Hydrocarbons recovery method

A hydrocarbon recovery and hydrocarbon technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of inconvenient operation, large adsorbent amount, and increased equipment investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

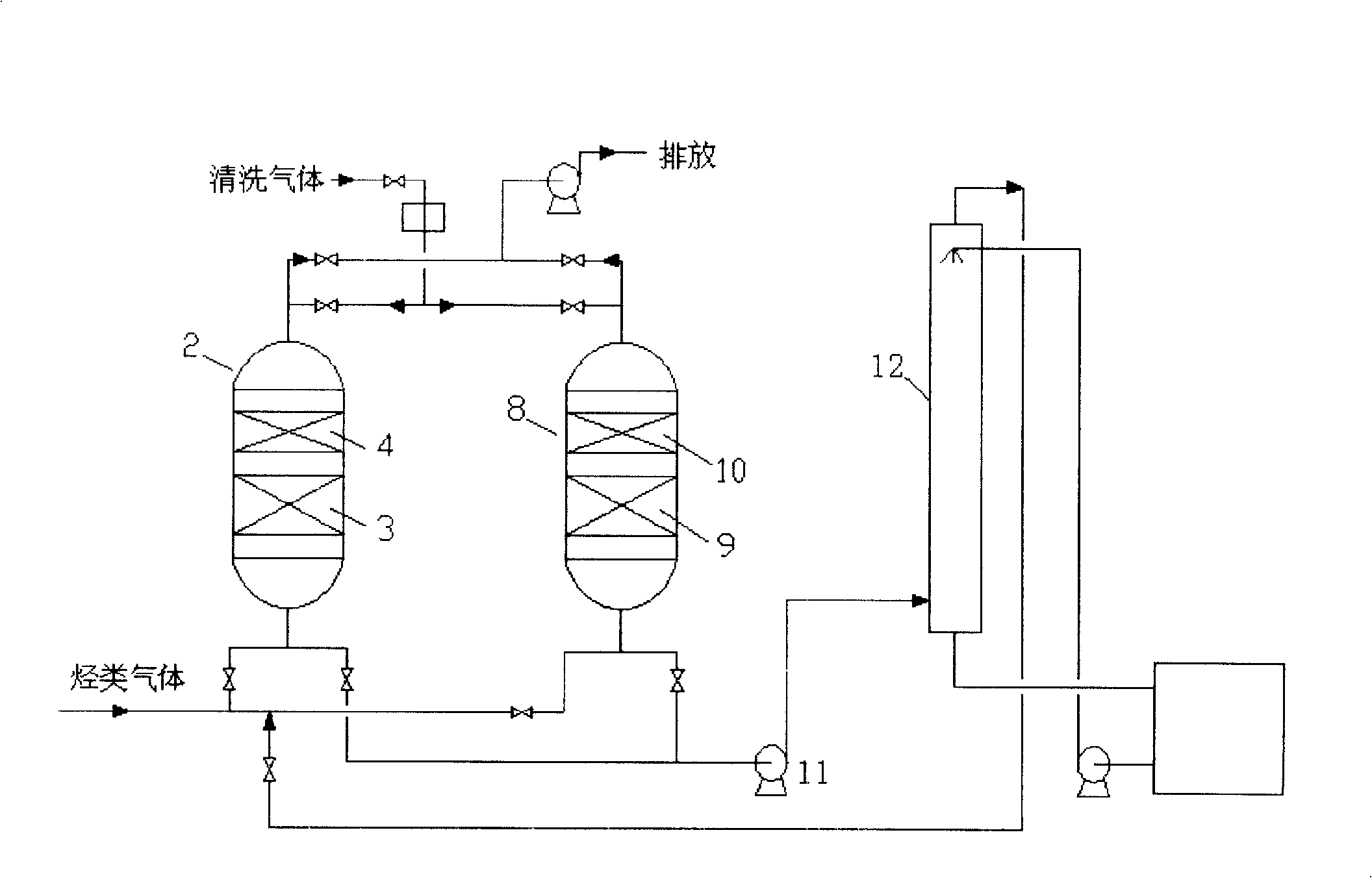

Embodiment 1

[0029] In this embodiment, the two-stage adsorption method is used to process the breathing gas of the oil tank, and the gas is operated from bottom to top. The total hydrocarbon concentration is 35% (volume), and the vacuum desorption gasoline absorption method is used to recover hydrocarbons. The lower adsorbent is commercially available silica gel. , specific surface area 713m 2 / g, pore volume 0.39ml / g, average pore diameter 2.2nm. The upper layer is commercially available activated carbon with a specific surface area of 1077m 2 / g, the pore volume is 0.52ml / g, the average pore diameter is 1.5nm, and the absorption liquid is gasoline. The volume ratio of silica gel adsorbent to activated carbon adsorbent is 60:40, and the total volume space velocity is 1000h -1 , Adsorption takes 2h to be regenerated. After the process is processed, the total hydrocarbon concentration of the outlet gas is less than 20ppm, and the recovery rate is 100% (by mass). The adsorption ambien...

