Yttrium coated stable zirconium oxide powder, preparation and application thereof

A technology of yttrium-stabilized zirconia and stabilized zirconia, which is applied in the field of coating preparation, can solve the problems of poor thermal stability and easy sintering, and achieve the effects of good anti-sintering performance, low production cost and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

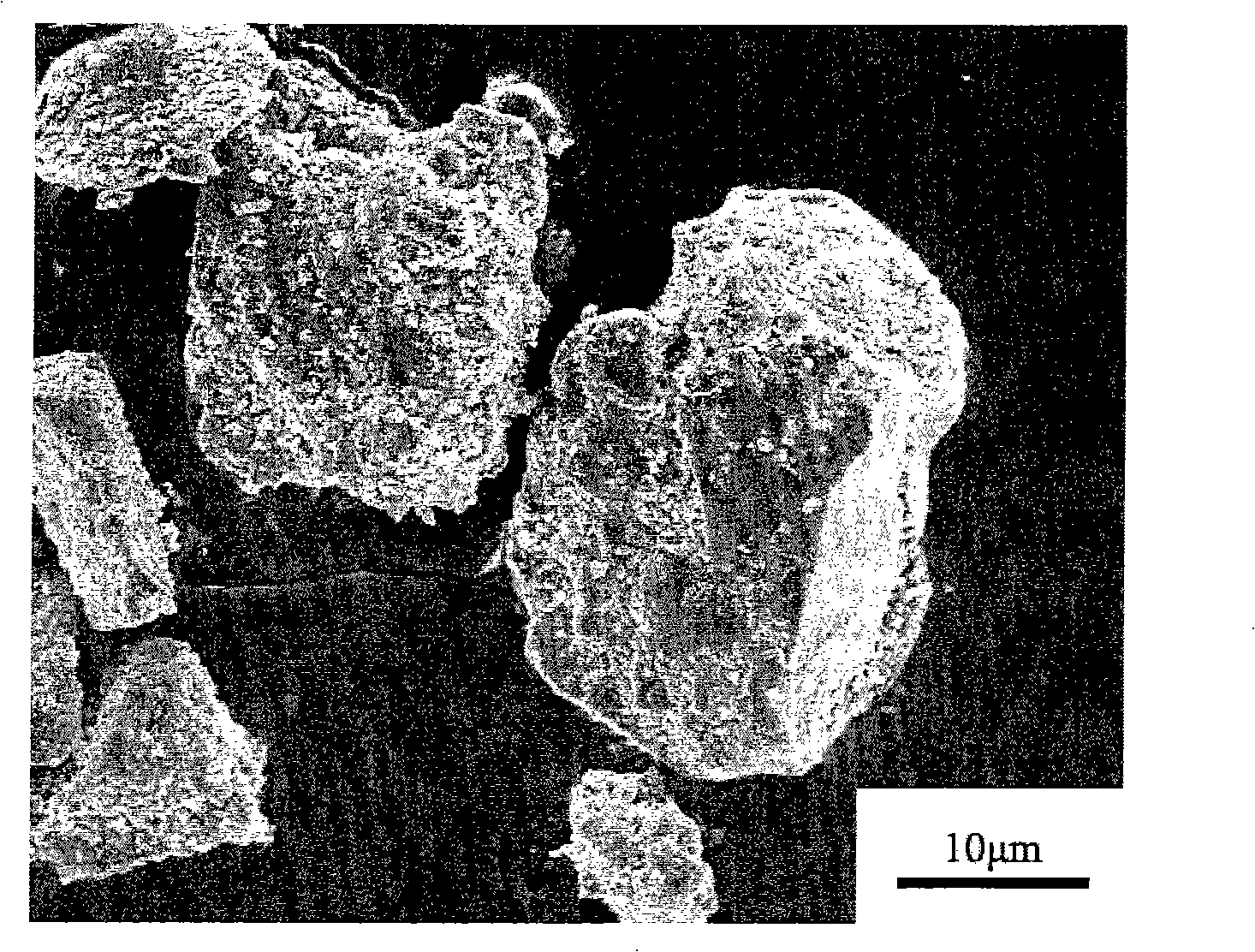

Image

Examples

