Preparation method for 110ksi high grade steel and high CO2-corrosion resistant tubing and casing and the tubing and casing

A technology of oil casing and steel grade, which is applied in the field of oil casing to achieve the effects of reducing alloy cost, increasing tempering temperature, improving steel growth rate and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

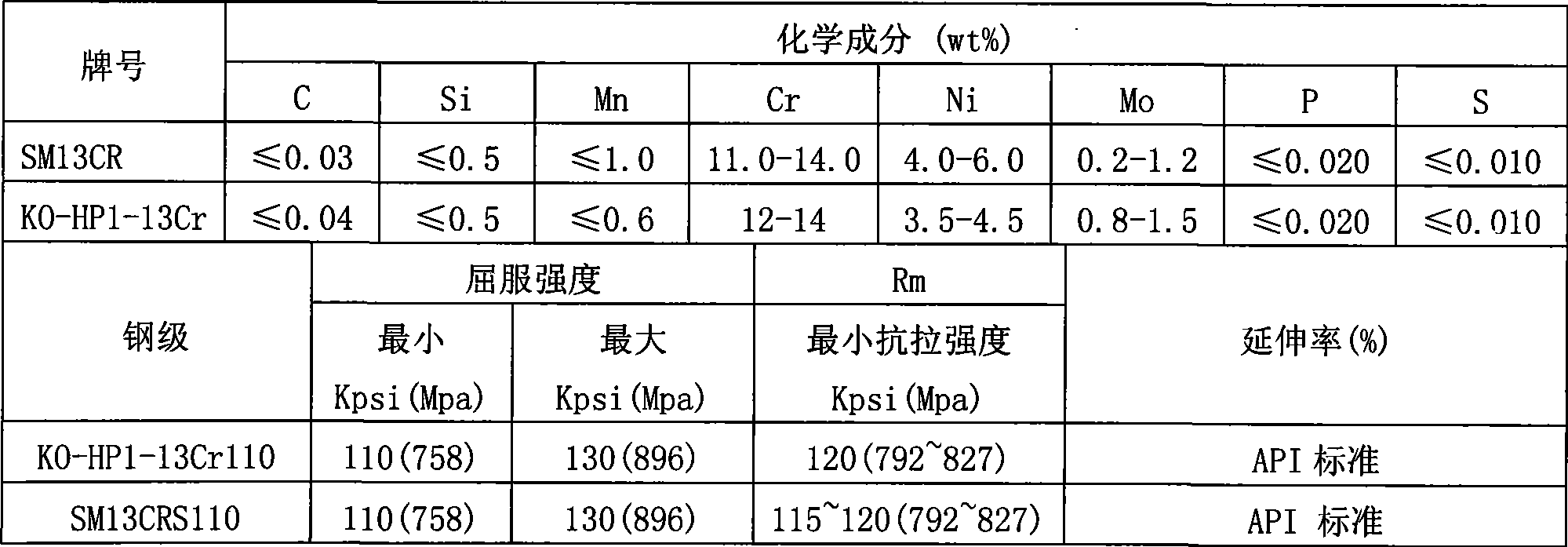

