Artificial joint medium layer and method of preparing the same

An artificial joint, medium layer technology, applied in joint implants, joint implants, medical science and other directions, can solve the problem of poor biological activity of hydrogels, and achieve the goal of promoting nutrient transmission, reducing friction loss, and inducing bone. effect on cell proliferation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

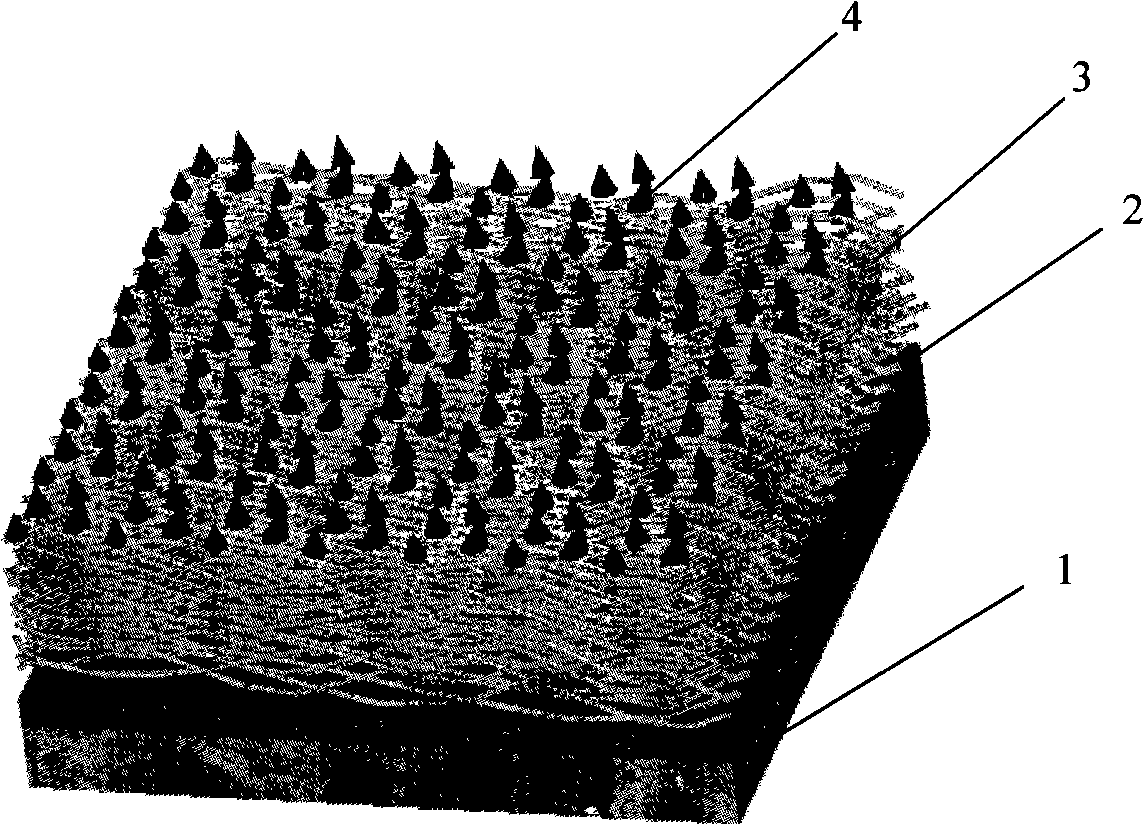

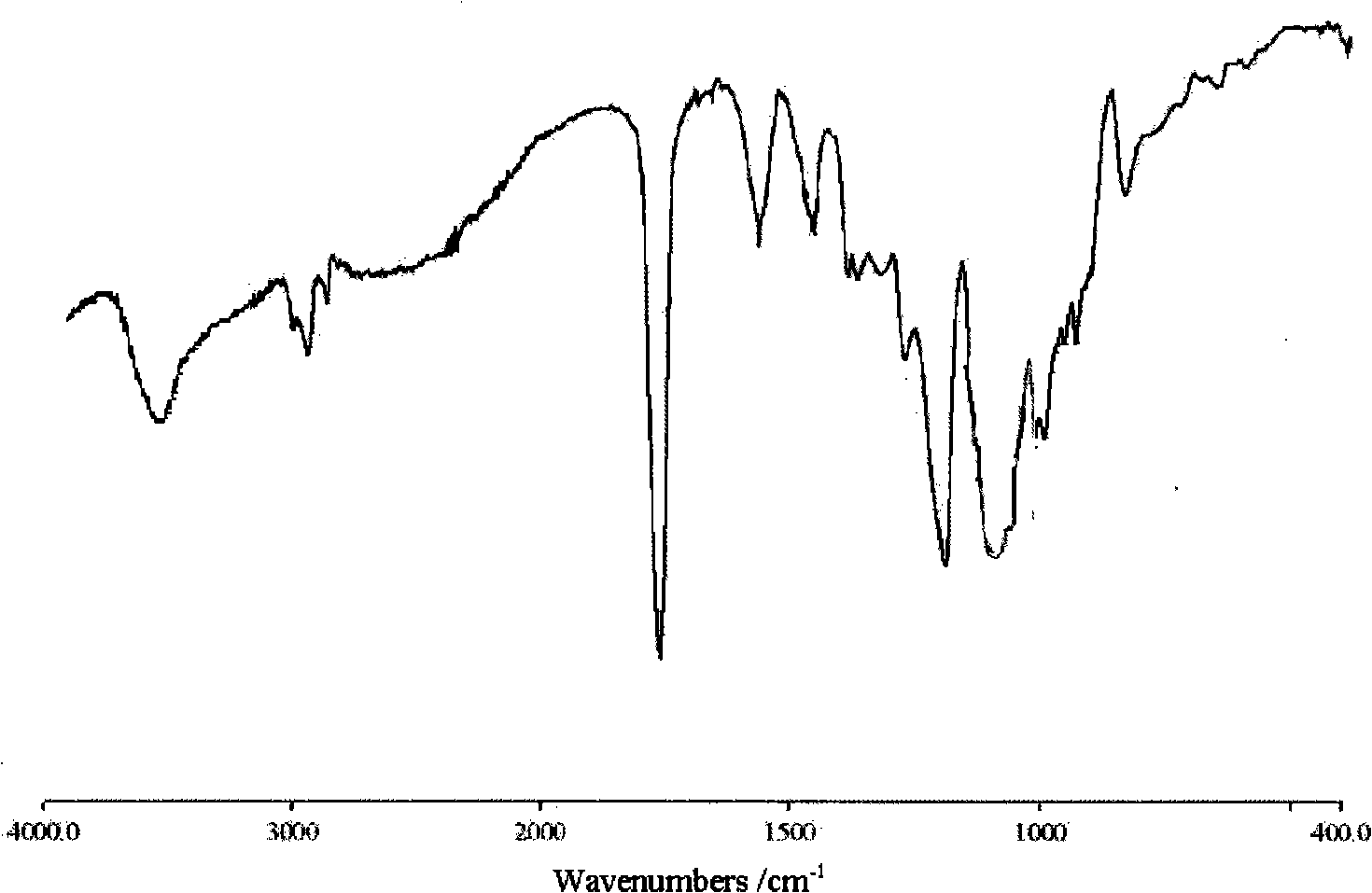

Image

Examples

Embodiment 1

[0028] 1) Prepare 1mol / L Ca(NO 3 ) 2 and P(C 2 h 5 O) 3 Ethanol solution, respectively get 400ml and 240ml and slowly mix in a 1L beaker, stir evenly, let stand for 30min, take the upper clear night, get nano-hydroxyapatite [Ca 10 (PO 4 ) 6 (OH) 2 ] (HA) sol precursor solution.

[0029] 2) The commercial titanium alloy was cut into small discs of Φ15mm×2mm, the surface was successively polished with 360, 600, 1200 and 1500# sandpaper, and then ultrasonically cleaned in ethanol and acetone for 5 minutes respectively.

[0030] 3) Immerse the treated titanium alloy sheet vertically in the precursor solution of HA sol, let it stand for 3min, lift it up vertically at a pulling speed of 2cm / min, then dry it in a vacuum oven at 150°C for 15min, and then dry it in a vacuum oven. Heat it in the furnace to 500°C, keep it warm for 15 minutes, and then cool it down in the furnace. Repeat 5 times, heat treatment in vacuum furnace at 1100°C for 60 min for the last time, and cool in...

Embodiment 2

[0041] 1) Prepare 1.5mol / L of Ca(NO 3 ) 2 and P(C 2 h 5 O) 3 Ethanol solution, respectively take 300ml and 180ml and mix slowly in a 500mL beaker, stir evenly, let stand for 20min, take the upper clear night, and obtain nano-hydroxyapatite [Ca 10 (PO 4 ) 6 (OH) 2 ] (HA) sol precursor solution.

