Production method of silicon carbide fiber with high temperature tolerance

A technology of silicon carbide fiber and manufacturing method, which is applied in the direction of chemical characteristics of fibers, textiles and papermaking, etc., can solve the problems of difficult to obtain SiC fiber products, and achieve the effect of reducing oxygen content, convenient operation and low oxygen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

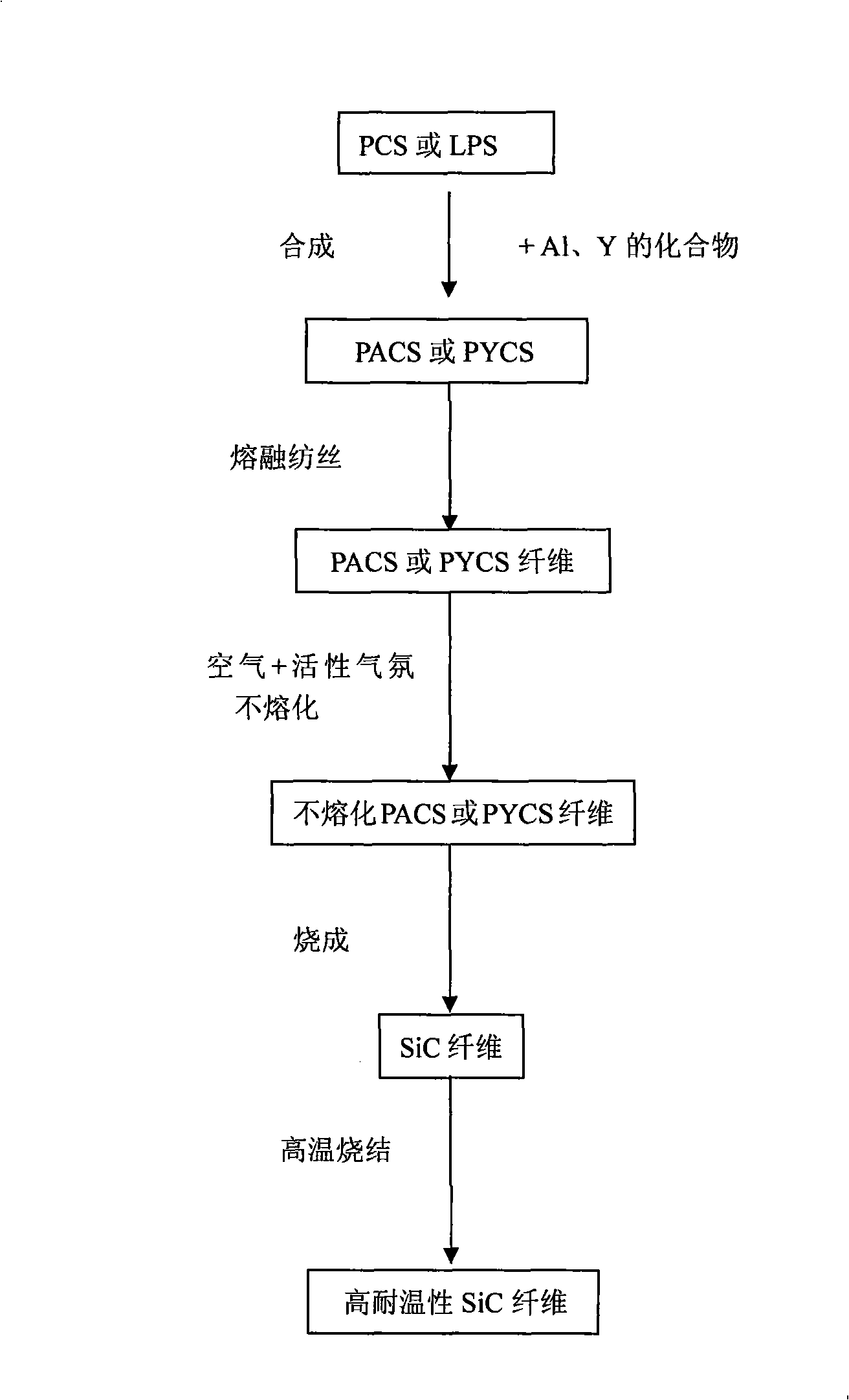

Method used

Image

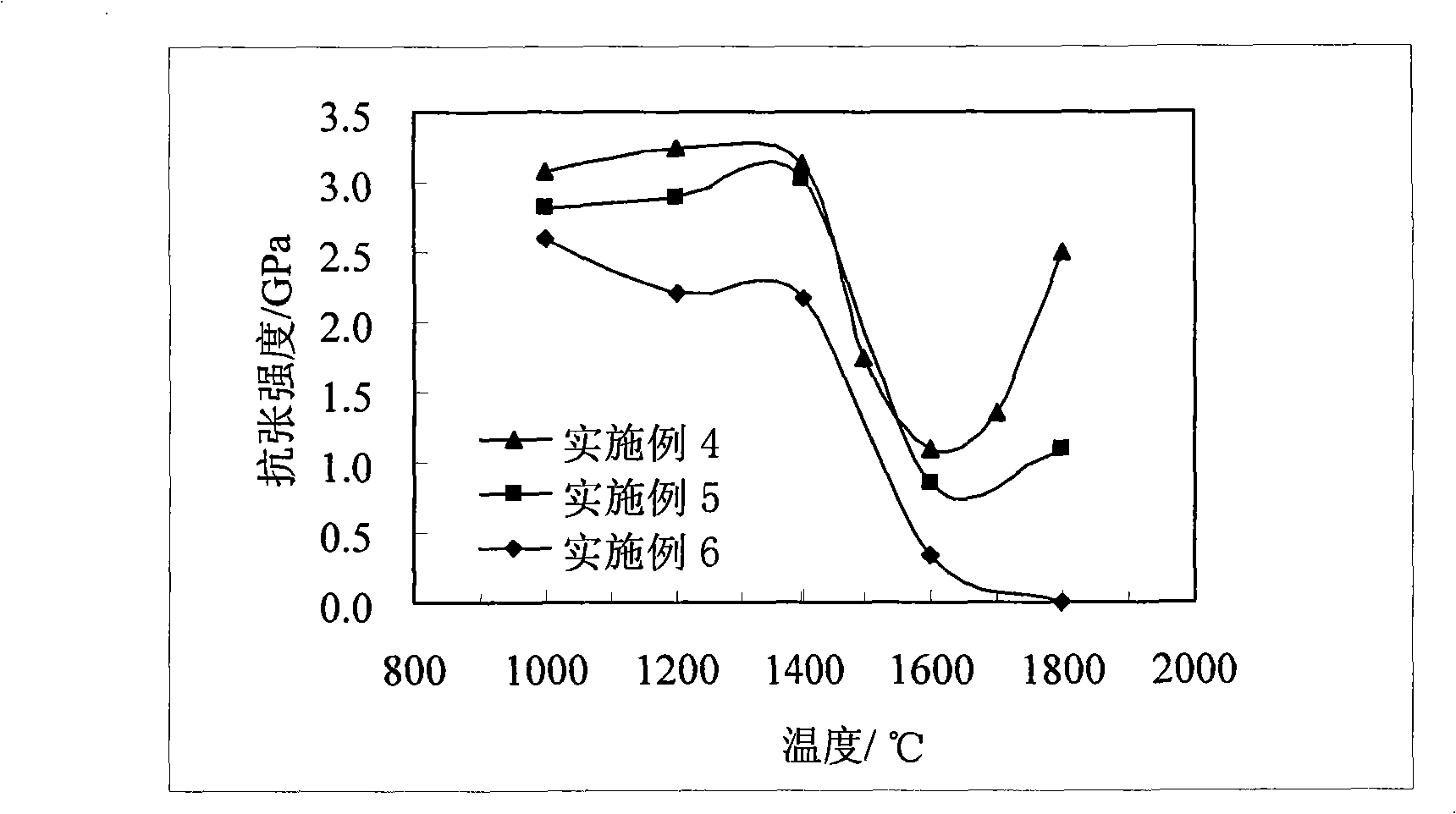

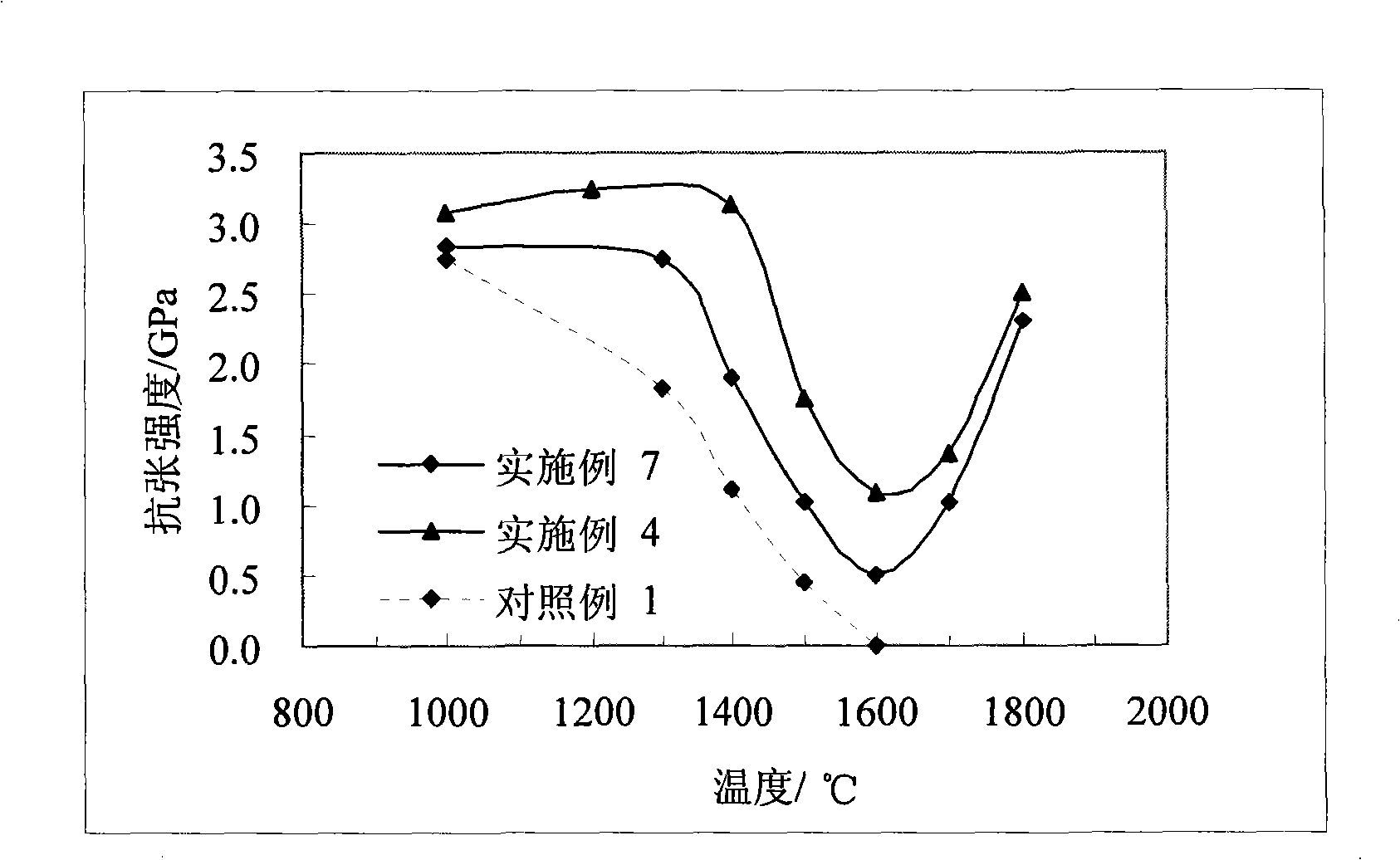

Examples

reference example 1

[0042] Take 1000g of polydimethylsilane and place it in a reaction kettle, and after passing through high-purity nitrogen to replace the air, slowly heat to 460°C, and keep warm at this temperature for 4 hours for pyrolysis polymerization. The crude product was dissolved in xylene and then filtered. The filtrate was distilled at about 200°C to remove the solvent and then distilled to 350°C under reduced pressure. After cooling, about 520g of light yellow resinous polycarbosilane PCS was obtained. The number average molecular weight Mn was 1840, and the softening point was 210-225°C.

