Packaging material for flat electrochemical cell

A packaging material and electrochemical technology, applied in packaging, wrapping paper, sealing materials, etc., can solve problems such as peeling, loss of battery function, and rupture of hot-melt adhesive resin layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

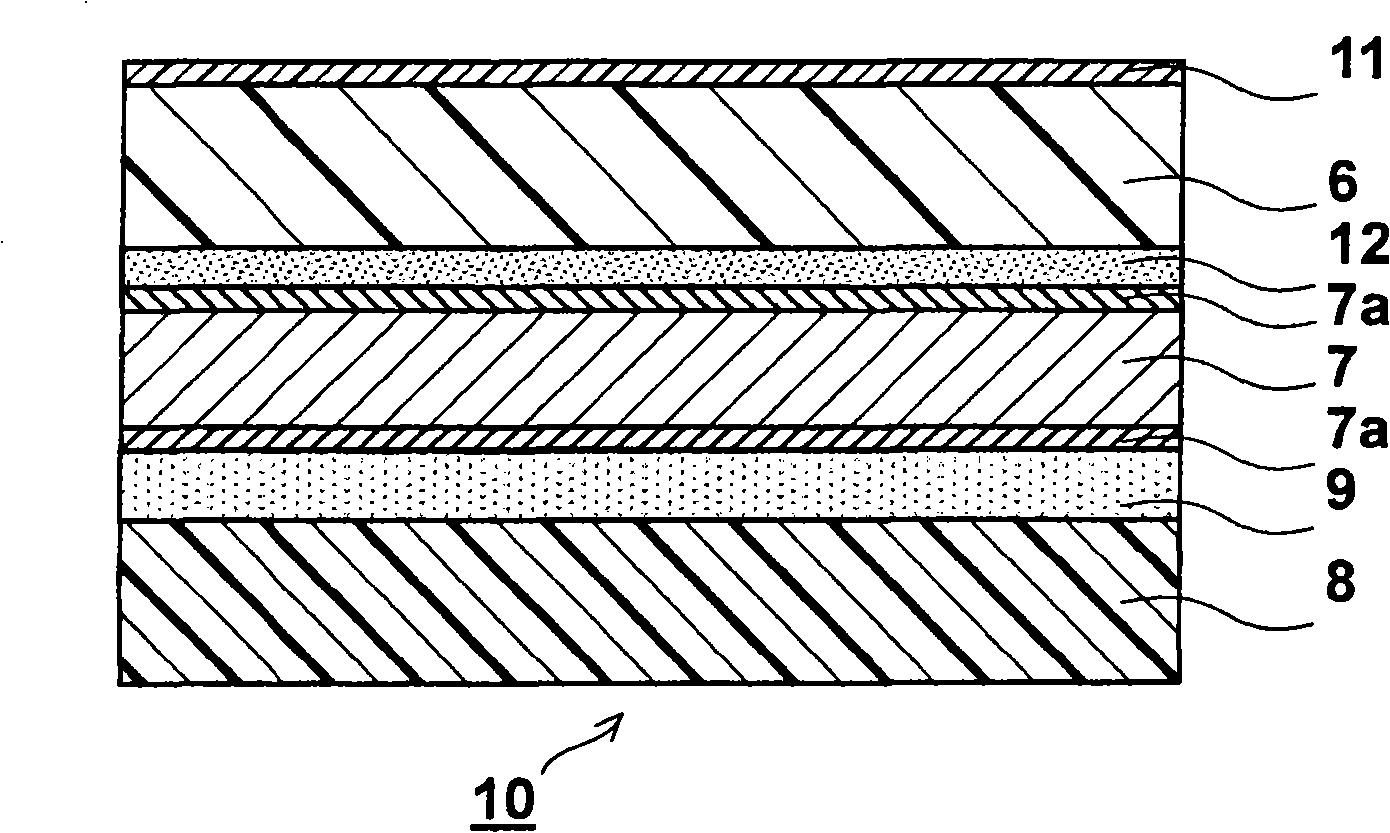

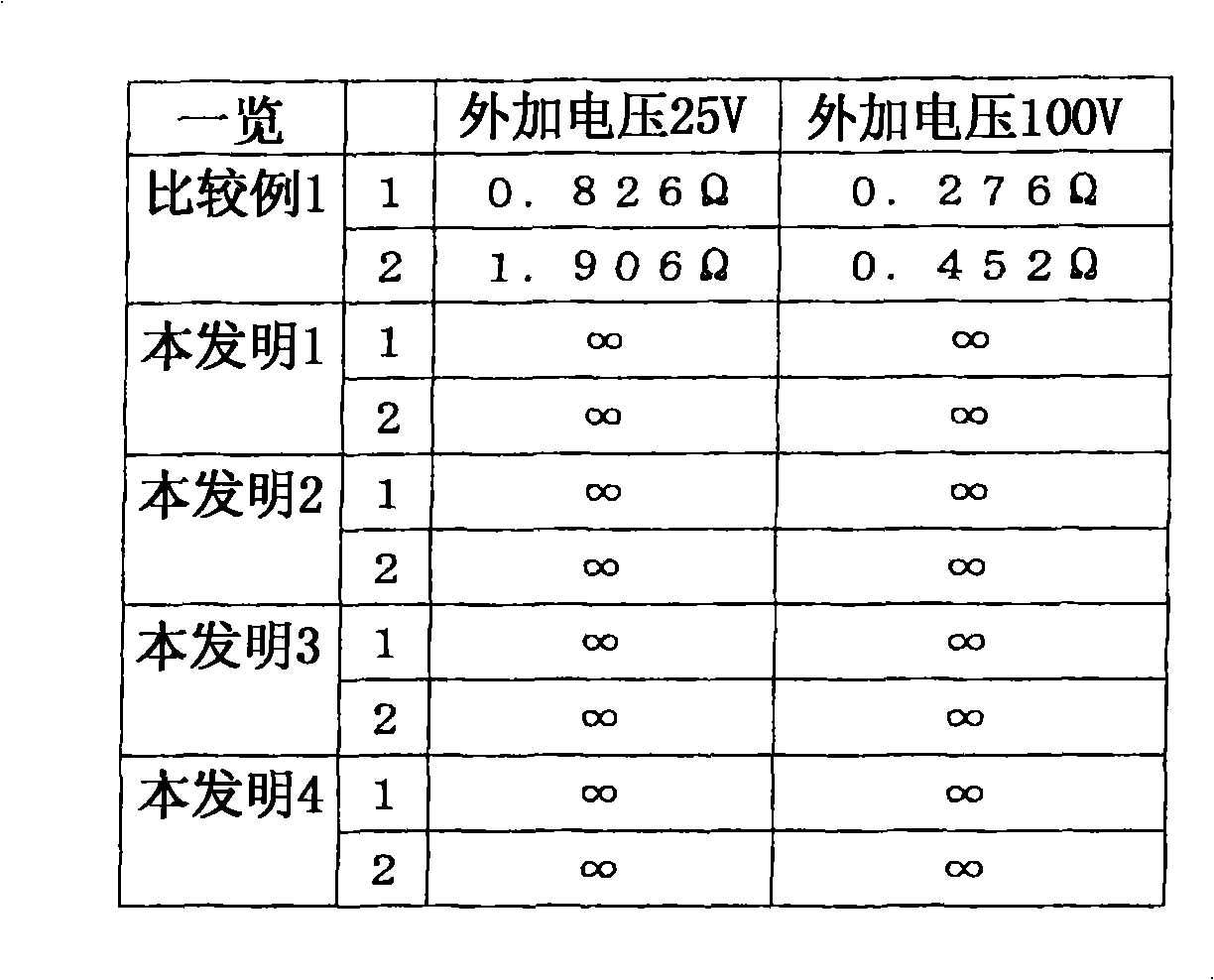

[0086] The functions and effects of the present invention will be specifically described below using examples. In Example 1, when a propylene-based elastomer resin was mixed into a polypropylene layer constituting a hot-melt adhesive resin layer, the insulation of the sealed portion after heat sealing was evaluated.

[0087] In addition, the propylene-based elastomer resin used in this example was Notiio (registered trademark) PN-2070 manufactured by Mitsui Chemicals, Ltd. The propylene-based elastomer resin contained 71 mol% of constituent units derived from propylene, and contained constituent units derived from ethylene and constituent units derived from 1-butene as constituent units other than the constituent units derived from propylene. Moreover, its physical properties are that Shore A hardness (ASTM D2240) is 75; melting point is 138°C; density (ASTM D1505) is 867kg / m 3 ; glass transition temperature (Tg) is -29°C; haze is 7%; melt flow rate (MFR, ASTM D1238) is 7.0 g...

Embodiment 2

[0099] In Example 2, when a propylene-based elastomer resin was mixed with a polypropylene layer constituting a hot-melt adhesive resin layer, the limit formability thereof was evaluated.

[0100] First, the same thing as the packaging material for electrochemical cells of Comparative Example 1 obtained in Example 1 and Inventions 1 to 4 was prepared, and cut into a square of 80×120 mm. Then each sample is put into a forming metal mold (male type) corresponding to a forming metal mold (female type) with a diameter of 30 mm × 50 mm, and it is formed into a single-side embossed outer packaging body with a depth of 7.0 mm. The main body of the lithium-ion battery was enclosed in the final outer packaging body, and the electrolyte solution was put into it to seal it with a sealing width of 5 mm.

