Technological process for dying light antique bronze color on surface of brass products

A bronze color and device surface technology, which is applied in special art surface treatment, metal material coating technology, decorative art, etc., can solve the problems of highly toxic reagents or complex processes, long dyeing time, etc., to achieve easy mastery and operation, process Simple, Inexpensive Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The technological process and steps of the present embodiment are as follows:

[0022] 1. Prepare light bronze staining solution (1): mix 10g KMnO 4 or K 2 S 2 o 8 or NH 4 S 2 o 8 Dissolve one of them in 200ml of water, then add 20g of CuSO to the solution 4 ·5H 2 O or CuCl 2 , and stir evenly to form a mixed solution.

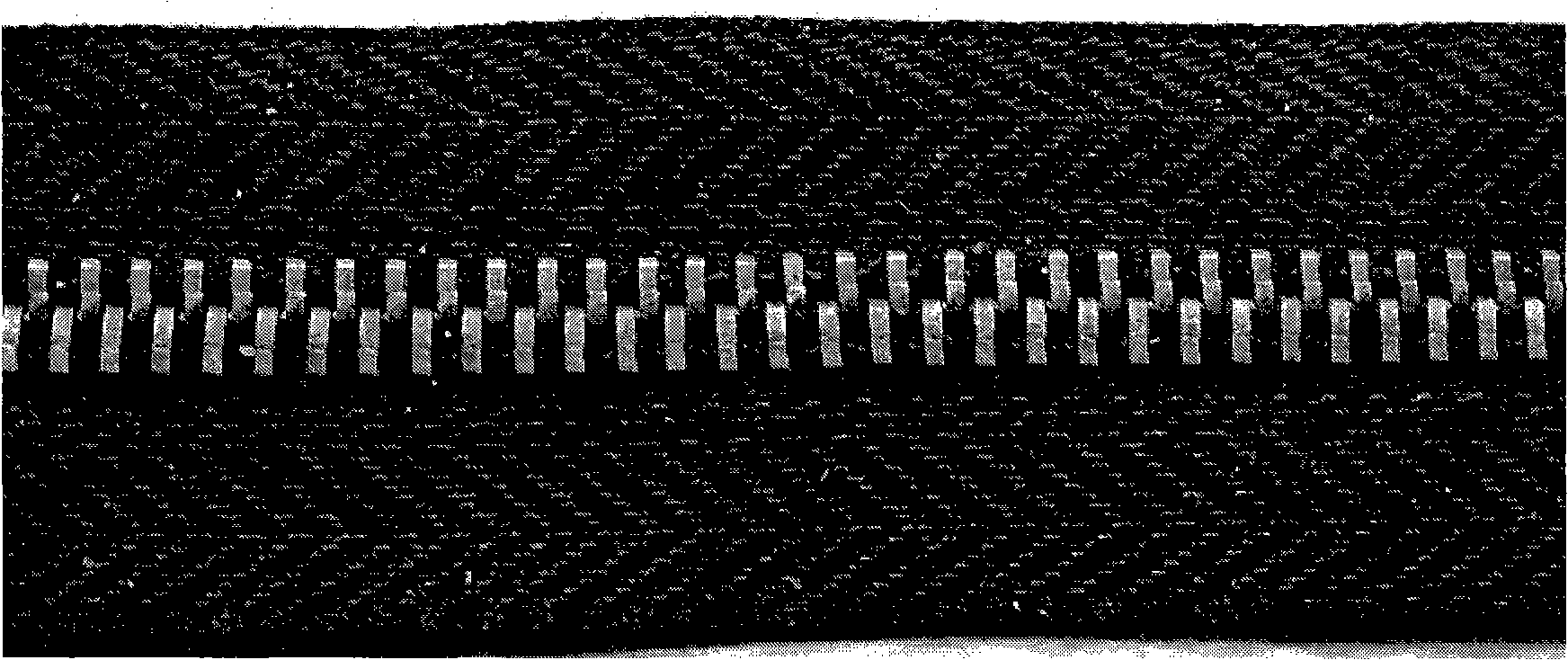

[0023] 2. Cut 10cm off the brass zipper, soak it in 5% NaOH solution at 70 degrees Celsius for 10 minutes to remove oil, then wash it with water and dry it.

[0024] 3. Put the brass zipper that has been degreased and clean into the above-mentioned light bronze staining solution (1) at 80 degrees Celsius, and dye it for 5 minutes, then take it out, wash and dry.

