Method for preparing Pd/carbon catalyst for hydrofinishing of coarse isophthalic acid

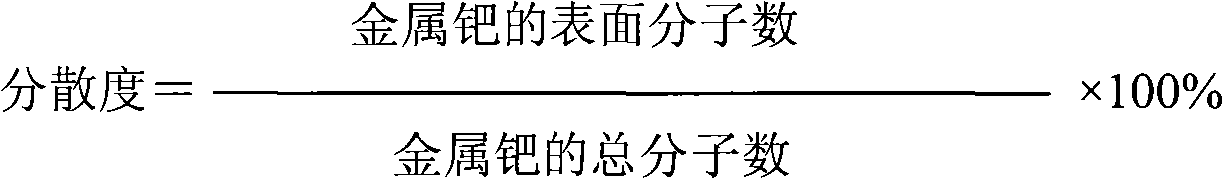

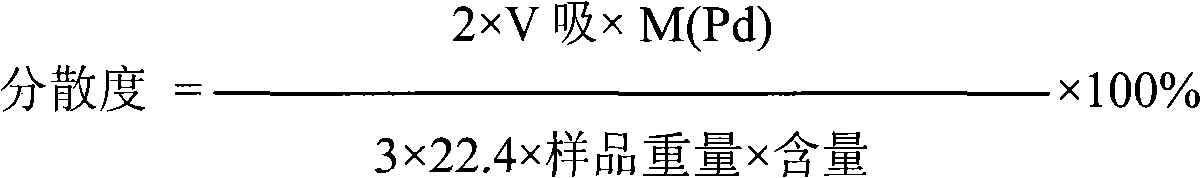

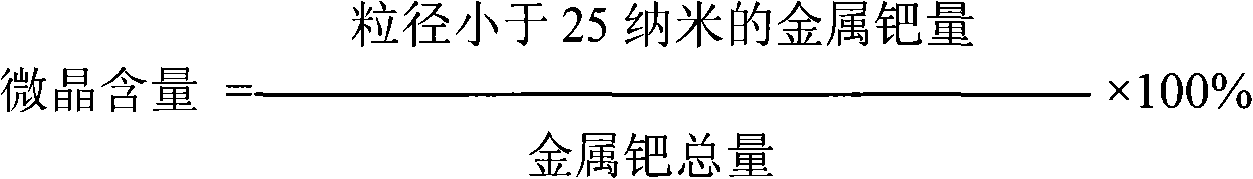

A crude isophthalic acid, hydrogenation refining technology, applied in physical/chemical process catalysts, separation/purification of carboxylic acid compounds, chemical instruments and methods, etc., can solve the problem of low dispersion of metal Pd, low crystallite content, etc. problems, to achieve the effect of easy environmental protection, high microcrystalline content and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] 100 grams of 4 to 8 mesh, specific surface 800 to 1200 meters 2 The coconut shell activated carbon per gram is washed with 0.1N nitric acid at 80°C, then washed with water until neutral, and dried at 120°C for 2 to 8 hours. Prepare NO with sodium nitrite and water 2 - The impregnation solution with a concentration of 0.2N is used to impregnate activated carbon with equal volume for 8 hours, and then dried at 80-120°C for 2-8 hours for later use.

[0040] Then prepare 40 milliliters of chloropalladium acid solution whose palladium weight content is 0.5%, adjust the pH value to between 4 and 6 with alkali, make it form palladium glue, stabilize it for 10 to 200 minutes, spray the palladium glue The catalyst precursor was obtained on the above treated activated carbon. After the catalyst precursor was aged overnight, 20 grams of 5% by weight sodium formate and 200 grams of pure water were used to prepare a reducing solution. The catalyst precursor was immersed in the re...

Embodiment 2

[0042] Activated carbon is washed with 5.0N nitric acid, and the washing temperature is 80°C, then washed with water until neutral, and all the other are the same as in Example 1.

Embodiment 3

[0044] Activated carbon is washed with 5.0N phosphoric acid, and the washing temperature is 80° C., then washed with water until neutral, and all the other are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com