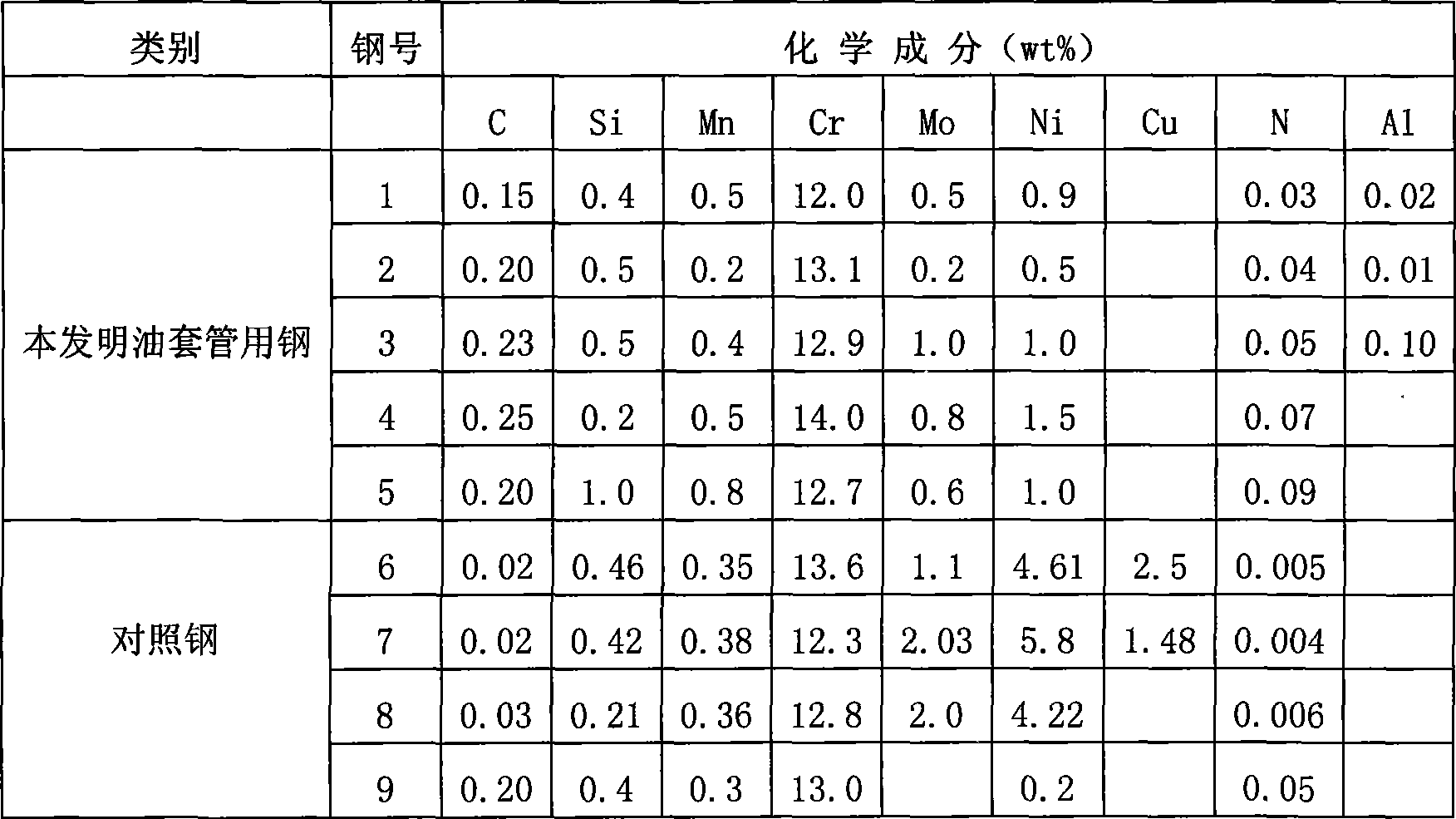

[0059] Table 3 has listed the 110ksi high steel grade of the present invention, high anti-CO 2 The chemical composition of 5 kinds of 13Cr steel grades 1 to 5 and control steels 6 to 9 (oil casing alloys commonly used in oilfields) for corroding oil and casing.

[0060] Table 3 The chemical composition (wt%) of steel for oil casing of the present invention and existing oil casing alloy

[0061]

