Preparation method iron based SmFeAsO1-xFx superconducting wire

A smfeaso1-xfx, superconducting wire technology, applied in the usage of superconducting elements, superconducting devices, superconducting/high-conducting conductors, etc., can solve the problem of low preparation success rate, small sealing and restraint effect, poor material performance, etc problems, to achieve the effect of high preparation success rate, improved critical current density and good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] An iron-based SmFeAsO 1-x f x The preparation method of superconducting wire rod, its operation step is: a, prepare material according to prepare iron-based superconducting material SmFeAsO 1-x f x , the stoichiometric ratio of x=0.2, weigh the raw materials SmAs, Fe, Fe respectively 2 o 3 , FeF 3 , after grinding and mixing evenly, put the tantalum tube into it, fill it up, press it tightly, and seal both ends of the tantalum tube, and welding can be used for sealing; Then draw it into a wire rod with a diameter of 2mm; c. Sintering Place the wire rod in a quartz tube for vacuum sealing, put it in a sintering furnace, and raise the temperature to 1150°C at a rate of 100°C / hour under an inert protective atmosphere, and keep it warm for 48 hours. Then cool with the furnace to get SmFeAsO 0.8 f 0.2 superconducting wire.

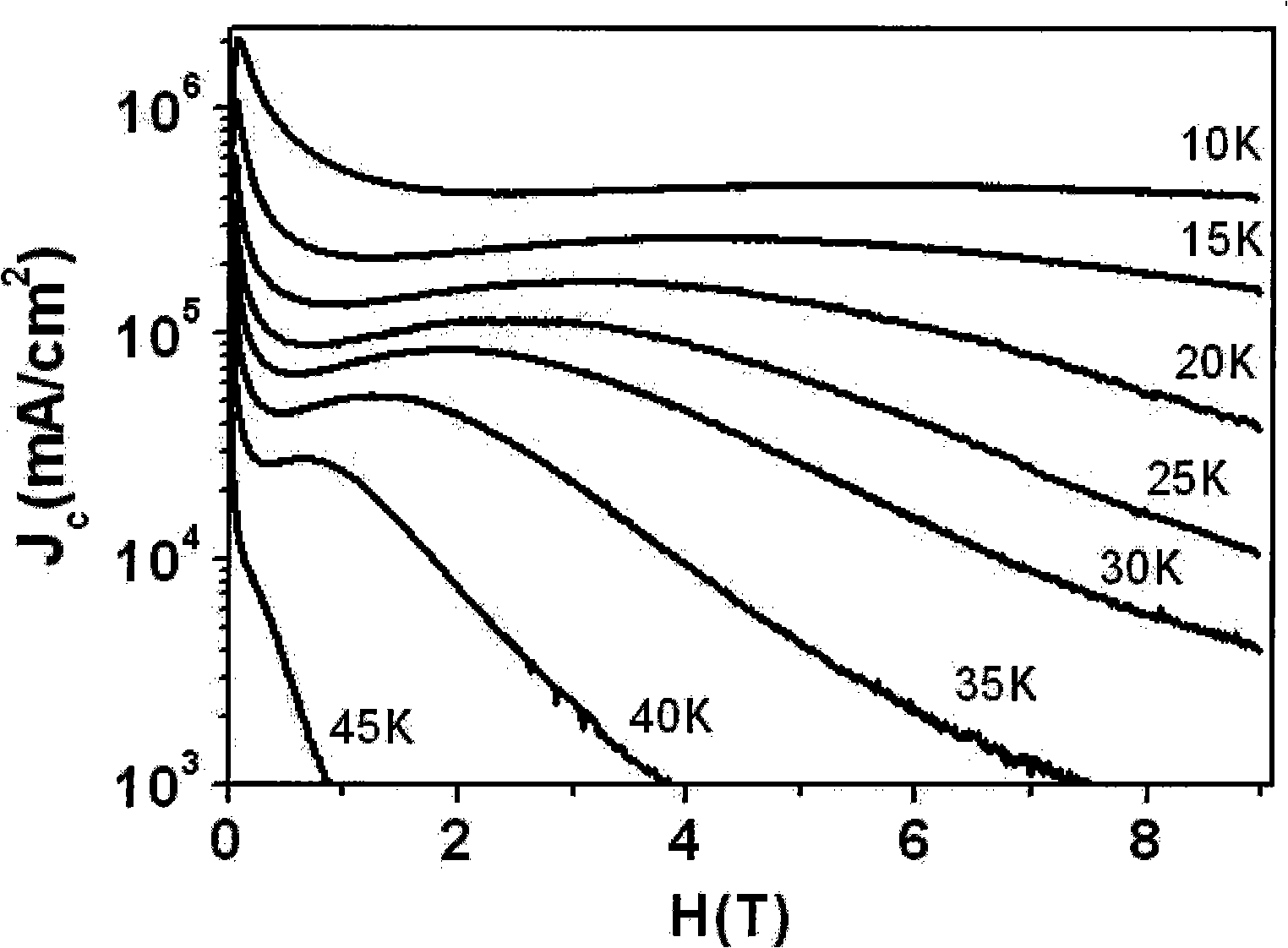

[0023] figure 1 For the SmFeAsO prepared by the method of this example 0.8 f 0.2 Scanning electron microscope (SEM) image of a superconductin...

Embodiment 2

[0025] A specific embodiment of the present invention is: an iron-based SmFeAsO 1-x f x The preparation method of superconducting wire rod, its operation step is: a, prepare material according to prepare iron-based superconducting material SmFeAsO 1-x f x , the stoichiometric ratio of x=0.15, weigh raw material SmAs, Fe, Fe respectively 2 o 3 , FeF 3 , after grinding and mixing evenly, put it into the tantalum tube, fill it up, press it tightly, and seal both ends of the tantalum tube; Wire; c. Sintering Put the wire in a quartz tube and vacuum seal it, put it into a sintering furnace, and raise the temperature to 1170°C at a rate of 150°C / hour under an inert protective atmosphere, keep it warm for 36 hours, and then cool with the furnace to obtain SmFeAsO 0.85 f 0.15 superconducting wire.

Embodiment 3

[0027] An iron-based SmFeAsO 1-x f x The preparation method of superconducting wire rod, its operation step is: a, prepare material according to prepare iron-based superconducting material SmFeAsO 1-x f x , the stoichiometric ratio of x=0.2, weigh the raw materials SmAs, Fe, Fe respectively 2 o 3 , FeF 3 , after grinding and mixing evenly, put it into the tantalum tube, fill it up, press it tightly, and seal both ends of the tantalum tube; Wire; c. Sintering Put the wire in a quartz tube and vacuum seal it, put it into a sintering furnace, and raise the temperature to 1170°C at a rate of 120°C / hour under an inert protective atmosphere, keep it warm for 40 hours, and then cool with the furnace to obtain SmFeAsO 0.8 f 0.2 superconducting wire.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| superconducting critical temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com