Te/Bi or Te/Bi2Te3 nucleocapsid heterojunction structure nanometer wire and method for preparing same

A nanowire and heterojunction technology, applied in the field of thermoelectric materials and its preparation, to achieve the effect of complicated operation and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1: Synthesis of Te / Bi core-shell heterostructure nanowires

[0035] 1) Synthesis of single crystal Te nanowires

[0036] 0.6 g polyvinylpyrrolidone (PVP) 0.48 g TeO 2 Disperse the powder in 50 ml of ethylene glycol, heat until the solution is clear, transfer the prepared solution to a three-necked flask with a capacity of 250 ml, and increase the temperature to 150 degrees Celsius; add 0.5-1 ml of hydrazine hydrate at this temperature, Te nanowire colloidal solution (named as intermediate product 1) can be obtained after reacting for 20 minutes at 100°C; after natural cooling, the reaction product solution is taken out, the product is separated by centrifugation, and the product is washed with distilled water and absolute ethanol for 3 times, Te nanowire samples were obtained.

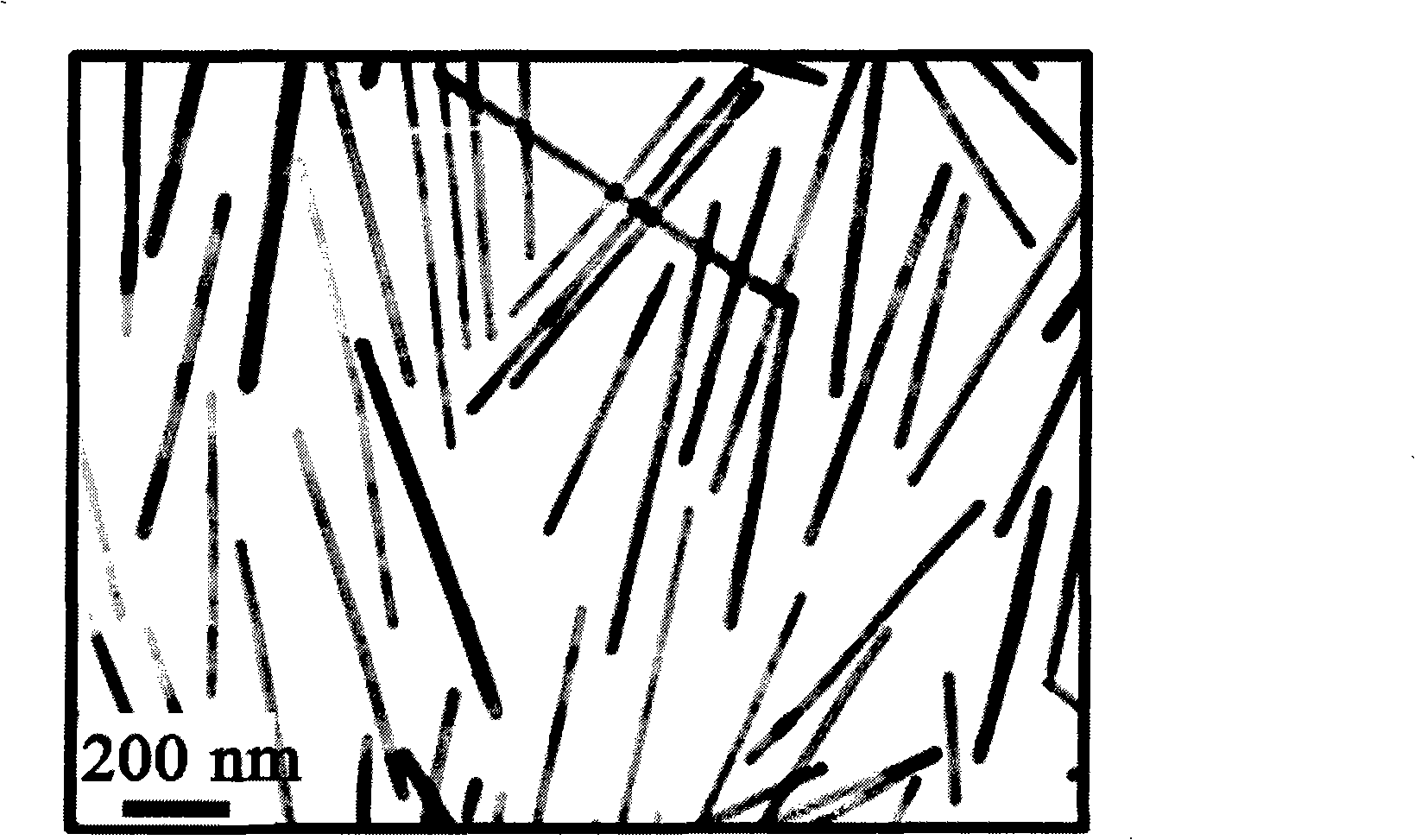

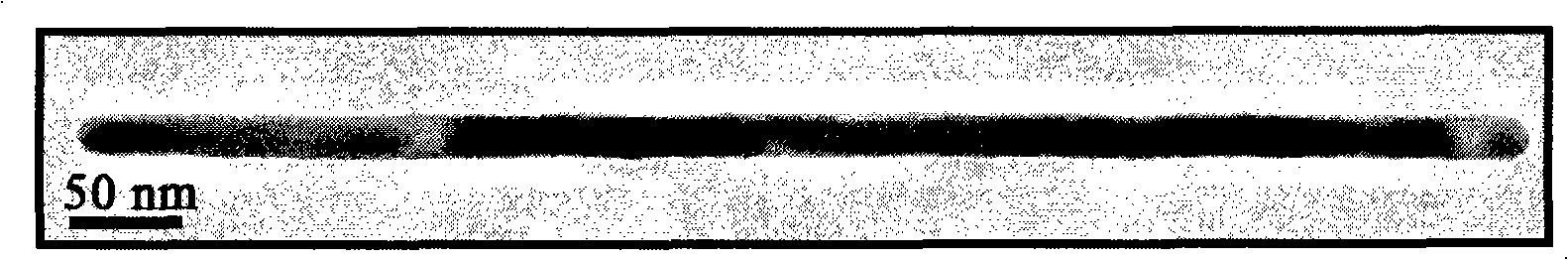

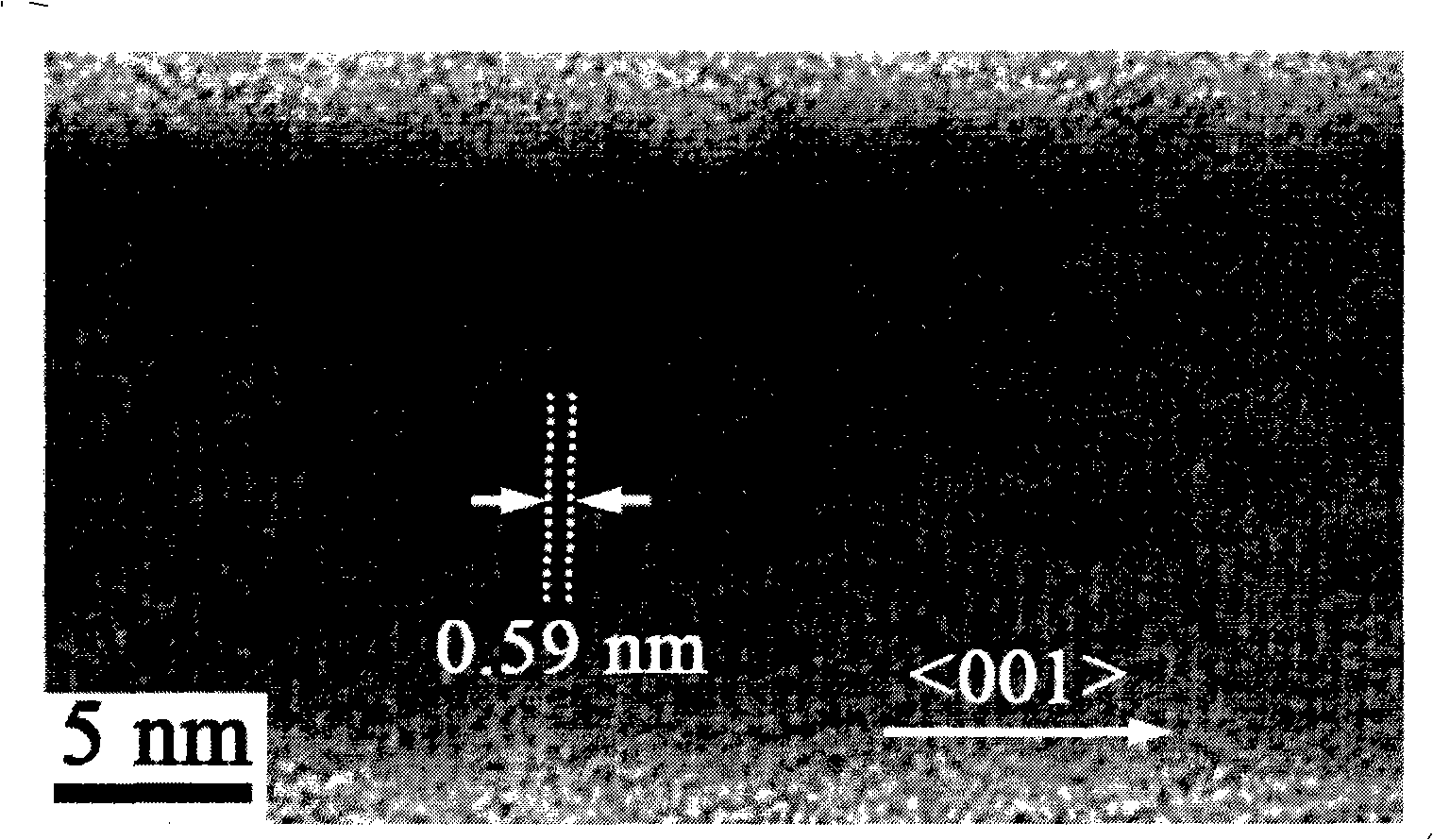