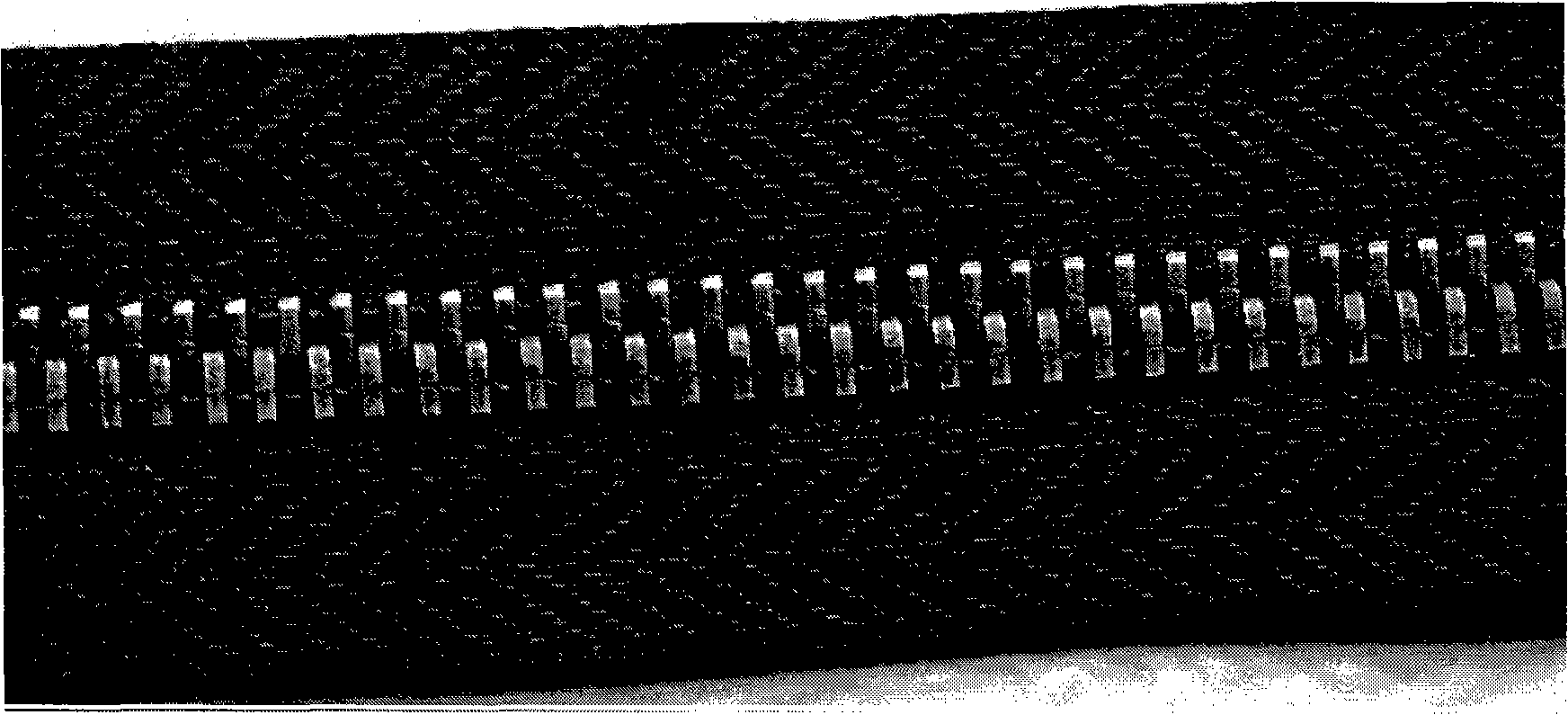

[0025] 4. Use a cloth wheel polisher to polish with a small amount of paraffin wax, and finally get a light bronze-colored brass zipper with uniform surface color and strong combination of color layers.

Embodiment 2

[0027] The technological process and steps of the present embodiment are as follows:

[0028] 1. Prepare light bronze staining solution (2): mix 5gKMnO 4 and 5gK 2 S 2 o 8 Dissolve in 200ml water, then add 20g CuSO to the solution 4 ·5H 2 O or CuCl 2 , and stir evenly to form a mixed solution.

[0029] 2. Cut 10cm off the brass zipper, soak it in 5% NaOH solution at 70 degrees Celsius for 10 minutes to remove oil, then wash it with water and dry it.

[0030] 3. Put the brass zipper that has been degreased and clean into the above-mentioned light bronze dyeing solution (2) at 80 degrees Celsius, and dye it for 15 minutes, then take it out, wash and dry.

[0031] 4. Use a cloth wheel polisher to polish with a small amount of paraffin wax, and finally get a light bronze-colored brass zipper with uniform surface color and strong combination of color layers.

Embodiment 3

[0033] The technological process and steps of the present embodiment are as follows:

[0034] 1. Prepare light bronze staining solution (3): mix 5gKMnO 4 and 5gNH 4 S 2 o 8 Dissolve in 200ml water, then add 20g CuSO to the solution 4 ·5H 2 O or CuCl 2 , and stir evenly to form a mixed solution.

[0035] 2. Cut 10cm off the brass zipper, soak it in 5% NaOH solution at 70 degrees Celsius for 10 minutes to remove oil, then wash it with water and dry it.

[0036] 3. Put the brass zipper that has been degreased and clean into the above-mentioned light bronze staining solution (3) at 80 degrees Celsius, and dye it for 15 minutes, then take it out, wash and dry.

[0037] 4. Use a cloth wheel polisher to polish with a small amount of paraffin wax, and finally get a light bronze-colored brass zipper with uniform surface color and strong combination of color layers.

[0038] The color and appearance of the brass zipper dyeing product obtained in the above-mentioned examples are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com