Preparation for 2,6-diamino-3, 5-di nitryl pyridine

A technology of dinitropyridine and diaminopyridine, which is applied in the field of preparation of nitropyridine, can solve the problems of low yield, difficult industrial production, and low product purity, and achieve the effects of less by-products, less oxidation resistance, and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

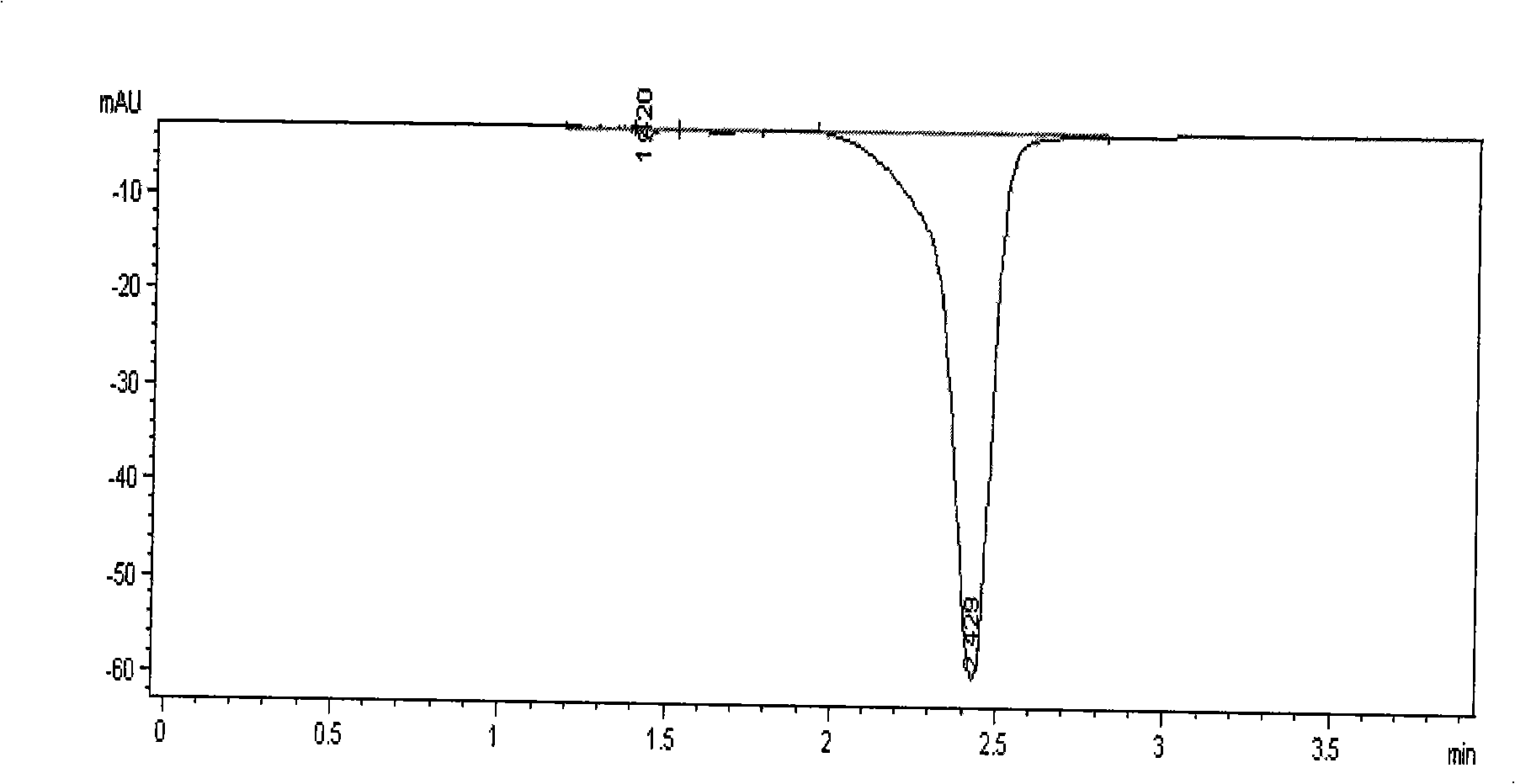

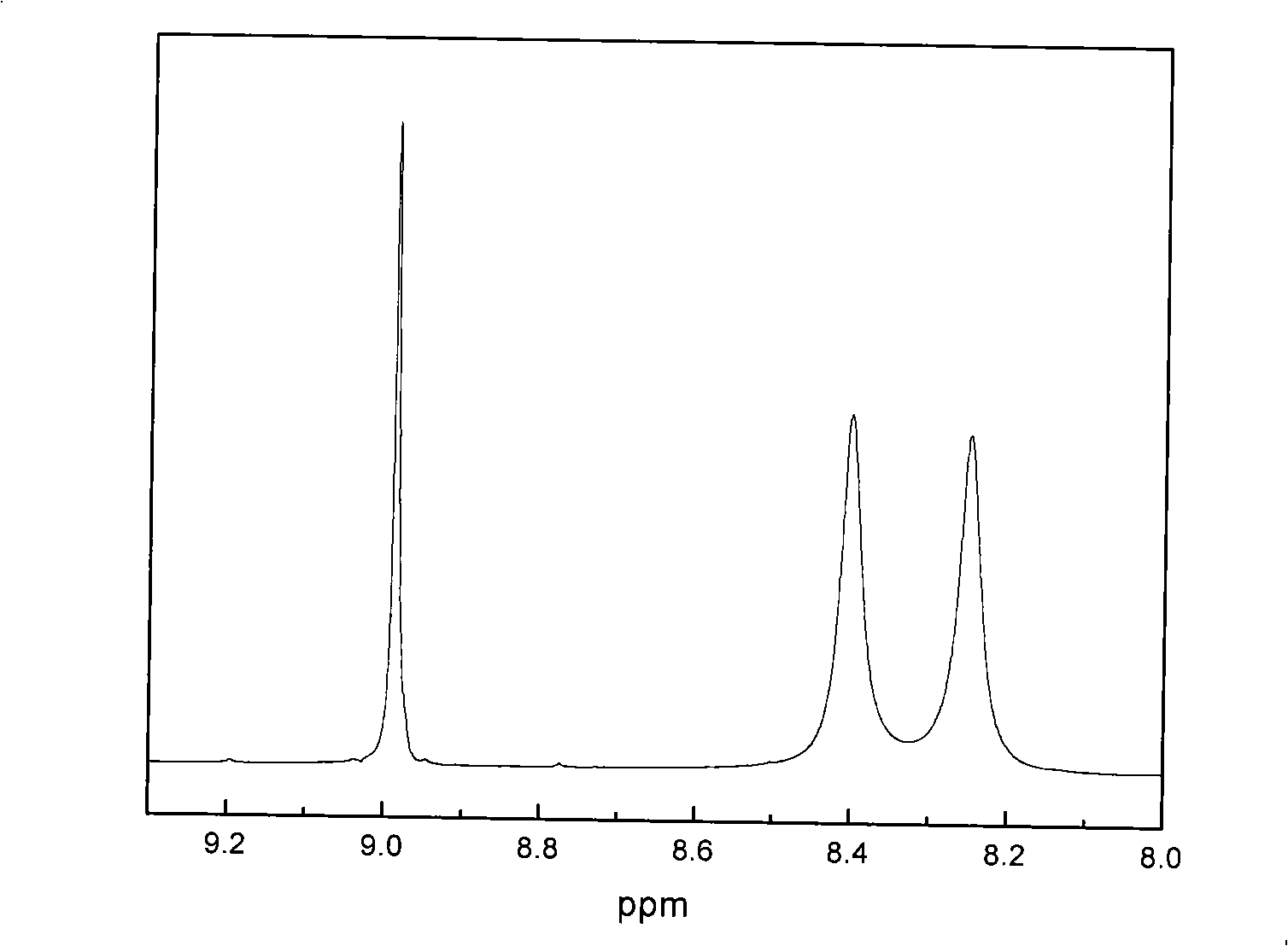

Image

Examples

specific Embodiment approach 1

[0010] Specific embodiment one: present embodiment 2,6-diamino-3, the preparation method of 5-dinitropyridine is realized according to the following steps: one, 2,6-diaminopyridine and the concentrated sulfuric acid mass concentration that mass concentration is 98% Add mole ratio 1~2:1 to absolute ethanol in order to mix and stir, the pH value is 3~5, vacuum filter after cooling to room temperature, and then dry the solid phase under vacuum condition of 40~60℃ for 22~ 26h, the sulfate salt of 2,6-diaminopyridine was obtained; the sulfate salt of 2,2,6-diaminopyridine was added to oleum at 0°C in a molar ratio of 1:2, and the temperature was kept <30°C, and then dripped Add fuming nitric acid with a mass concentration of 95%, keep the temperature <15°C, and react for 3 to 6 hours to obtain the mixture; 3. Stir the mixture at a rate of 600 to 800 r / min under ice quenching until it forms a Foamy yellow liquid, then carry out vacuum filtration, and then dry the solid phase under v...

specific Embodiment approach 2

[0011] Specific embodiment two: the difference between this embodiment and specific embodiment one is that in step one, 2,6-diaminopyridine and concentrated sulfuric acid with a mass concentration of 98% are sequentially added to absolute ethanol in a molar ratio of 1.5:1 and mixed and stirred , the pH value was 4, vacuum filtration was performed after cooling to room temperature, and then the solid phase was dried at 50° C. for 24 hours under vacuum conditions. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0012] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the oleum at 0° C. in step 2 is cooled in an ice-salt bath. Other steps and parameters are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com