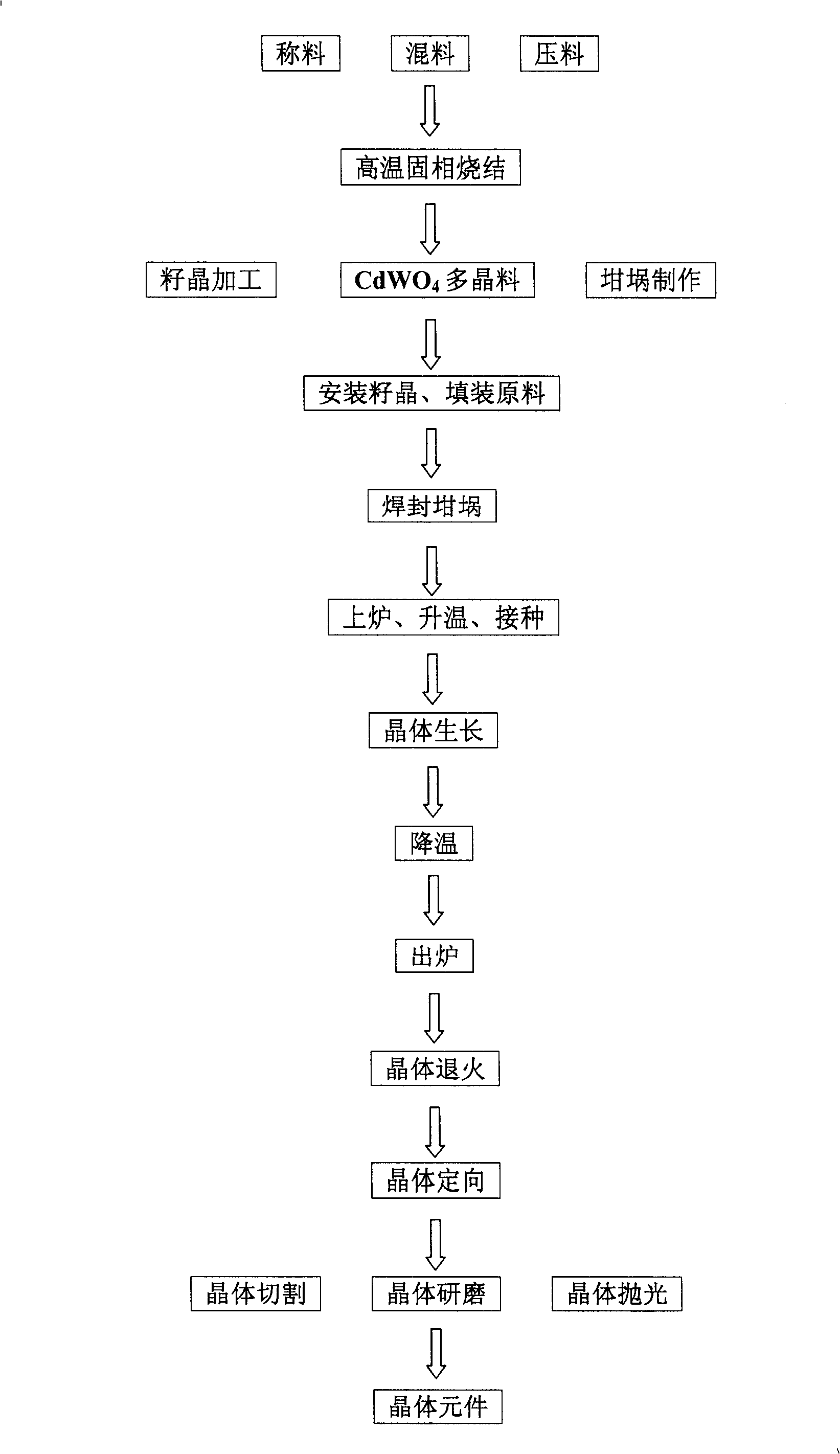

Growth technique for cadmium tungstate twinkling monocrystal with crucible descent method

A crucible descending method, cadmium tungstate technology, applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve the problems of environmental pollution, chronic cadmium poisoning of operators, large thermal stress, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the present invention enumerate as follows:

