A composite heat treatment process for wear-resistant gears

A composite heat treatment and process technology, applied in heat treatment furnaces, heat treatment equipment, metal material coating processes, etc., can solve the problems of complex heat treatment process and insignificant energy saving effect, and achieve the effect of improving hardness, saving energy and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

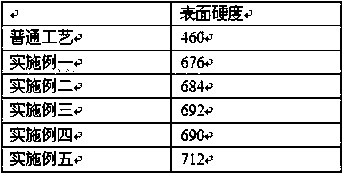

Examples

Embodiment 1

[0017] The invention provides a technical solution: a composite heat treatment process for wear-resistant gears, comprising the following steps:

[0018] A. Cleaning and drying: send the workpiece to the washing machine for drying, the drying time is 45min, and then send the dried workpiece to the heating chamber;

[0019] B. Carburizing: Heat up the heating chamber. During the heating process, the amount of propane is 0.15L / h. When the temperature of the heating chamber rises to 880°C, the amount of propane is 0.25L / h, and the standard air is 20L / h. Maintain a constant temperature for 10 minutes; then heat the radiant tube in the heating chamber with full power, the temperature rises to 925°C, the amount of propane introduced is 0.15L / h, the standard air is 20L / h, and the carbon potential is 1.2; then diffuse , the diffusion temperature is 925°C, the carbon potential drop is 0.85; then the temperature is lowered to 820°C, the holding time is 20min, and the carbon potential re...

Embodiment 2

[0028] The invention provides a technical solution: a composite heat treatment process for wear-resistant gears, comprising the following steps:

[0029] A. Cleaning and drying: send the workpiece to the washing machine for drying, the drying time is 45min, and then send the dried workpiece to the heating chamber;

[0030] B. Carburizing: Raise the temperature of the heating chamber. During the heating process, the amount of propane introduced is 0.15L / h. Maintain a constant temperature for 10 minutes; then heat the radiant tube in the heating chamber with full power, the temperature rises to 925°C, the amount of propane introduced is 0.15L / h, the standard air is 20L / h, and the carbon potential is 1.3; then diffuse , the diffusion temperature is 925°C, the carbon potential drop is 0.85; then the temperature is lowered to 830°C, the holding time is 25min, and the carbon potential remains at 0.85;

[0031] C. Protective gas air cooling: After the program is finished, the PPC se...

Embodiment 3

[0039] The invention provides a technical solution: a composite heat treatment process for wear-resistant gears, comprising the following steps:

[0040] A. Cleaning and drying: send the workpiece to the washing machine for drying, the drying time is 45min, and then send the dried workpiece to the heating chamber;

[0041] B. Carburizing: Raise the temperature of the heating chamber. During the heating process, the amount of propane is 0.15L / h. Maintain a constant temperature for 10 minutes; then heat the radiant tube in the heating chamber with full power, the temperature rises to 915°C, the amount of propane introduced is 0.15L / h, the standard air is 20L / h, and the carbon potential is 1.3; then diffuse , the diffusion temperature is 915°C, the carbon potential drop is 0.90; then the temperature is lowered to 820°C, the holding time is 25min, and the carbon potential remains at 0.90;

[0042] C. Protective gas air cooling: After the program is finished, the PPC sends the wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com