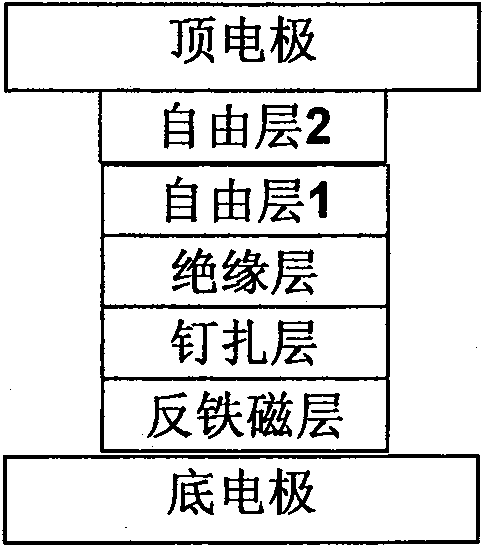

Double freedom layer vertical ferromagnetism tunnel junction structure

A ferromagnetic and tunnel junction technology, applied in the field of magnetic random access memory, can solve problems such as destroying magnetic units, and achieve the effect of reducing energy loss and reducing critical current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

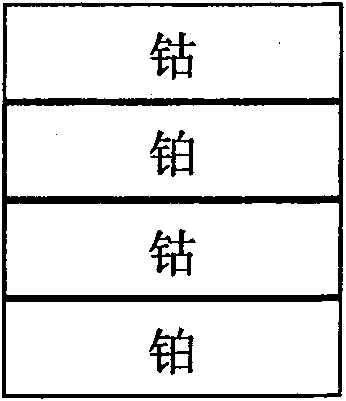

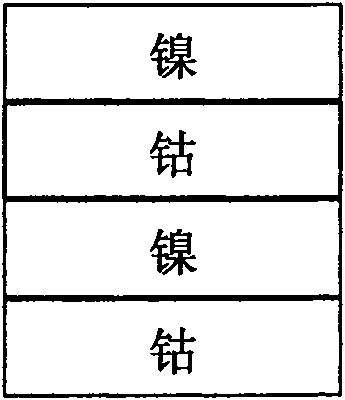

[0020] According to the above structure, the following 44 kinds of MTJ multilayer film structures were prepared by magnetron sputtering or molecular beam epitaxy, and MTJ devices were prepared by electron beam printing and ion etching: its characteristic is that the working current is perpendicular to plane, and the pinning layer and free layer 1 are the film planes with magnetic anisotropy perpendicular to the easy axis, and the free layer 2 is the film plane with magnetic anisotropy parallel to the easy axis. The detailed preparation process of the above MTJ is as follows: the background vacuum degree of the sputtering chamber is 2×10 -5 Pa, the pressure of argon (99.99%) during sputtering is 0.5Pa; the substrate is cooled with circulating water, and a magnetic field of 50Oe is added to the direction of the pinned layer and the free layer 1 perpendicular to the substrate to induce a vertical easy magnetization direction; A magnetic field of 250Oe is added to the free layer 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com