Polypropylene open-cell foaming material and preparing process thereof

A porous material, polypropylene technology, applied in the field of polypropylene foamed open-cell material and its preparation, can solve the problems of flammability, explosion, environmental impact, etc., and achieve the effects of environmental friendliness, low cost, and wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] 1) Put 97 parts of resin matrix, 1 part of talc powder with an average particle size of 0.8 μm, and 2 parts of glycerol monostearate into a high-speed mixer and mix thoroughly, wherein the resin matrix is made of 99 parts of polypropylene resin (F401 of Panjin Petrochemical, The melt flow rate (MFR) is 2.0g / 10min, measured according to the standard ISO1133:1997) and 1 part of ultra-high molecular weight polyethylene with a weight average molecular weight of 5 million;

[0040] 2) Put the mixture obtained in step 1) into a twin-screw extruder with a screw diameter of 32mm and an aspect ratio of 48 through the feeding port. The temperatures of each section of the extruder are 150°C, 170°C, 180°C, 190°C, and 190°C. , 200°C, 200°C, extruding strips through a circular die, cooling with water, and cutting into pellets to obtain a polypropylene resin composition;

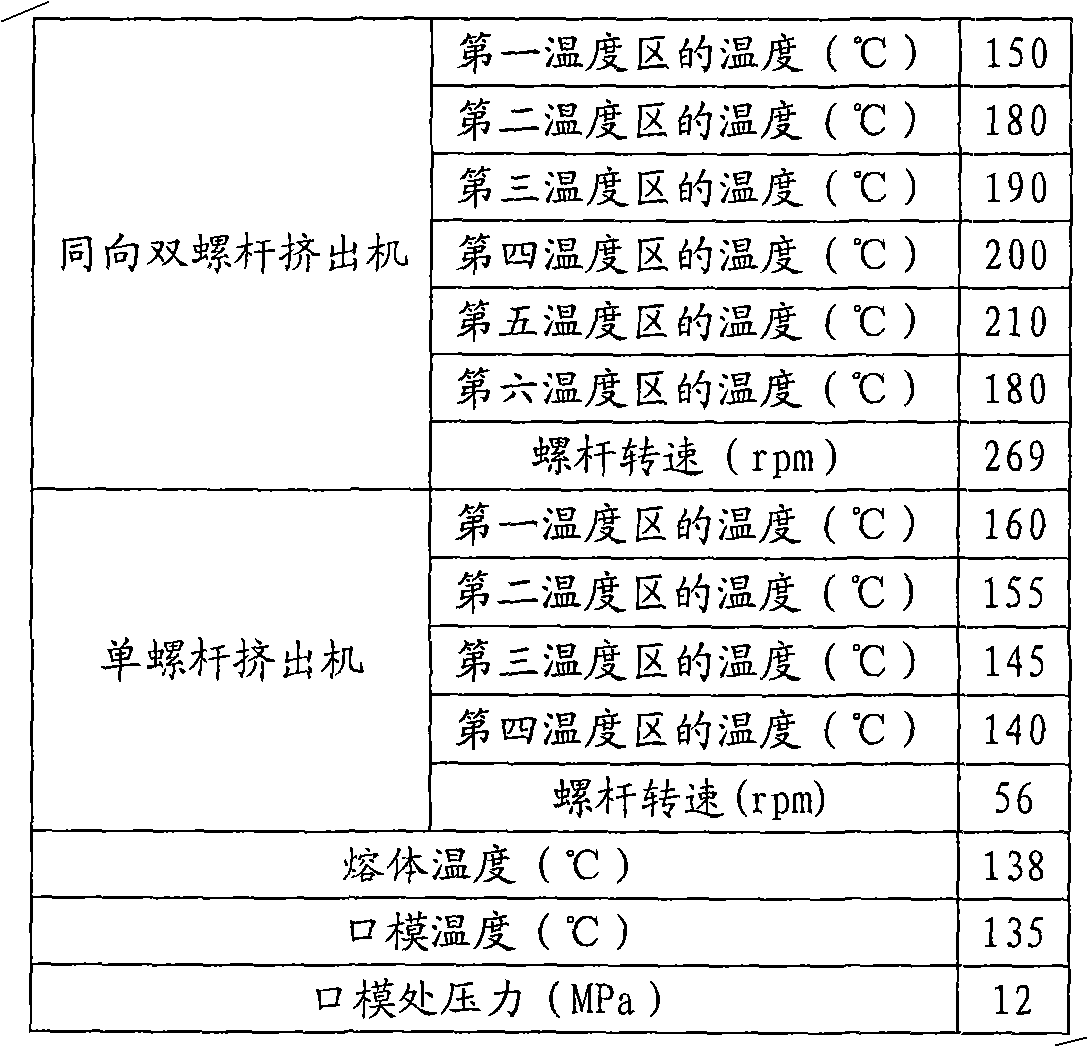

[0041] 3) Add the polypropylene resin composition obtained in step 2) into a twin-screw extruder with a screw d...

Embodiment 2

[0046] 1) Put 95 parts of resin matrix, 2 parts of talcum powder with an average particle size of 0.8 μm, and 3 parts of glycerol monostearate into a high-speed mixer and mix thoroughly, wherein the resin matrix is made of 92 parts of polypropylene resin (Qilu Petrochemical Copolymerized Polypropylene EP2S34F, melt flow rate (MFR) is 1.8g / 10min, measured according to standard ISO1133:1997), 3 parts of ultra-high molecular weight polyethylene with a weight average molecular weight of 4 million and 5 parts of EPDM rubber (Jilin Petrochemical J3080) composition;

[0047] 2) Put the mixture obtained in step 1) into a twin-screw extruder with a screw diameter of 32mm and an aspect ratio of 48 through the feeding port. The temperatures of each section of the extruder are 150°C, 170°C, 180°C, 190°C, and 190°C. , 200°C, 200°C, extruding strips through a circular die, cooling with water, and cutting into pellets to obtain a polypropylene resin composition;

[0048] 3) Add the polypr...

Embodiment 3

[0052] 1) Put 95 parts of resin matrix, 2 parts of talcum powder with an average particle size of 0.8 μm, and 3 parts of glycerol monostearate into a high-speed mixer and mix thoroughly, wherein the resin matrix is made of 90 parts of polypropylene resin (Qilu Petrochemical Copolymerized Polypropylene EP2S34F, melt flow rate (MFR) is 1.8g / 10min, measured according to standard ISO1133:1997), 5 parts of ultra-high molecular weight polyethylene with a weight average molecular weight of 3 million and 5 parts of EPDM rubber (Jilin Petrochemical J3080) composition;

[0053] 2) Put the mixture obtained in step 1) into a twin-screw extruder with a screw diameter of 32mm and an aspect ratio of 48 through the feeding port. The temperatures of each section of the extruder are 150°C, 170°C, 180°C, 190°C, and 190°C. , 200°C, 200°C, extruding strips through a circular die, cooling with water, and cutting into pellets to obtain a polypropylene resin composition;

[0054] 3) Add the polypr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com