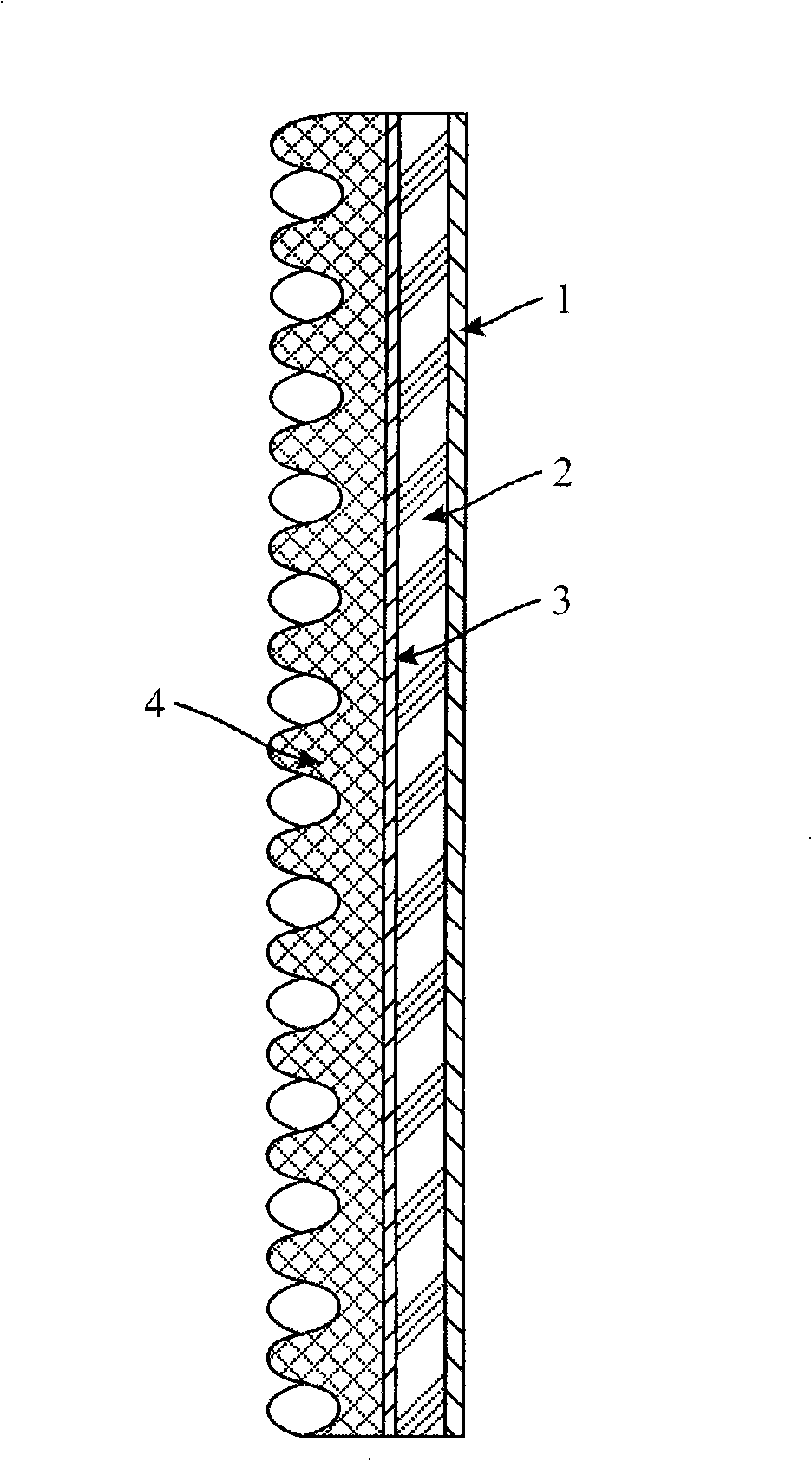

Multifunctional composite sheet material and process for making same

A production process, multi-functional technology, applied in the direction of flat products, other household appliances, synthetic resin layered products, etc., can solve the problem of affecting the normal flow and operation of oil and gas in the pipe, accelerate the degree of photoaging and thermal aging of the pipe network, shorten the The service life of pipe network and other equipment can reduce the photoaging and thermal aging process, facilitate maintenance and operation, and prevent water flow from freezing and freezing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] The manufacturing process of the composite multifunctional sheet, the steps are as follows,

[0062] ①. Raw material preparation: prepare raw materials according to the following raw materials and parts by weight, wherein,

[0063] PVC resin 90

[0064] Powdered Nitrile Rubber 10

[0066] carbon black 5

[0067] Diatomaceous earth 60

[0068] Dioctyl phthalate 40

[0069] Stearic acid 5

[0072] Azodicarbonamide 3

[0073] Antioxidant 264 3;