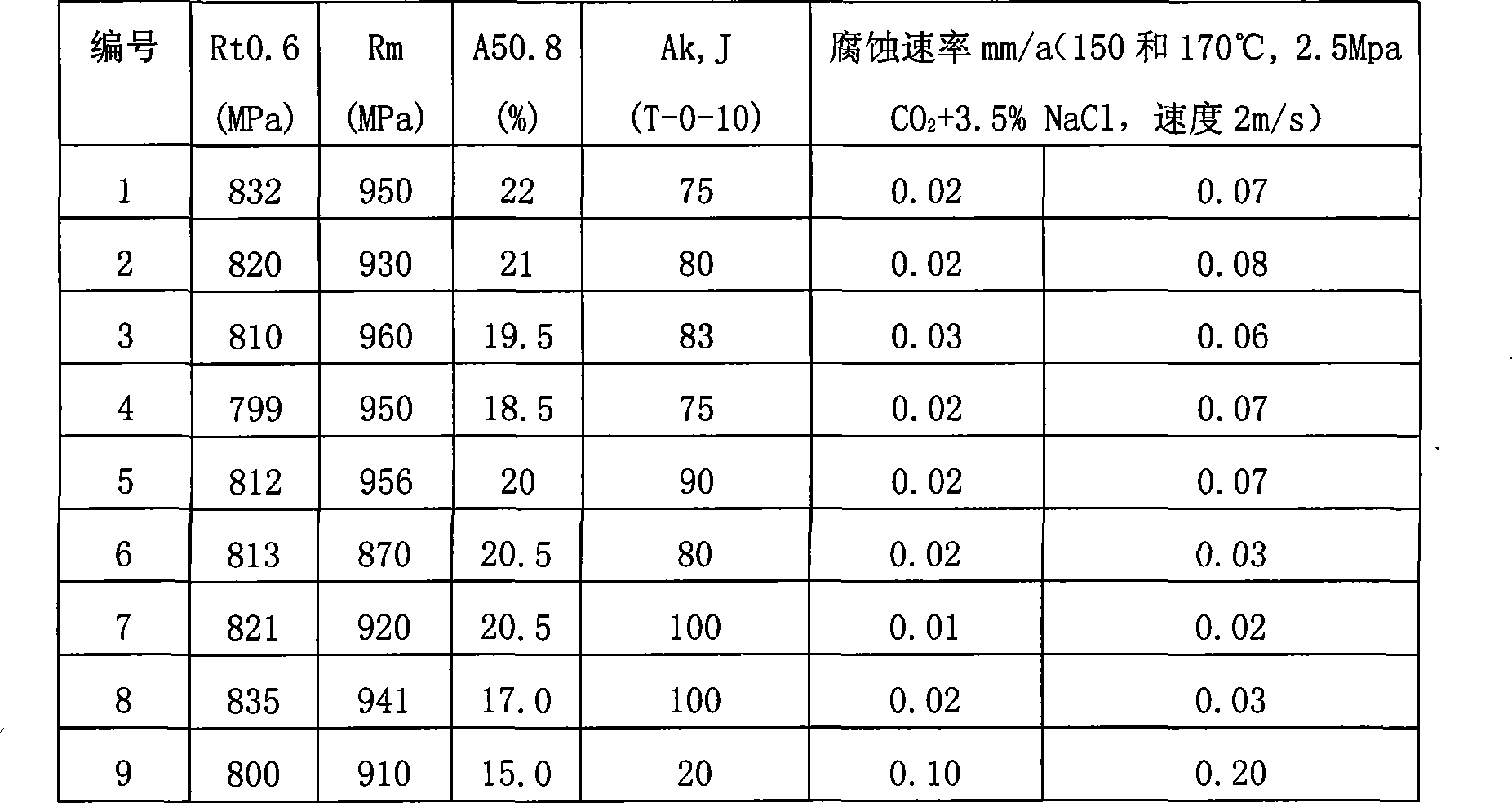

[0062] According to the chemical composition shown in Table 3, the steel grades of steel grades 1-5 are smelted in the converter, and the molten steel after smelting is cast into ingots. The rough round billet is annealed after rolling, and the annealing temperature is controlled between 650-750°C. After the annealed tube is heated at 1150-1200°C for 1.5-2 hours, it is pierced and hot-rolled into a blank tube. The steel pipe is then quenched at 900-980° C. and tempered at 580-660° C., and the tempering time is controlled within 1 hour, so as to obtain the 110 steel grade oil casin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com