Embodiment 1

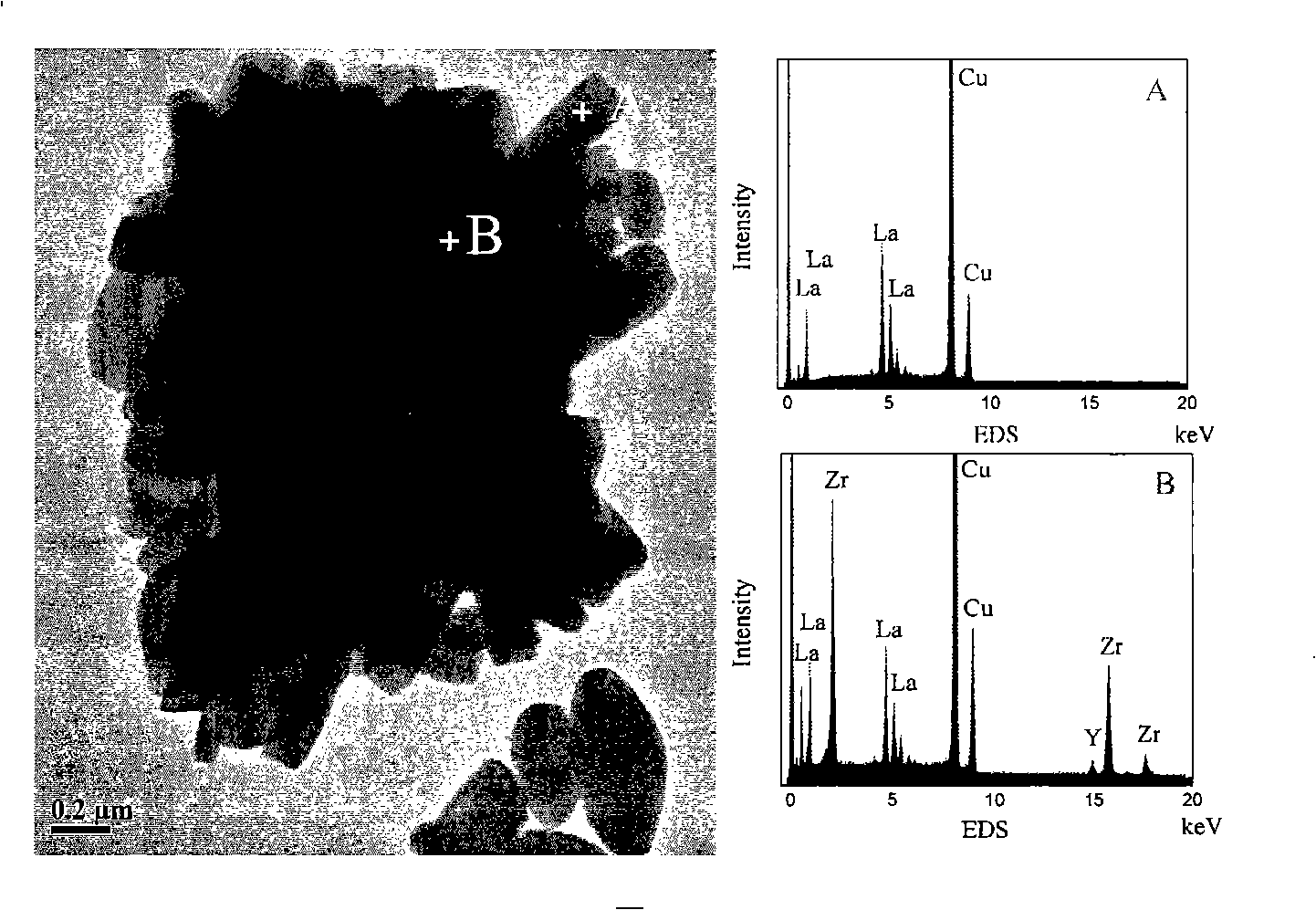

[0035] Disperse 50g of YSZ powder in 100g of lanthanum nitrate solution with a concentration of 0.3mol / L, ultrasonically disperse for 30min, weigh urea and add it to the above solution, urea and La 3+ The concentration ratio was 5:1. The suspension was heated in a water bath at 90°C with constant stirring and kept for 30 hours. After cooling, it was centrifuged and dried in an oven at 70°C for 24 hours.

