Double-arm automobile frame turnover device

A frame-turning, double-arm type technology, applied to workbenches, manufacturing tools, etc., can solve problems such as potential safety hazards, inability to stop stably, low efficiency, etc., and achieve high safety level, high practical value, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

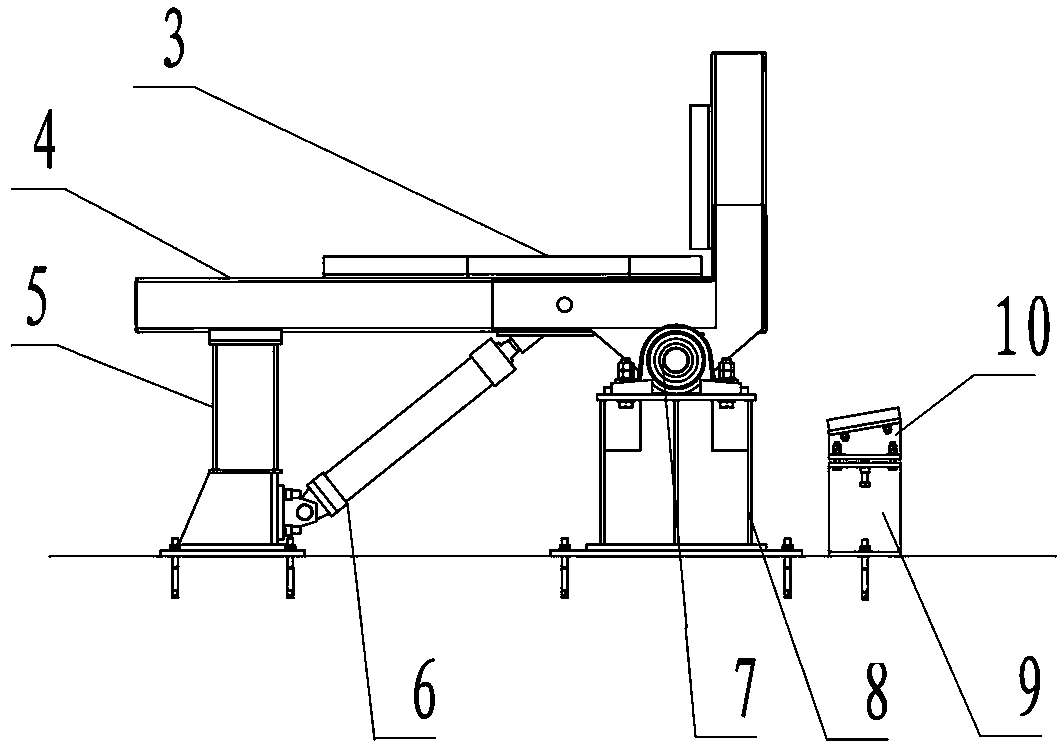

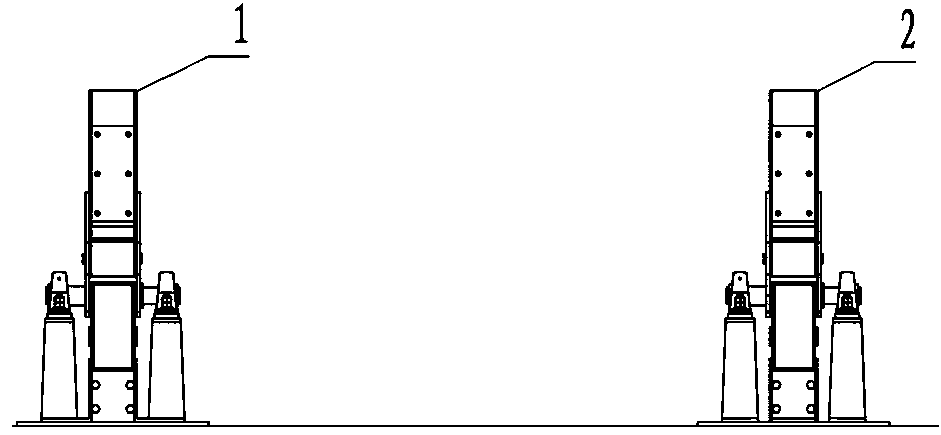

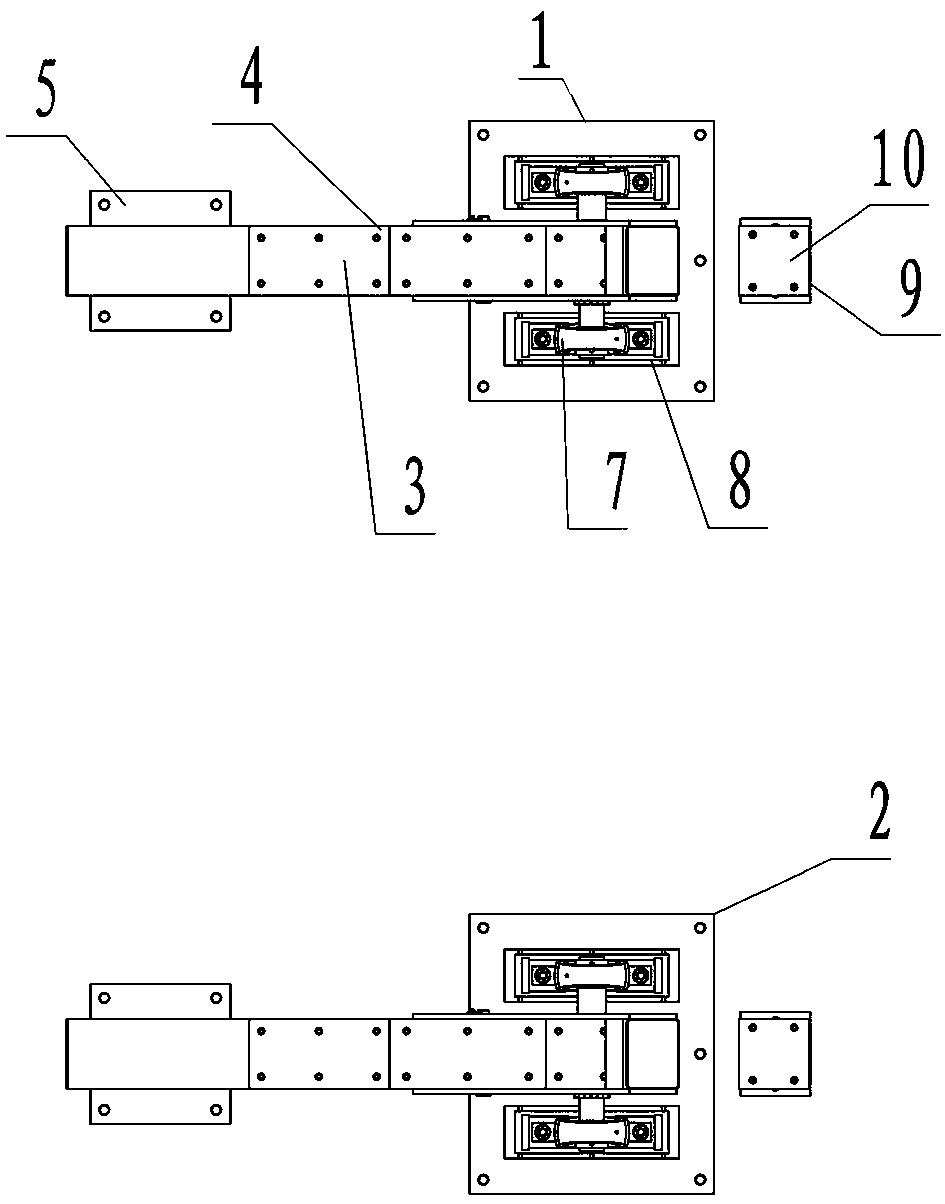

[0019] figure 1 , figure 2 and image 3 The double-arm frame turning device comprises two turning arms independently installed in parallel, namely turning arm 1 and turning arm 2, a hydraulic control system for controlling the operation of the turning arm and a limit block base 9 installed directly in front of the turning arm; An angle limit block 10 is installed on the limit block base 9; the flip arm includes two bearing blocks 8 and an oil cylinder support seat 5 fixedly installed side by side on the ground, and the bearing block 8 is equipped with a bearing 7 and is composed of mutually perpendicular long arms and The L-shaped overturning support plate 4 formed by the short arm, the support surface of the long arm and the short arm is fixed with a buffer support block 3 through a positioning hole, and the buffer support block 3 carries the frame to prevent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com