Closed electric furnace and titanium slag smelting process

A closed furnace, titanium slag technology, applied in the field of titanium chemical industry, can solve the problems of unstable furnace conditions, large changes in electrical conductivity, and large amplitudes, and achieve the effect of stable furnace conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

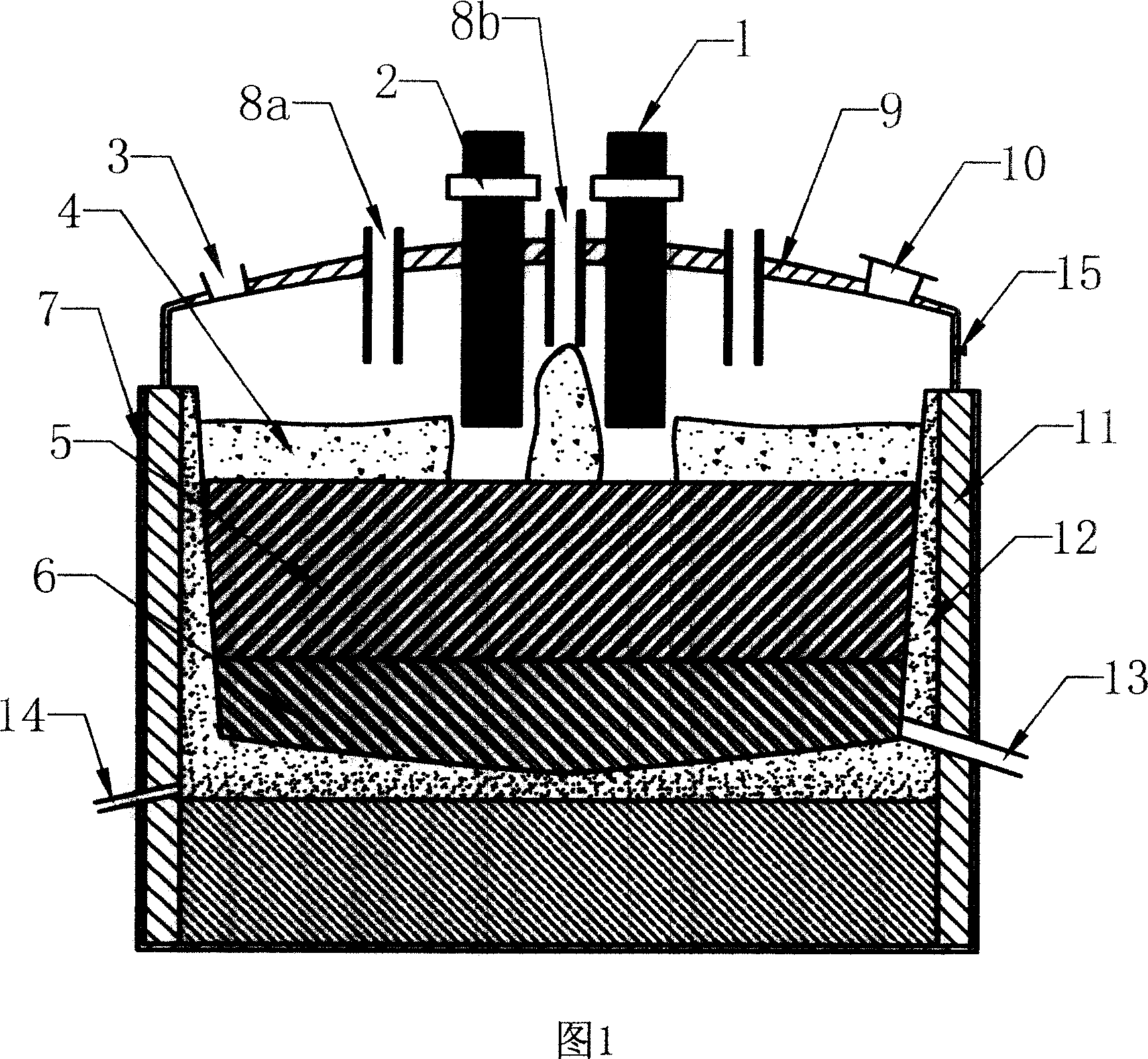

[0026] The airtight electric furnace provided by the present invention includes a closed body composed of a casing 7, a furnace cover 9, and a furnace wall 11. The electrode 1 is clamped by a holder 2 and inserted vertically into the furnace body. The upper part of the furnace body is also provided with a furnace gas pipeline 3, a side Feed pipe 8a, intermediate feed pipe 8b, and a slag outlet 13 and an iron taphole 14 are arranged at the lower part of the furnace body. The inner wall of the furnace wall 11 has a layer of protective slag 12 to protect the furnace wall.

[0027] Manhole 10 and observation hole 15 can also be set according to actual conditions.

[0028] Among them, the electrode holes and the furnace cover adopt flexible dry seals, and the flexible dry seals refer to the use of graphite powder, expanded graphite, titanium slag, titanium concentrate, gravel and other materials as sealing materials, and its characteristics are: high melting point, friction The coe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com