[0036] Weigh 500 g of the powder obtained above, add 50 g of PVA with a concentration of 5 wt %, grind with a mortar, and sieve to obtain a thermal spray powder with relatively uniform particle size distribution and good fluidity.

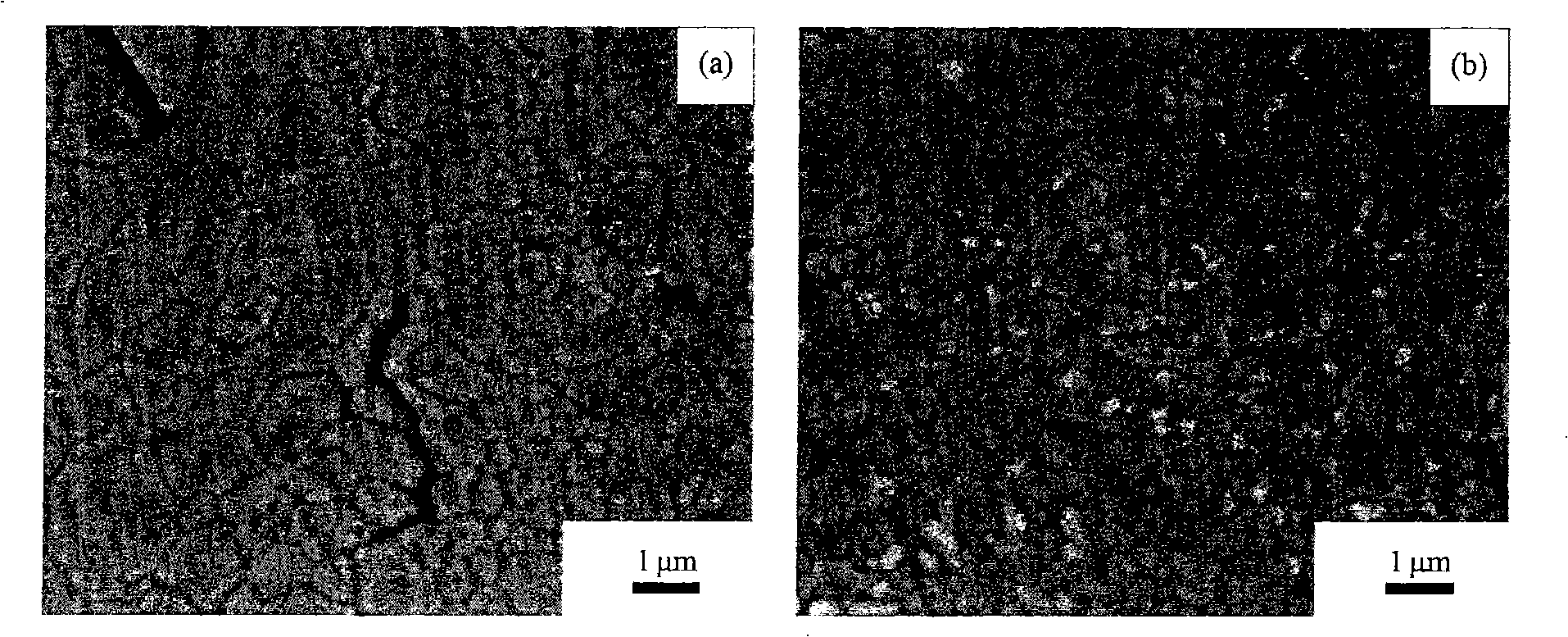

[0037] The alloy substrate is selected as the substrate, and the substrate is cleaned with ethanol before spraying, and after sandblasting, the treated sample is immediately plasma sprayed. The spraying powder adopts the above-mentioned 100-200 mesh modified powder. For the plasma spraying process, the current is 660A, the spraying distance is 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com