[0037] The morphology and microstructure of the samples were observed by Hitachi H-800 transmission electron microscope (TEM) and JEOL-2010 high-resolution transmission electron micros...

Embodiment 2

[0050] Example 2: Te / Bi 2 Te 3 Synthesis of Core-Shell Heterostructure Nanowires

[0051] 1) Synthesis of elemental Te single crystal nanowires

[0052] The preparation method is the same as Step 1 in Example 1. The difference is that the TeO added in this example 2 The amount of the powder was 0.2394 g; the obtained Te nanowire solution was named as the intermediate product 1 of Example 2.

[0053] 2) Te / Bi 2 Te 3 Synthesis of Core-Shell Heterostructure Nanowires

[0054] 0.3 g of PVP, 0.485 g of Bi(NO 3 ) 3 ·5H 2 O powder, 0.135 g H 2 C 2 o 4 powder and 0.2394 g TeO 2 Disperse the powder in 25 ml of ethylene glycol, stir until a uniform white milky turbid solution is formed, named Bi-Te precursor solution; after ultrasonically dispersing the white milky turbid solution for 10-20 minutes, pour it into the solution at 150 degrees Celsius In Example 2, the intermediate product 1 was incubated for 40 minutes to obtain Te / Bi 2 Te 3 The colloidal solution of the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com