Electric stove for smelting titanium slag

An electric furnace, titanium slag technology, applied in electric furnace, electric furnace heating, furnace and other directions, can solve the problems of large change of viscosity with temperature and smelting progress, high chemical activity of charge, and large change of electrical conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

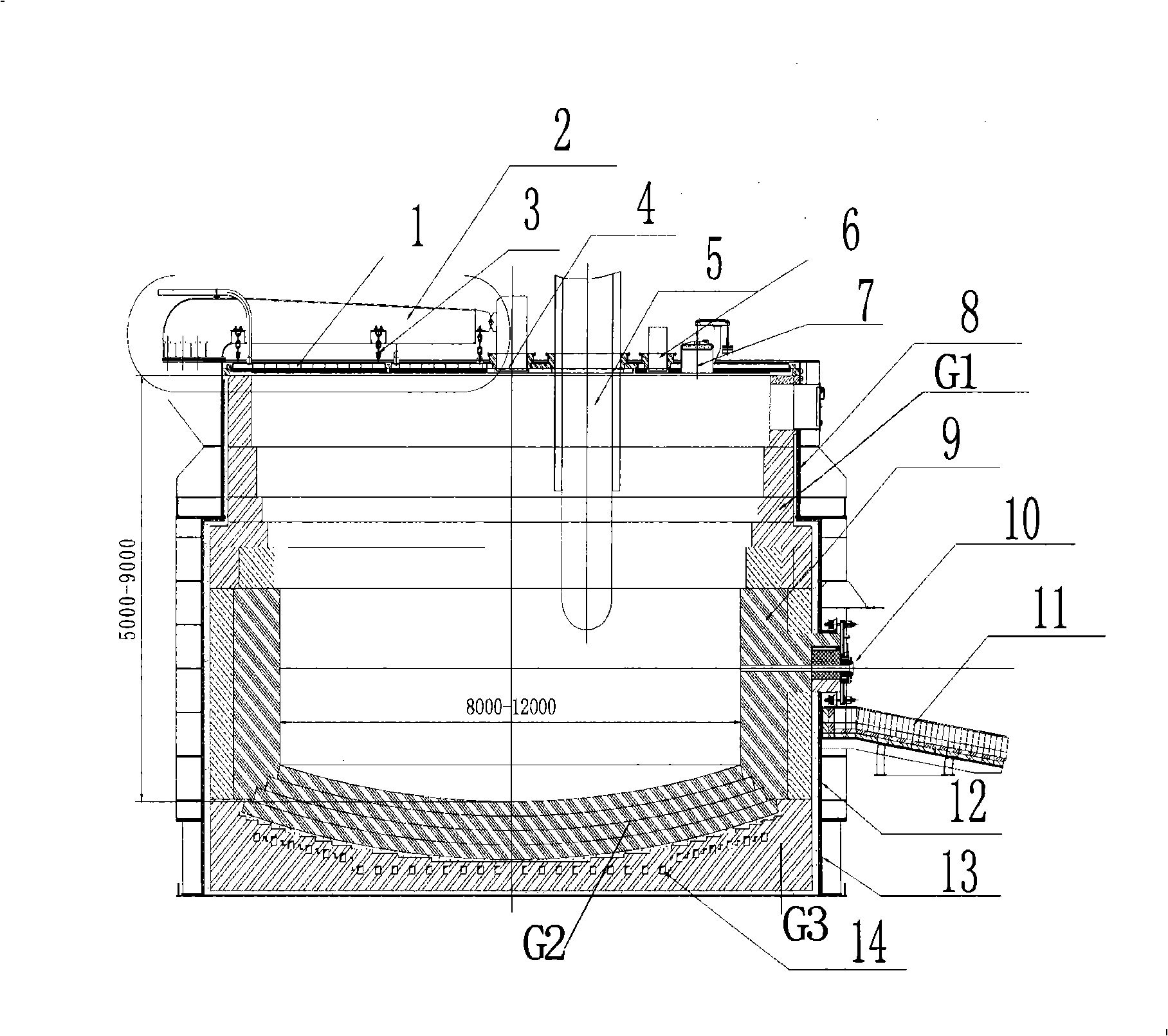

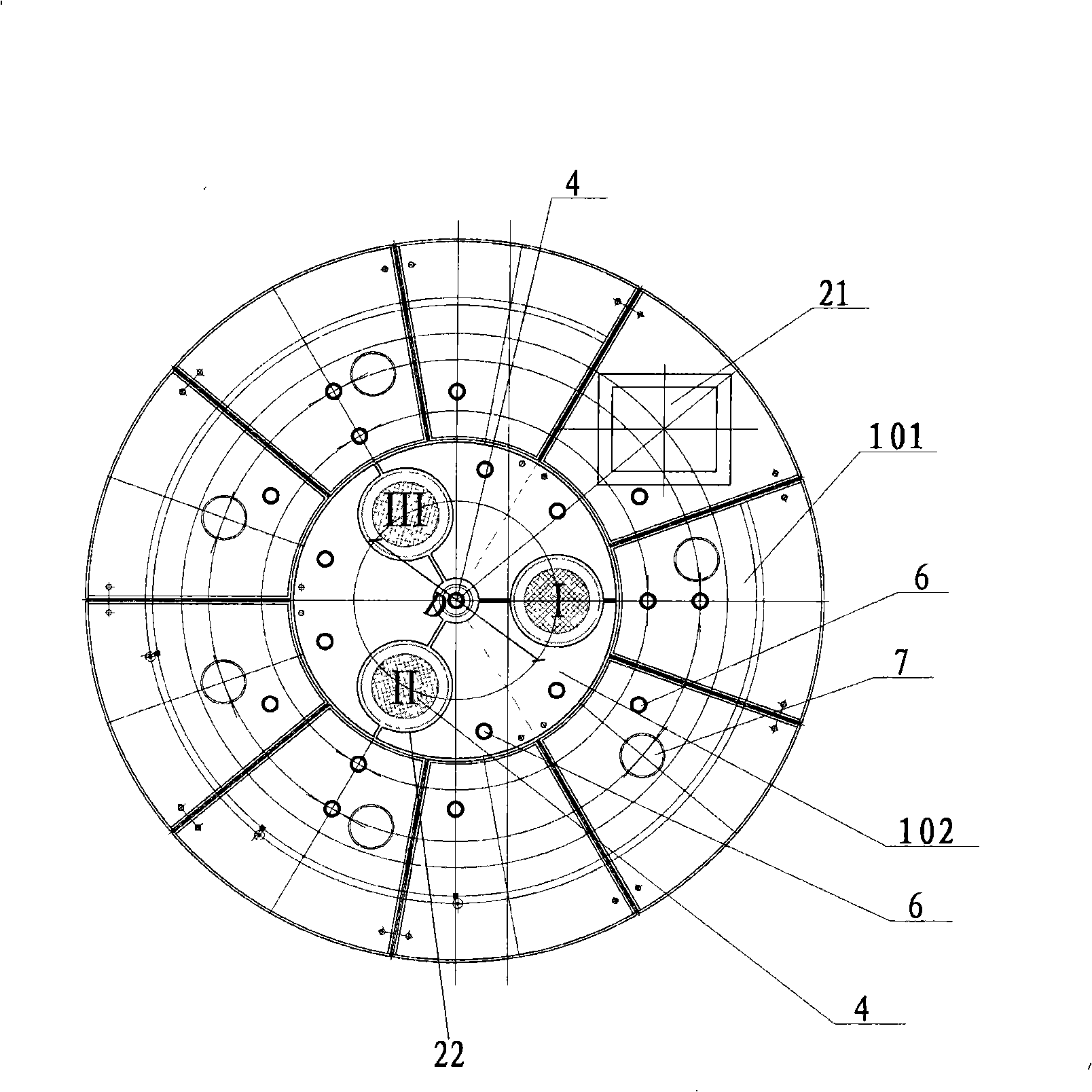

[0020] figure 1 is a schematic sectional view showing an electric furnace for smelting titanium slag according to an embodiment of the present invention. figure 2 is a schematic plan view showing the structure of the furnace roof.

[0021] refer to figure 1 , The electric furnace for smelting titanium slag according to the embodiment of the present invention is mainly composed of a furnace cover, a furnace shell and a furnace bottom. Such as figure 1 The shown electric furnace for smelting titanium slag according to an exemplary embodiment of the present invention is a large electric furnace for smelting titanium slag, the diameter of the pole center circle is 2500mm-3500mm, and the operating power of the electric furnace is 15000kVA-30000kVA.

[0022] In the embodiment according to the present invention, the furnace shell is mainly divided into upper, mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com