COG dielectric composition for use with nickel electrodes

A technology of dielectric and composition, applied in the field of zirconium titanate-based dielectric composition, can solve problems such as capacitance aging, and achieve the effects of stable dielectric constant, small dielectric loss and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

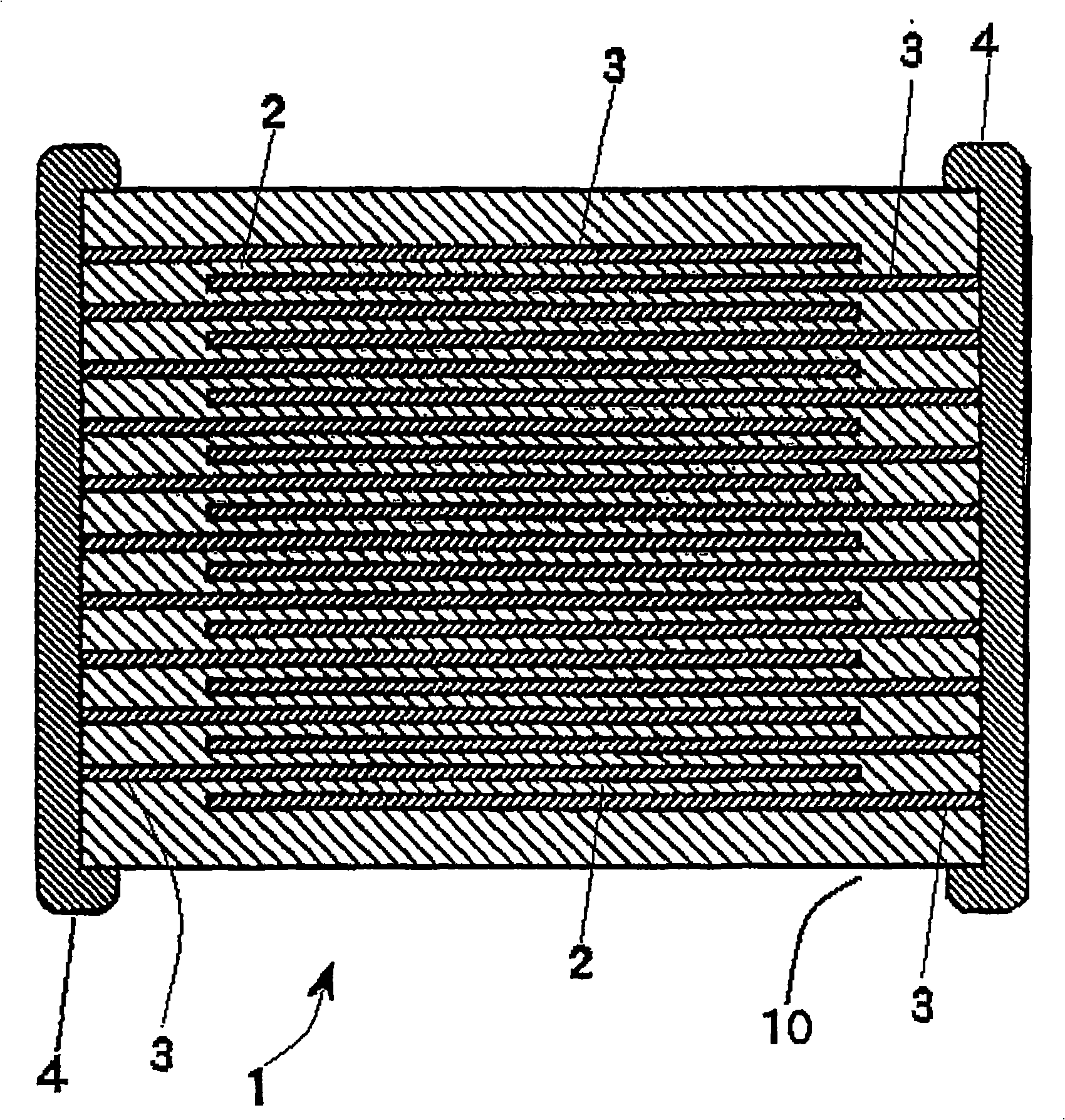

Image

Examples

Embodiment 1

[0051] The dielectric composition referred to as Precursor 1 was formed by mixing, compounding and / or milling the appropriate amount of oxides as shown in Table 6 in water. Mix the powder with 1% of C (a polymer suspending agent available from RT Vanderbilt Co., Inc., Norwalk, Connecticut) was mixed. Bead mill the mixed powder to particle size D with 0.5mm YTZ (stabilized yttrium zirconia) 50 is about 0.65 microns. The powder was calcined at 1200°C for 5 hours. Then, the calcined powder was pulverized by a conventional method to obtain a precursor 1 .

[0052] Table 6. Formulation of Precursor 1 before calcination

[0053] SrCO 3

ZrO 2

TiO 2

wt%

54.901

43.761

1.337

[0054] Additionally, after calcination, the composition of Precursor 1 can be represented by the following formula: SrZr 0.955 Ti 0.045 o 3 . According to the formula in Table 7, 2MgO·3B 2 o 3 (as Mg(OH) 2 and H 3 BO 3 combination) was added t...

Embodiment 2

[0068] According to Table 11, the Mg(OH) 2 , CaCO 3 、Al 2 o 3 and SiO 2 The mixture of is added to the precursor 1 as a sintering aid (after sintering to efficiently produce MgO-CaO-Al 2 o 3 -SiO 2 ). The powder was processed according to Example 1.

[0069] Table 11. Recipe for the dielectric of Example 2 prior to firing

[0070] precursor 1

Mg(OH) 2

CaCO 3

Al 2 o 3

SiO 2

wt%

97.812

0.257

0.257

0.579

1.096

[0071] The powder of Example 2 has the general formula which can alternatively be expressed as: 98.003 wt% SrZr 0.955 Ti 0.045 o 3 +0.178wt% MgO+0.144wt% CaO+0.579wt% Al 2 o 3 +1.096wt% SiO 2 . Example 2 has the formulation of Table 12 when expressed as a simple oxide.

[0072] Table 12. Oxide composition of the dielectric powder of Example 2

[0073] SrO

ZrO 2

TiO 2

MgO

CaO

Al 2 o 3

SiO 2

wt%

45.156

51.281

...

Embodiment 3-14

[0078] Various amounts of mixtures including MgO, CaO, Al 2 o 3 , SiO 2 And / or any one or all of SrO. Since the sintering aid in Examples 12, 13 and 14 also contained SrO, the total SrO in these examples was derived from both Precursor 1 and the sintering aid. For Examples 3-14, the total weight of Precursor 1 is the first three columns (SrO, ZrO 2 and TiO 2 )Sum. The composition and MLCC electrical properties of Example 2 are also included in Tables 14 and 15 for ease of comparison.

[0079] Table 14. Oxide composition (expressed in wt %) of the powders of Examples 2-14

[0080] implement

[0081] The final powders of Examples 3-14 were processed according to the procedure of Example 1 to prepare MLCC flakes for electrical testing. Firing conditions and electrical properties are summarized in Table 15. Each MLCC was fired for 2 hours.

[0082] Table 15. Firing conditions and electrical properties of MLCCs of Examples 2d-15

[0083] Example

[008...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com