Method for preparing nano soft magnetic manganese-zinc ferrite

A manganese-zinc ferrite and soft magnetic technology, which is applied in the direction of inorganic material magnetism, can solve the problems of low product yield, high cost, high energy consumption, etc., and achieve high product yield, improved magnetic performance, and low production cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The first step is the preparation of manganese-zinc ferrite nano-powder

[0028] First take 30ml FeSO with a concentration of 1mol / L 4 Solution, adjust its pH value to 8.70 with 6M NaOH solution, and then add 1.6ml of H with a mass percentage concentration of 27.5% 2 O 2 , Which is 0.015mol of H 2 O 2 Carry out oxidation, react for 30-40 minutes, then adjust the pH value of the suspension to 13.00 with a NaOH solution with a concentration of 6mol / L, and then the molar ratio is Fe 2+ : Mn 2+ : Zn 2+ =1:0.33:0.17, add 9.9ml of MnSO with a concentration of 1mol / L 4 Solution and 5.1ml ZnSO with a concentration of 1mol / L 4 The resulting suspension is boiled and refluxed for 8 hours to form black manganese-zinc ferrite nanocrystals. Then, 30ml of citric acid with a mass percentage concentration of 4.76% is used for ultrasonic dispersion for 20 minutes. The mass ratio of iron ions is 1:4.4, and then drying and grinding are carried out in an oven ≤50°C to obtain nano-manganese-zinc...

Embodiment 2

[0035] The first step is the preparation of manganese-zinc ferrite nano-powder

[0036] The same as in Example 1.

[0037] The second step is to press into a ring-shaped blank

[0038] The same as in Example 1.

[0039] The third step is to sinter the product

[0040] Put the formed blank prepared in the second step into a tubular resistance furnace, and under the protection of nitrogen, increase the temperature from room temperature to 900°C at a rate of 5°C / min. Then, after 10 minutes of natural cooling, the temperature drops to At 850°C, keep it at this temperature for 2 hours, then cool it naturally to room temperature, and finally obtain a soft magnetic manganese-zinc ferrite sintered body, that is, a nano soft magnetic manganese-zinc ferrite product.

[0041] image 3 This is the scanning electron micrograph of the nano soft magnetic manganese-zinc ferrite product prepared in this example. It can be seen from the figure that the nano soft magnetic manganese-zinc ferrite mat...

Embodiment 3

[0043] The second step is to press into a ring-shaped blank

[0044] The same as in Example 1.

[0045] The third step is to sinter the product

[0046] Put the formed blank prepared in the second step into a tubular resistance furnace, and under the protection of nitrogen, increase the temperature from room temperature to 1100°C at a rate of 5°C / min. Then, after 20 minutes of natural cooling, the temperature drops to At 850°C, keep it at this temperature for 2 hours, then cool it naturally to room temperature, and finally obtain a soft magnetic manganese-zinc ferrite sintered body, that is, a nano soft magnetic manganese-zinc ferrite product.

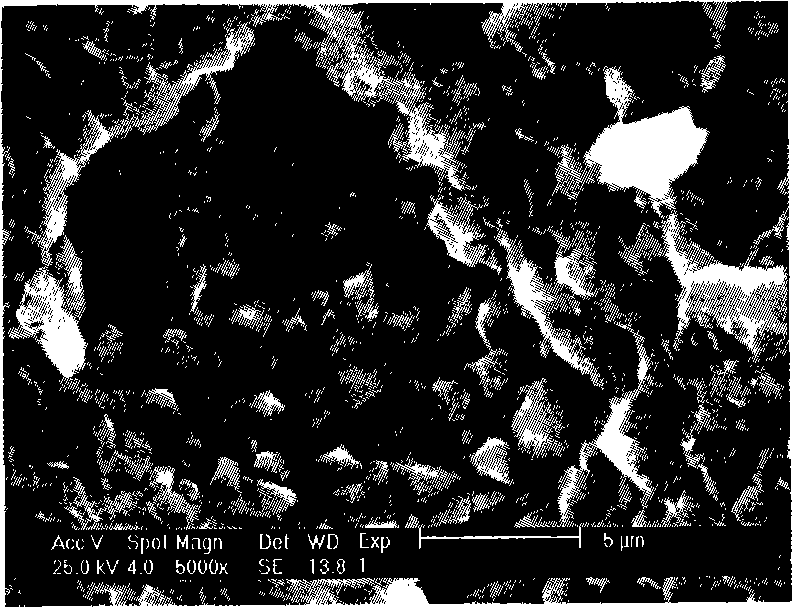

[0047] Figure 4 This is the scanning electron micrograph of the nano soft magnetic manganese-zinc ferrite product prepared in this example. It can be seen from the figure that the nano-soft magnetic manganese-zinc ferrite material has fewer internal pores, uniform and dense particles, and an average particle size of 3 to 4 μm. This shows...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com