Heat-resistant light-shading film and production method thereof, and diaphragm or light intensity adjusting device using the same

A manufacturing method and technology of light-shielding sheets, which are applied in the fields of sliding and low gloss, can solve problems such as inability to play, poor thermal stress, and increased irregular friction, and achieve excellent friction resistance, excellent heat resistance, Excellent productivity

Inactive Publication Date: 2008-10-15

SUMITOMO METAL MINING CO LTD

View PDF8 Cites 14 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In such a harsh environment, if the above-mentioned conventional light-shielding sheet is used, deformation, discoloration, etc. will occur, and it is not preferable in terms of durability, and there are problems in practical use.

In addition, since the shading sheet is thermally deformed in a high-temperature environment above 155°C, even the shading sheet with a fine uneven structure on the above-mentioned surface has a large thermal deformation, and the shading sheets are in contact with each other, making it impossible to move at a high speed and not The degree of regular friction increases, leading to deterioration of slipperiness and glossiness, etc., and there is a possibility that digital cameras, digital video cameras, and liquid crystal projectors cannot perform their original functions.

In addition, although the above-mentioned roughening treatment of the base plastic film has the effect of improving the adhesion between the base material and the coating film on the base material and reducing the surface gloss by forming fine unevenness on the base plastic film However, when using the sandblasting method, since the roughness of the sheet surface depends on the material, particle size, spray pressure, etc. of the blasting material, although the blasting material with a large particle size can be removed from the sheet surface by washing with water or brushing, the particles Small particles with a diameter of less than 1 μm will remain on the sheet even after washing, and cannot be completely removed

If the sprayed material remains, in the high temperature environment where the light-shielding sheet is located, due to the difference in thermal expansion coefficient between the sprayed material and the film such as the metal alloy light-shielding film formed on the sheet, there will be a difference in thermal stress and the film will be detached, and the sprayed material will be detached from the sheet. Down, it will adversely affect its surrounding components, resulting in the problem of not being able to perform its original function