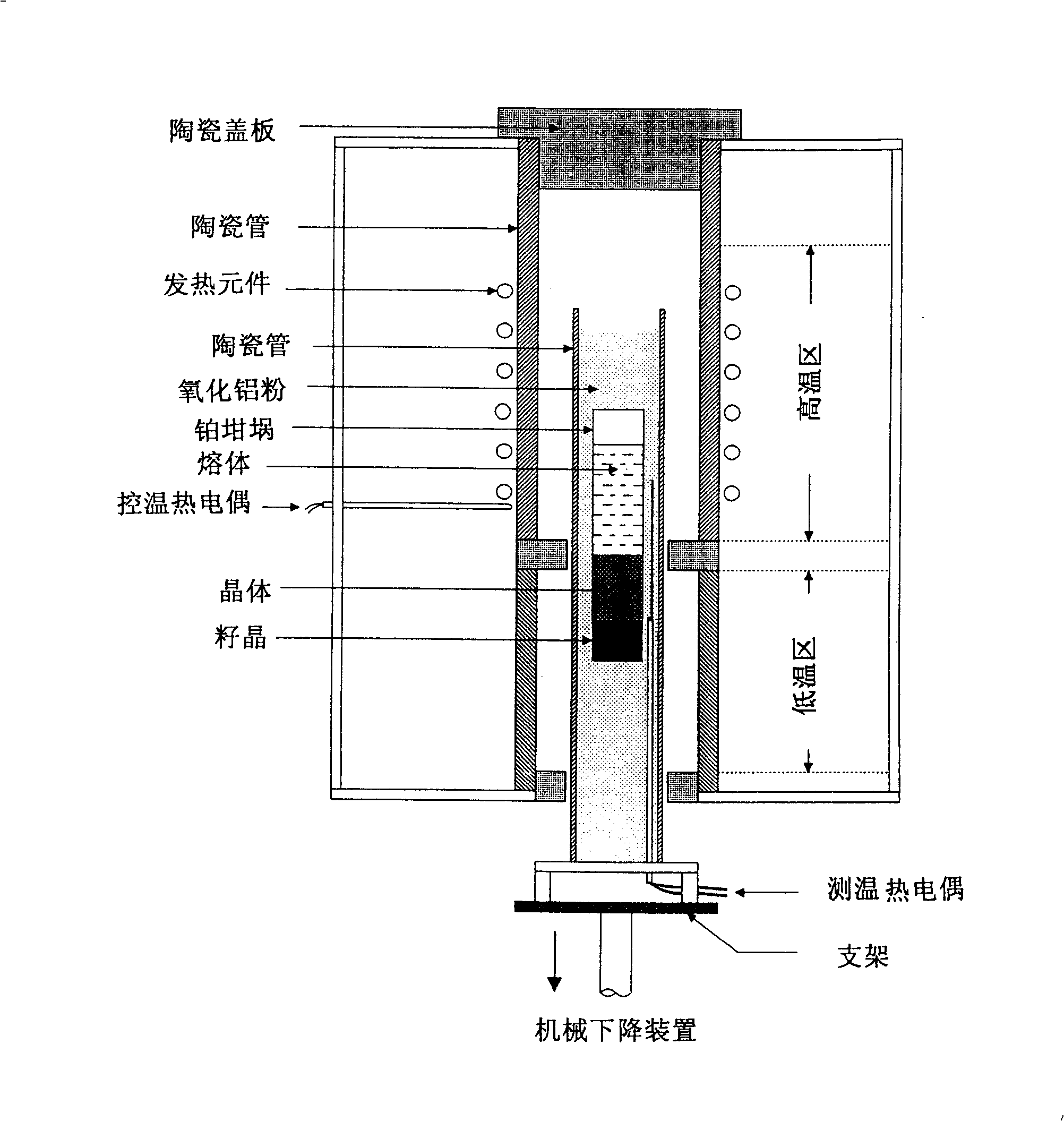

[0021] (1) Use platinum foil with a wall thickness of 0.18mm to process a cylindrical crucible, and its lower volume is Ф25×80mm 3 , the upper volume is Ф50×240mm 3 , with a funnel-shaped center. Orient , size Ф24.5×50mm 3 The seed crystal is installed in the lower part of the crucible, and then the polycrystalline material is filled into the upper part of the seed crystal, and then the two ends of the crucible are welded. During the crystal growth process, the crystal growth furnace is controlled at 1370-1380°C, and the crucible is first adjusted to an appropriate position to melt the raw material and the top of the seed crystal to form a stable solid-liquid interface with a temperature gradient of 30°C / cm. After 4 hours of heat preservation , making the crucible drop at a speed of 0.8 mm / hour. After the crystal growth process is over, the furnace temperature is lowered to room temperature at a rate of 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com