Embodiment 1

[0044] Take 1,000 g of polydimethylsilane and place it in a reaction kettle. After replacing the air with high-purity nitrogen, it is slowly heated to 420° C., and thermally decomposed and polymerized at this temperature for 5 hours. The crude product was dissolved in xylene and filtered. The filtrate was distilled at about 200°C to remove the solvent. After cooling, about 550 g of light yellow resinous polycarbosilane PCS was obtained. The number average molecular weight Mn was 990 and the softening point was 110-117°C. Mixing PCS with aluminum acetylacetonate Al(acac) 3 It was co-dissolved in xylene at a mass ratio of 1:0.08, heated to 350°C while stirring under the protection of high-purity nitrogen, and reacted at 350°C for 4 hours. After distilling off small molecules, the light yellow product PACS was obtained, and its Mn was 1704, the softening point is 205-218°C.

Embodiment 2

[0046] Take 1000g of polydimethylsilane and put it in a distillation reaction kettle. After replacing the air with high-purity nitrogen, heat it slowly to 400°C, and pyrolyze it at this temperature for 4 hours, and collect the decomposition products by condensation while pyrolysis. It is a mixture of low molecular silanes (referred to as LPS), and the pyrolysis reaction yield is 74%. LPS is a transparent liquid at room temperature, with a boiling point of 60-300°C and a number-average molecular weight of 100-600. Mixing LPS with aluminum acetylacetonate Al(acac) 3 After dissolving and mixing at a mass ratio of 1:0.10, heat the reaction under the protection of high-purity nitrogen and gradually raise the temperature to 450° C., and keep the reaction at 450° C. for 4 hours. The crude product was dissolved in xylene and then filtered, heated to distill off the solvent, and then distilled under reduced pressure at 320°C to remove a small amount of low-molecular substances. After ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Boiling point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com