Method for preparing sheet silver powder with high dispersibility

The technology of flake silver powder and high dispersibility is applied to the preparation of high dispersity flake silver powder for electromagnetic shielding coatings and the field of conductive coatings, and can solve the problems of poor stability, difficult control, and unsatisfactory flake silver performance. Achieve the effect of high flatness, simple and feasible process flow, stable and reliable process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

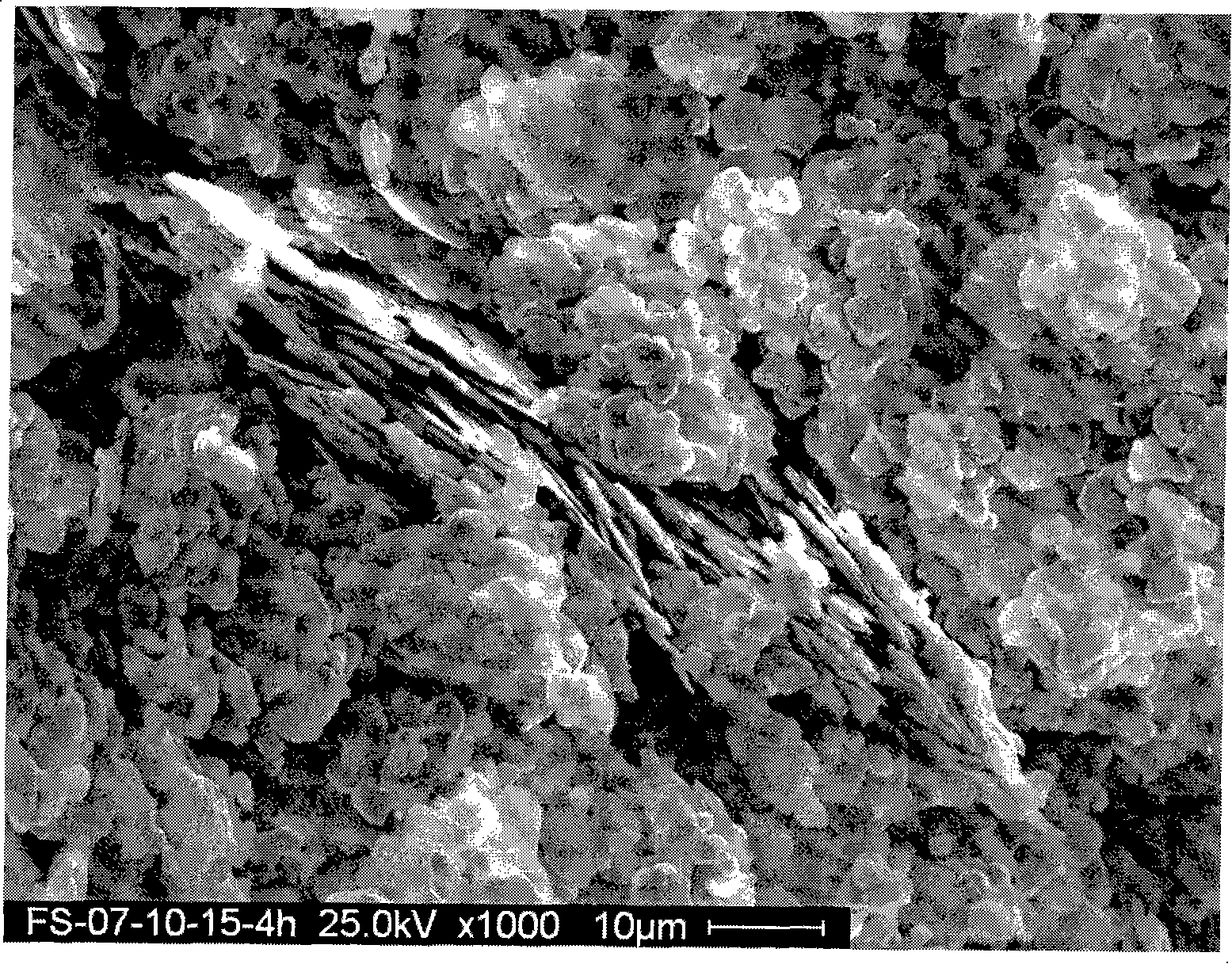

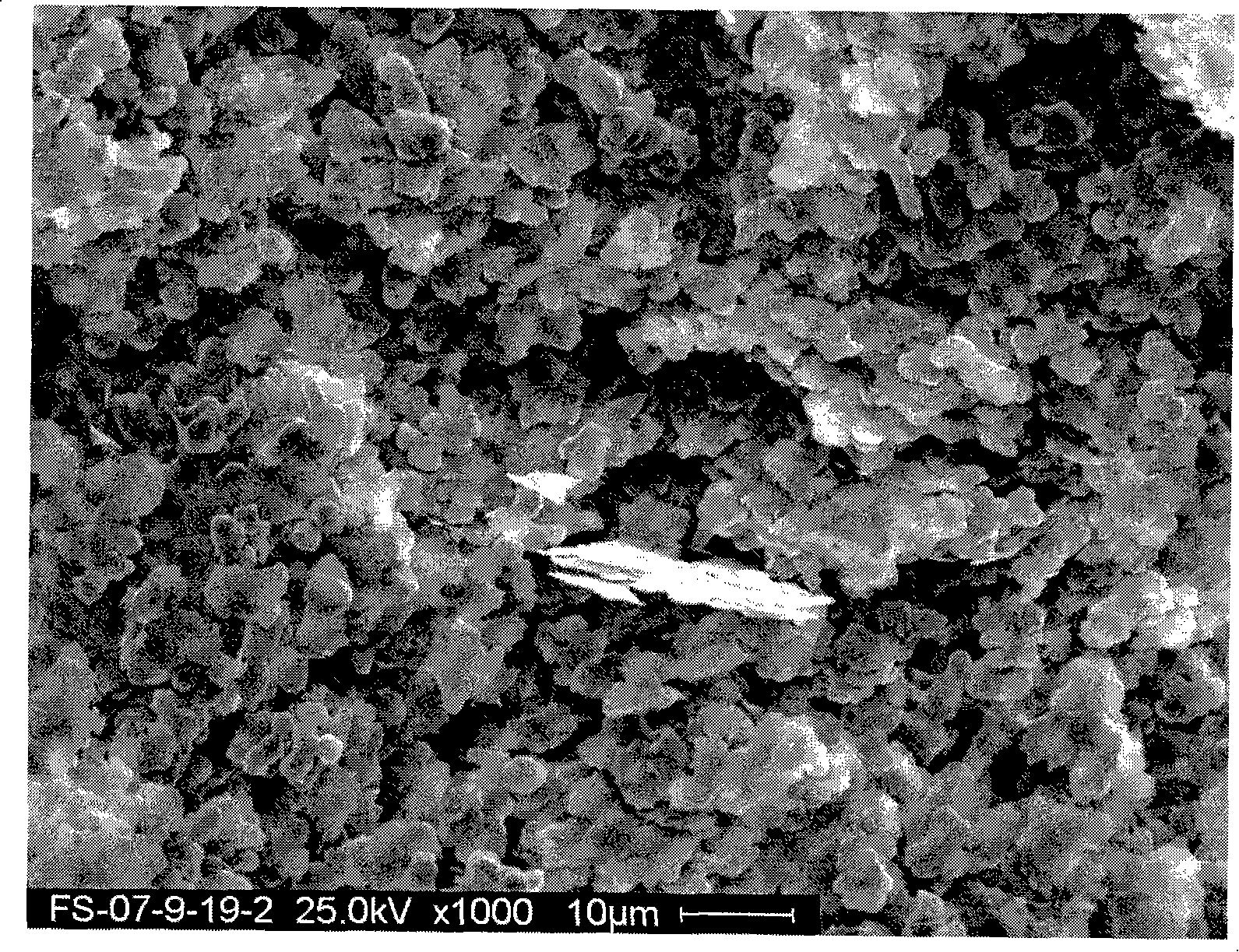

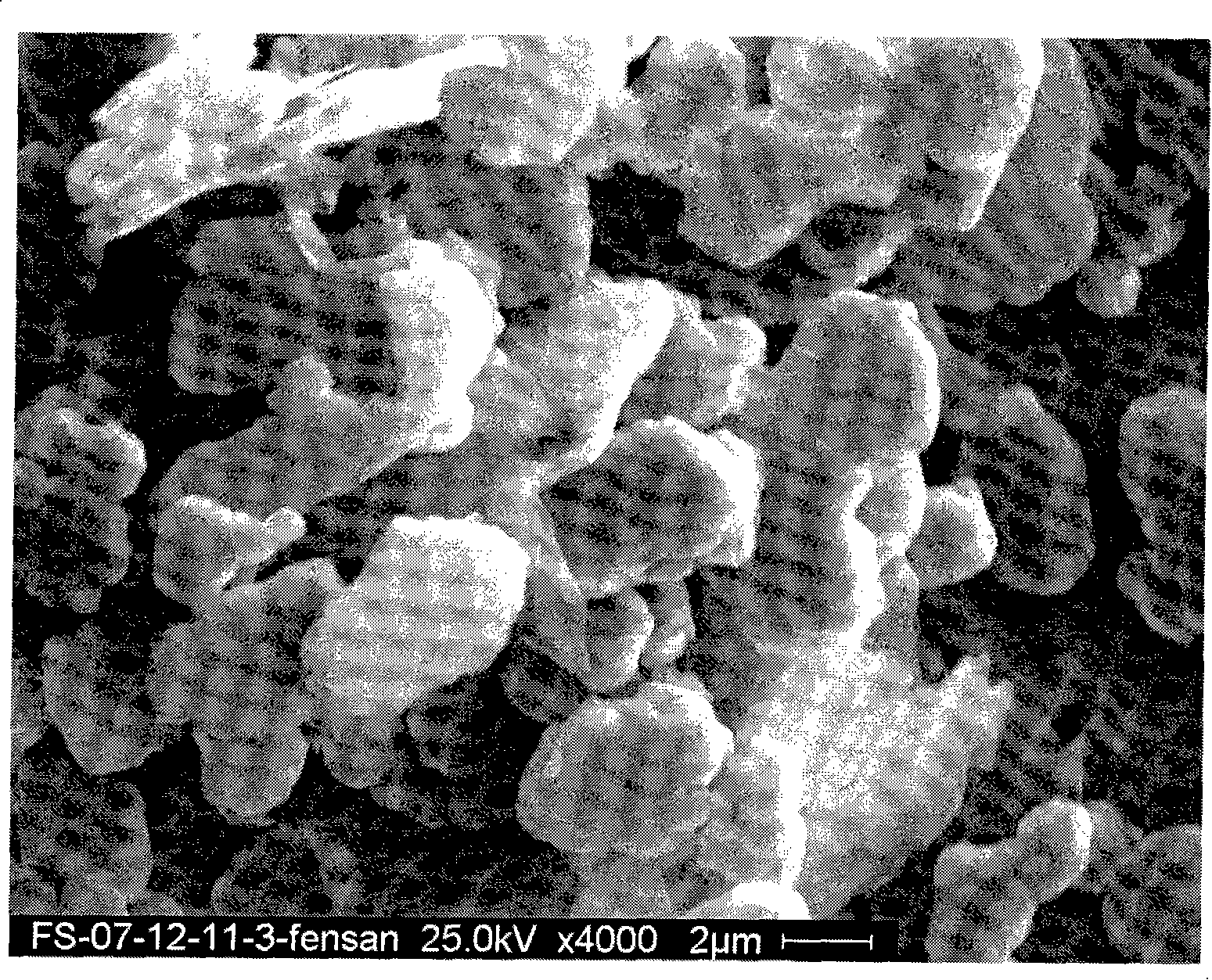

[0021] The preparation method of highly dispersible flaky silver powder adopts the particle size D prepared by liquid phase reduction method. 50 Spherical raw material silver powder with a thickness of 1-3μm and a silver content >99.95% is ground into flake powder of required specifications by vertical stirring ball milling process or planetary ball milling process, and then its dispersion is improved by post-processing such as ultrasonic dispersion and air flow dispersion properties, the prepared film diameter D 50 3~25μm, bulk density 0.5~1.8g / cm 3 Highly dispersed flaky silver powder.

