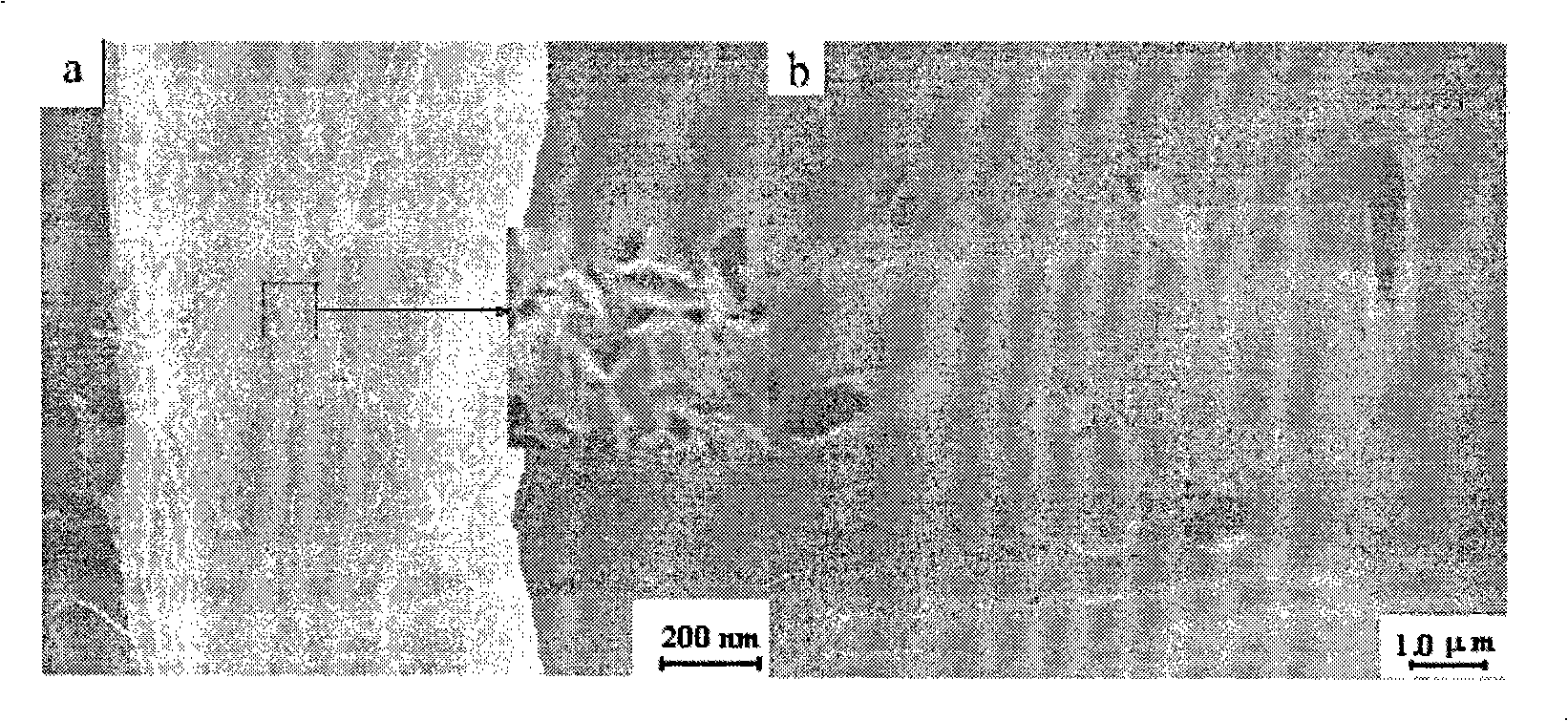

[0036] C. Place the adsorption assembly in a muffle furnace, raise the temperature of the muffle furnace to 1100° C. at a heating rate of 5.0° C. / min, and keep it warm for 2 hours to obtain cob...

Embodiment 2

[0040] A. Weigh 4.1 grams of Co(NO 3 ) 2 ·6H 2 O, 3.9 g FeSO 4 ·7H 2 O and 2.8 g Fe 2 (SO 4 ) 3 Put into 50.0 ml of high-quality wood pulp with a concentration of 1.0% and stir until the solid mixture is fully dissolved. Separately prepare 2.5M NaOH and 1.8 M NaOH with deoxygenated deionized water 2 CO 3 50.0 ml of the mixed alkali solution, under the protection of nitrogen and vigorous stirring, the mixed alkali solution was slowly added dropwise to the above-mentioned three-necked flask containing the salt solution until the pH ≈ 10.5, and then continued to stir for 6.0 hours.

[0041] B. After the stirring is completed, the product is allowed to stand for crystallization at room temperature for 16.0 hours.

[0042] C. Filter the above mixture, and wash with deionized water and absolute ethanol for 3 times successively.

[0043] D, vacuum drying the solid matter to obtain Co 2+ Fe 2+ Fe 3+ - LDH / paper fiber adsorption assembly.

[0044] E. Place the adsorption ...

Embodiment 3

[0047] A. Weigh 5.8 grams of Co(NO 3 ) 2 ·6H 2 O, 5.6 g FeSO 4 ·7H 2 O and 8.1 g Fe 2 (SO 4 ) 3 Put into 50.0 ml of high-quality wood pulp with a concentration of 1.0% and stir until the solid mixture is fully dissolved. Separately prepare 2.5M NaOH and 2.0M NaOH with deoxygenated deionized water 2 CO 3 50.0 ml of the mixed alkali solution, under the protection of nitrogen and vigorous stirring, the mixed alkali solution was slowly added dropwise to the above-mentioned three-necked flask containing the salt solution until the pH ≈ 10.5, and then continued to stir for 6.0 hours.

[0048] B. After the stirring is completed, the product is allowed to stand for crystallization at room temperature for 16.0 hours.

[0049] C. Filter the above mixture, and wash with deionized water and absolute ethanol for 3 times successively.

[0050] D. Vacuum dry the solid matter to obtain Co 2+ Fe 2+ Fe 3+ - LDH / paper fiber adsorption assembly.

[0051] E. Place the adsorption asse...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tube chief | aaaaa | aaaaa |

| Tube chief | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com