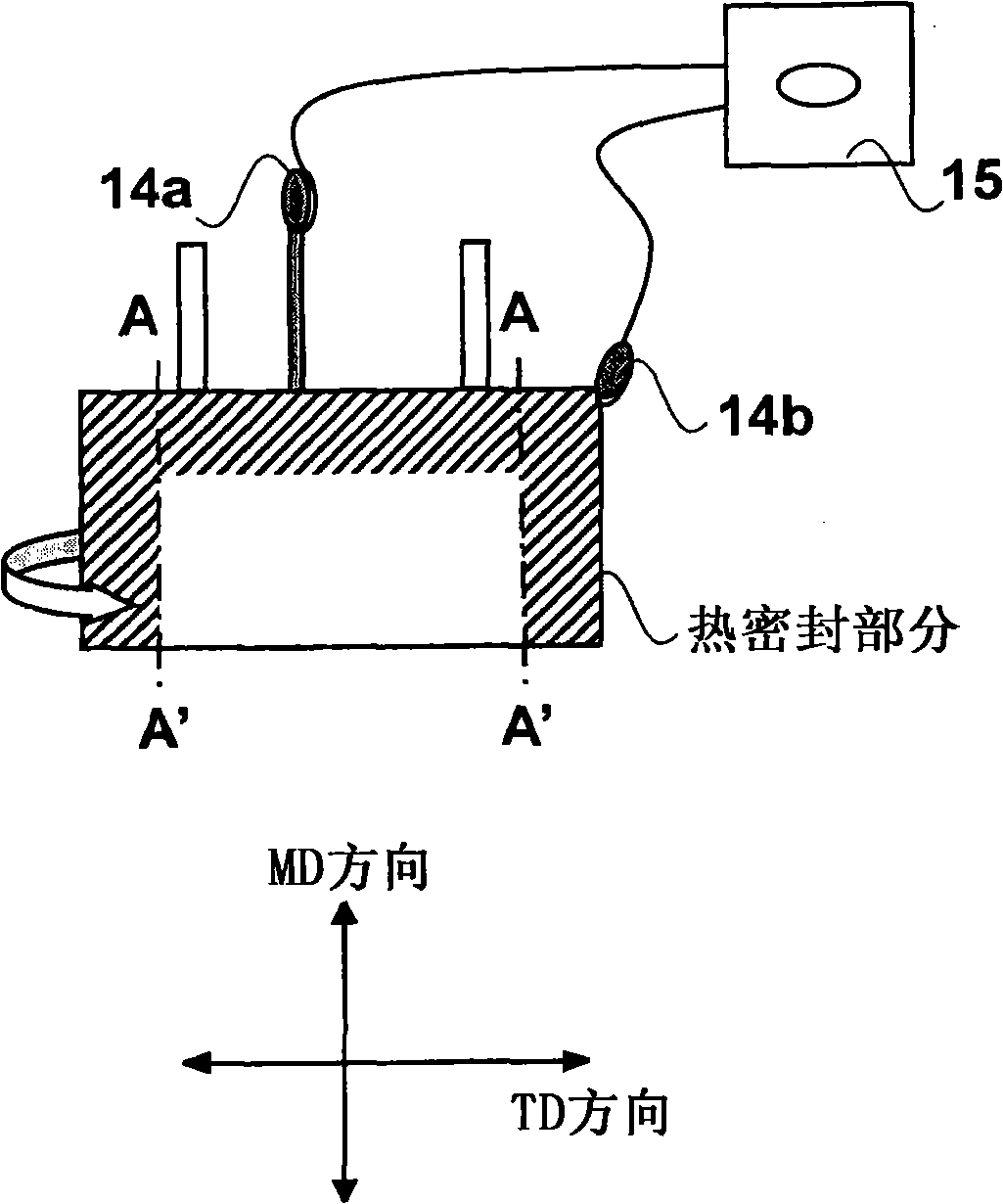

[0101]Next, put the positive terminal in the electrolyte, install the tip of the negative terminal so that it reaches the aluminum foil of the outer package, apply a voltage of 25V, 100V...

Embodiment 3

[0103] In Example 3, the sealing strength when a propylene-based elastomer resin was mixed with a polypropylene layer constituting a hot-melt adhesive resin layer was evaluated.

[0104] First, the same thing as the packing material for electrochemical cells of the comparative example obtained in Example 1 and Inventions 1-4 was prepared, and it cut into the sheet|seat of 60 mm (MD direction) x 60 mm (TD direction). Next, the sheet was folded in half in the TD direction, and the opposite sides were heat-sealed with a width of 7 mm to make a bag-shaped outer package with an opening in one direction. The surface pressure was 1.0 MPa and the sealing time was 3.0 The opening part is heat-sealed under the condition of seconds. At this time, samples were produced by changing the sealing temperature to conditions of 150°C, 170°C, 190°C, and 210°C.

[0105] Then, the heat-sealed portion on the above-mentioned opening portion of these samples is cut into a thin rectangular shape with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com