[0022] The two ball milling processes are as follows:

[0023] 1) Vertical stirring ball mill: Add 1 / 3 to 2 / 3 zirconia grinding balls of the volume of the ball milling tank in the vertical stirring ball milling tank, the diameter of the grinding medium ball is φ0. A certain proportion of large and small balls are used together, the solvent is absolute ethanol, the dosage is just enough to...

Embodiment 1

[0029] on vertical stirring ball mill

[0030] 1) Weigh 90 grams of silver content>99.95% and particle size D prepared by liquid phase reduction method 50 Spherical silver powder with good dispersion around 2μm;

[0031] 2) Weigh 1350g of diameter φ1.5mm zirconia grinding balls into the ball milling tank, add absolute ethanol wet grinding medium until the balls are just submerged, add the above-mentioned raw material silver powder and 0.35g of oleic acid as a dispersant, start the ball mill, at 150rpm After the materials are completely stirred evenly at a low speed, the set speed is 250rpm for ball milling for 4 hours. During the ball milling process, the temperature of the water bath in the milling tank is controlled at 8°C. Mixture of silver powder and ethanol;

[0032]3) Take out the mixed solution of silver powder and ethanol, add 1:1 oleic acid and polyvinylpyrrolidone according to the liquid volume to make the dispersant concentration of the mixed solution reach 1g / L, ...

Embodiment 2

[0035] On a vertical stirring ball mill

[0036] 1) Weigh 90 grams of the product with a purity >99.95% and a particle size D prepared by the liquid phase reduction method. 50 Spherical silver powder with good dispersion around 2μm;

[0037] 2) Weigh 1350g of diameter φ3mm zirconia grinding balls and put them into the ball milling tank, add anhydrous ethanol wet grinding medium until the balls are just submerged, add the above-mentioned raw material silver powder and 0.35g of oleic acid as a dispersant, start the ball mill, at a low speed of 150rpm After the materials are completely stirred evenly, the set speed is 350rpm for ball milling for 4 hours. During the ball milling process, the temperature of the water bath in the milling tank is controlled at 8°C. the mixture;

[0038] 3) Take out the mixed solution of silver powder and ethanol, add 1:1 oleic acid and polyvinylpyrrolidone according to the liquid volume to make the dispersant concentration of the mixed solution rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| bulk density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com