Embodiment 2

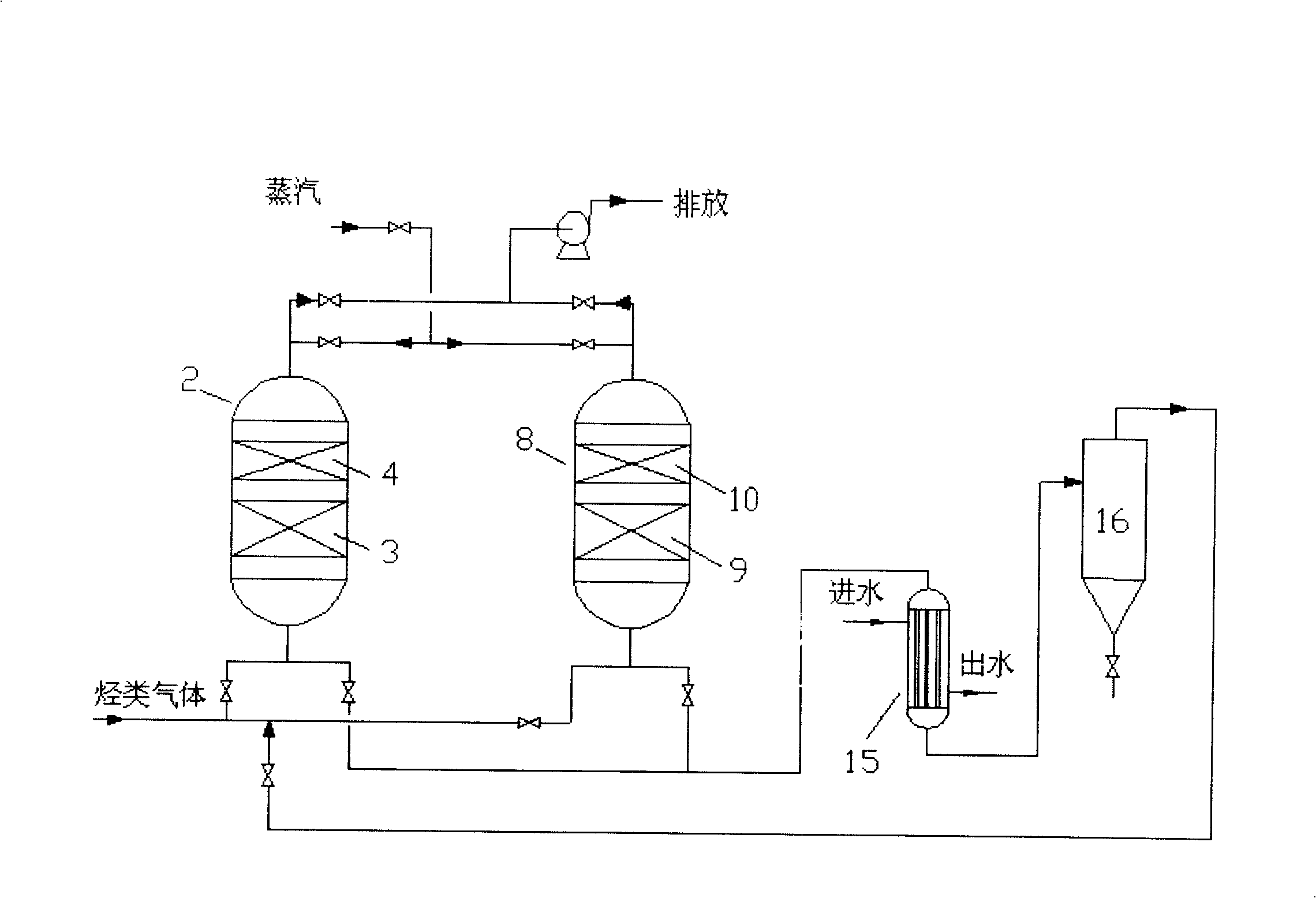

[0033] In the present embodiment, the waste gas is 1% (volume) toluene, and the lower layer is a commercially available zeolite with a specific surface area of 750m 2 / g, the pore volume is 0.4ml / g, the upper layer is activated carbon, and the specific surface area is 884m 2 / g, pore volume 0.4ml / g, average pore diameter 1.5nm, steam desorption, condensation temperature 25°C, volume ratio of zeolite to activated carbon 30:70, total volume space velocity 3000h -1 . After being treated by the process, the outlet toluene concentration is less than 3ppm, and the recovery rate is more than 99.99% (mass). The adsorption ambient temperature is 28°C, the lower adsorption temperature is 35°C, and the activated carbon layer temperature is 45°C.

Embodiment 3

[0035] By the process of embodiment 1, the volume ratio of silica gel adsorbent and active carbon adsorbent is 80: 20, and total volume space velocity is 800h -1 , Adsorption takes 2 hours to regenerate. After the process is processed, the total hydrocarbon concentration of the outlet gas is less than 20ppm, and the recovery rate is 100% (by mass). The adsorption ambient temperature is 22°C, the maximum temperature of the silica gel adsorption bed is 40°C, and the temperature of the activated carbon bed is 50°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com