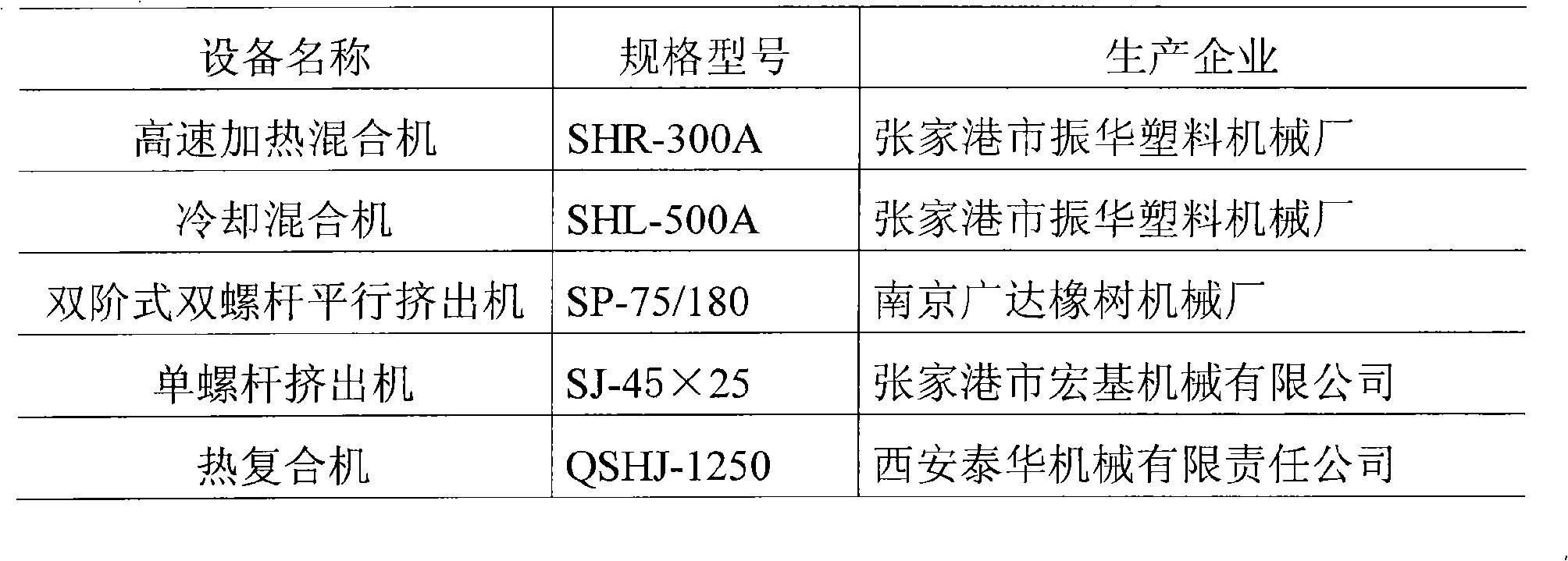

[0074] ②. Thermal mixing: Put the polyvinyl chloride resin, powdered nitrile rubber, barium sulfate, carbon black, and diatomaceous earth among the above raw materials into a high-speed heating mixer with a volume of 300L for high-speed mixing, so that the temperature reaches 60±5 ℃, then add stearic acid, zinc stearate, calcium stearate, antioxidant 264 and continue mixing at high speed, and when the temperature reaches 70℃, slowly add dioct...

Embodiment 2

[0081] The manufacturing process of the composite multifunctional sheet, the steps are as follows,

[0082] ①. Raw material preparation: prepare raw materials according to the following raw materials and parts by weight, wherein,

[0083] PVC resin 80

[0084] Powdered Nitrile Rubber 20

[0086] carbon black 3

[0087] Diatomaceous earth 40

[0088] Dioctyl phthalate 30

[0089] stearic acid 2

[0090] Zinc stearate 2

[0092] Azodicarbonamide 1

[0093] Antioxidant 264 0.5;

[0094] ②. Thermal mixing: Put the polyvinyl chloride resin, powdered nitrile rubber, barium sulfate, carbon black, and diatomaceous earth among the above raw materials into a high-speed heating mixer with a volume of 300L for high-speed mixing, so that the temperature reaches 60±5 ℃, then add stearic acid, zinc stearate, calcium stearate, antioxidant 264 and continue mixing at high speed, and when the temperature reaches 70℃, slowly add dio...

Embodiment 3

[0101] The manufacturing process of the composite multifunctional sheet, the steps are as follows,

[0102] ①. Raw material preparation: prepare raw materials according to the following raw materials and parts by weight, wherein,

[0103] PVC resin 85

[0104] Powdered Nitrile Rubber 15

[0105] Barium sulfate 50

[0106] carbon black 4

[0107] Diatomaceous earth 50

[0108] Dioctyl phthalate 35

[0109] stearic acid 3

[0110] Zinc stearate 3

[0112] Azodicarbonamide 2

[0113] Antioxidant 264 1.5;

[0114] ②. Thermal mixing: Put the polyvinyl chloride resin, powdered nitrile rubber, barium sulfate, carbon black, and diatomaceous earth among the above raw materials into a high-speed heating mixer with a volume of 300L for high-speed mixing, so that the temperature reaches 60±5 ℃, then add stearic acid, zinc stearate, calcium stearate, antioxidant 264 and continue mixing at high speed, and when the temperature reaches 70℃, slowly add dio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com