[0042] 2) The commercial titanium alloy was cut into small discs of Φ15mm×2mm, and the surface was successively polished with 360, 600, 1200 and 1500# sandpaper, and then ultrasonically cleaned in ethanol and acetone for 10 minutes respectively.

[0043] 3) Immerse the treated titanium alloy sheet vertically in the precursor solution of HA sol, let it stand for 2min, lift it up vertically at a pulling speed of 4cm / min, then dry it in a vacuum oven at 140°C for 10min, and then dry it in a vacuum oven. Heat it in the furnace to 450°C, keep it warm for 10 minutes, and then cool it down in the furnace. Repeat 3 times, heat treatment in vacuum furnace at 1000°C for 80 min for the l...

Embodiment 3

[0048] 1) Prepare 2mol / L Ca(NO 3 ) 2 and P(C 2 h 5 O) 3 Ethanol solution, respectively take 500ml and 300ml in a 500mL beaker and mix slowly, stir evenly, let stand for 40min, take the upper clear night, get nano-hydroxyapatite [Ca 10 (PO 4 ) 6 (OH) 2 ] (HA) sol precursor solution.

[0049] 2) The commercial titanium alloy was cut into small discs of Φ15mm×2mm, the surface was successively polished with 360, 600, 1200 and 1500# sandpaper, and then ultrasonically cleaned in ethanol and acetone for 5 minutes respectively.

[0050] 3) Immerse the treated titanium alloy sheet vertically in the precursor solution of HA sol, let it stand for 1min, lift it up vertically at a pulling speed of 2cm / min, and then dry it in a vacuum oven at 160°C for 20min, then dry it in a vacuum oven. Heat it in the furnace to 550°C, keep it warm for 20 minutes, and then cool it down in the furnace. Repeat 10 times, heat treatment in vacuum furnace at 900°C for 90 min for the last time, and coo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com