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

| Heat resistance | aaaaa | aaaaa |

Login to View More

Abstract

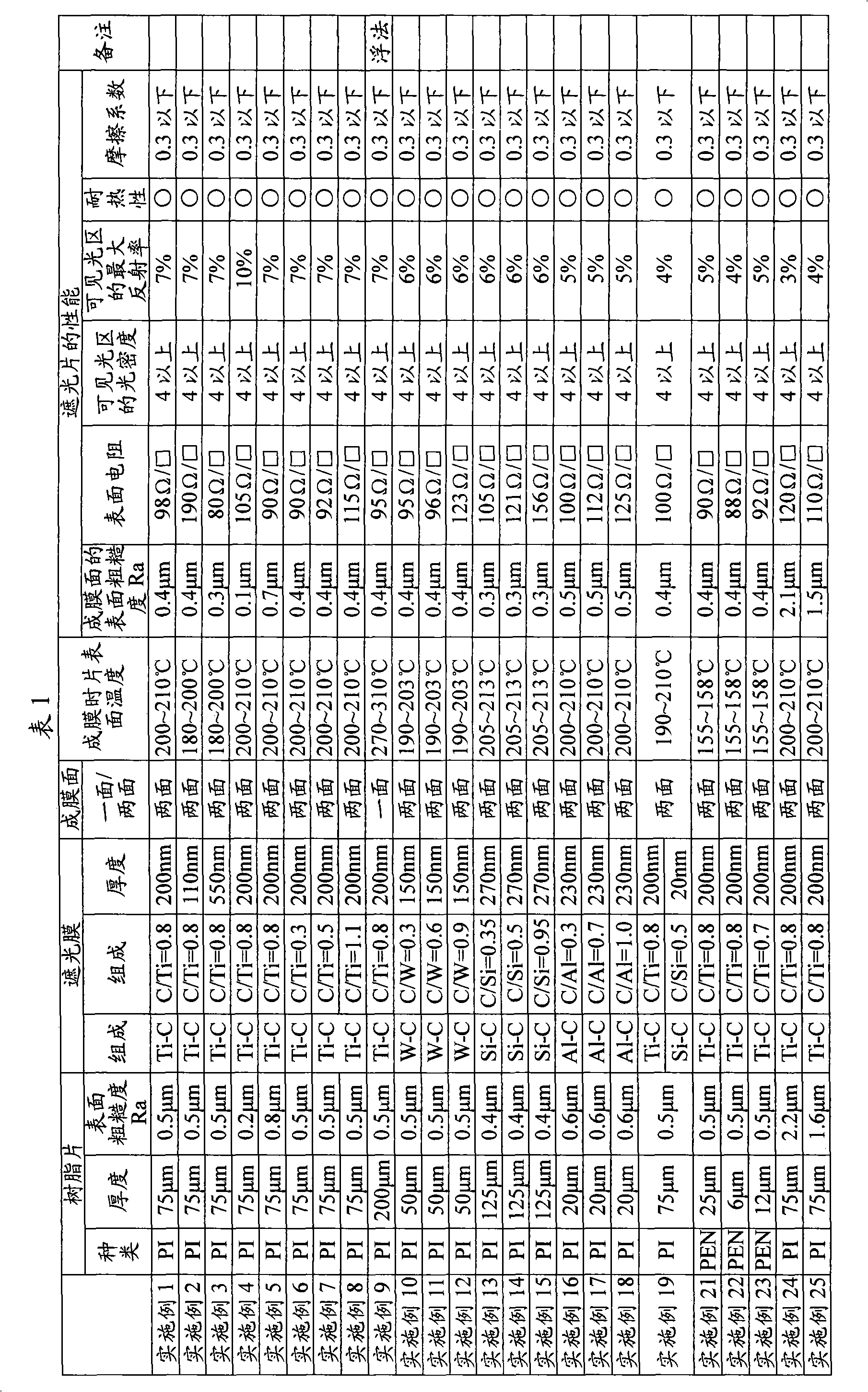

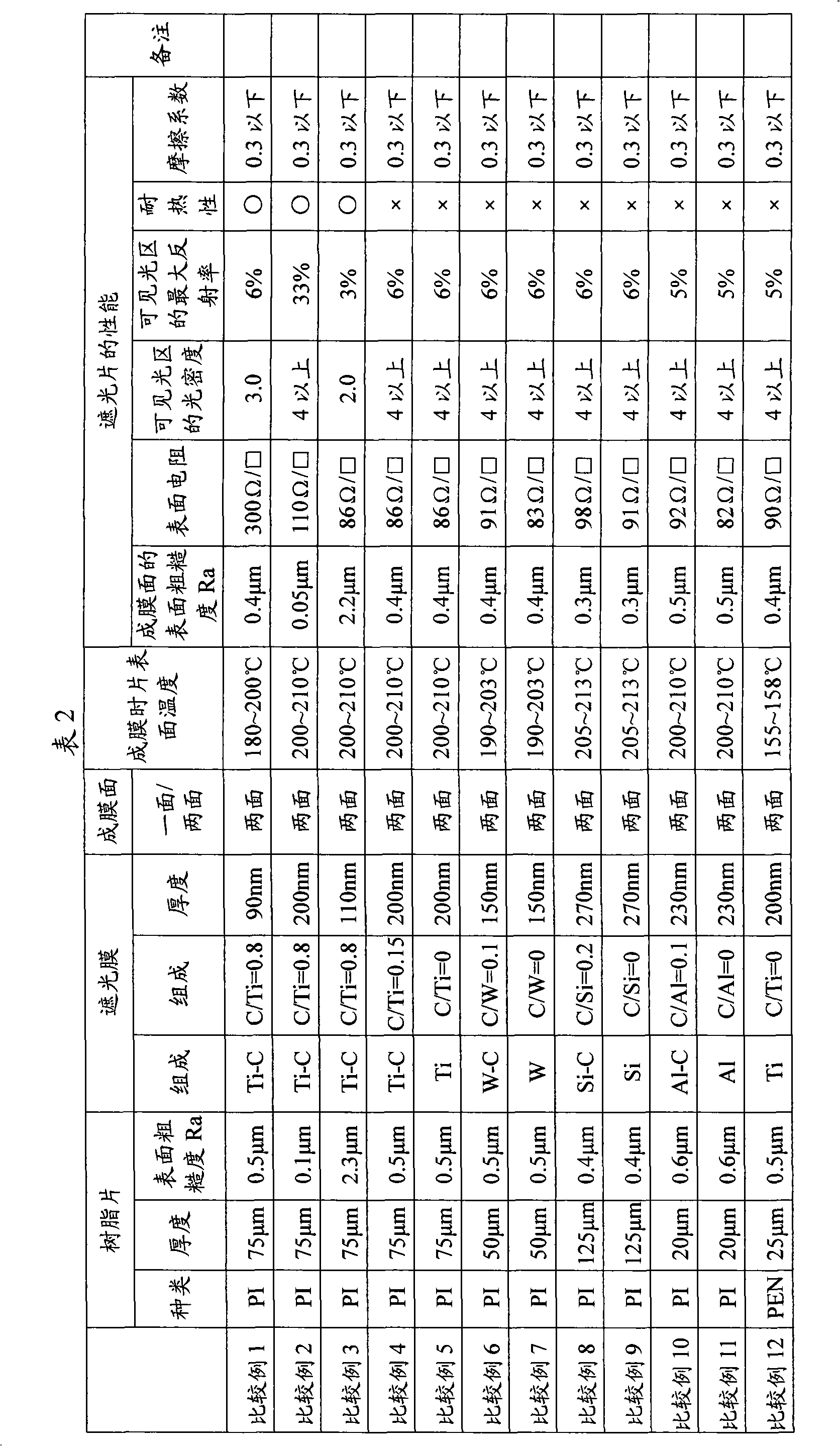

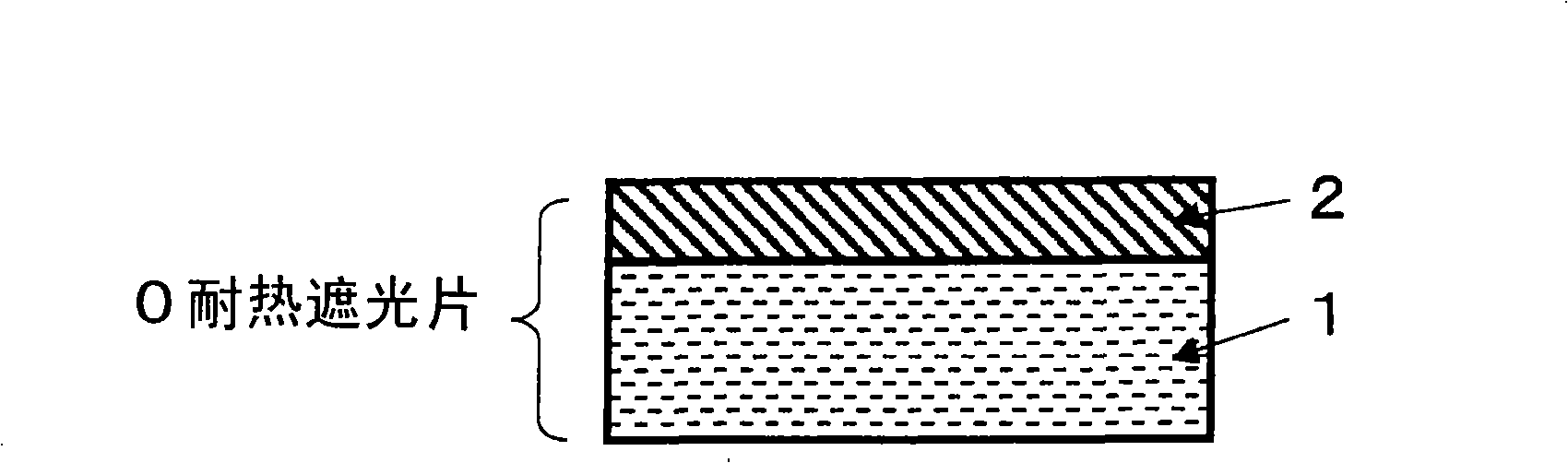

A heat-resistant light-shading film having high light shading capacity, high heat resistance, high sliding characteristics, low surface gloss and high electroconductivity, and useful for optical device parts such as shutter blades or diaphragm blades for diaphragm blades of lens shutter and the like for digital cameras and digital video cameras and diaphragm blades of light intensity adjusting device for projectors, and a method for producing the same.; The heat-resistant light-shading film is a film comprising a resin film substrate (A) having a heat resistance of 155 DEG C. or higher and a light-shading layer (B) of crystalline metal carbide film (MeC) formed on one side or both sides of the resin film substrate (A), characterized in that the light-shading layer (B) has a thickness of 100 nm or more and a surface roughness of 0.1 to 2.1 mum (arithmetic average height Ra), and content of carbon element (C) in the metal carbide film (MeC) is 0.3 or more in atomic number ratio to the total metal elements (Me).

Description

Heat-resistant light-shielding sheet, manufacturing method thereof, and aperture or light amount adjusting device using same technical field The present invention relates to a heat-resistant light-shielding sheet, a manufacturing method thereof, and a diaphragm or a light amount adjusting device using the same, and more particularly, to shutter blades or diaphragm blades as lens shutters of digital cameras and digital video cameras, and lens units for vehicle-mounted monitors A heat-resistant light-shielding sheet excellent in light-shielding properties, heat resistance, sliding properties, low gloss, and electrical conductivity, and its manufacturing method, as well as the use of optical instrument parts such as the fixed aperture or the aperture blade of the light amount adjustment device of a projector Aperture or light adjustment device. Background technique Currently, shutter blades and diaphragm blades for cameras are required to be lightweight and have high sliding ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G02B5/00G03B9/02G02B26/02

CPCC23C14/205G02B1/10G02B5/003G02B5/021G03B9/06

Inventor 阿部能之小野胜史冢越幸夫

Owner SUMITOMO METAL MINING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com