Method for preparing conductive fiber reinforced concrete base functional composite material

A technology of functional composite materials and conductive fibers, which is applied in the field of preparation of cement-based functional composite materials, can solve problems such as poor fiber dispersion, low electrical conductivity, and broken fibers, and achieve good fiber dispersion, good electrical conductivity, Effect of improved vibration damping performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

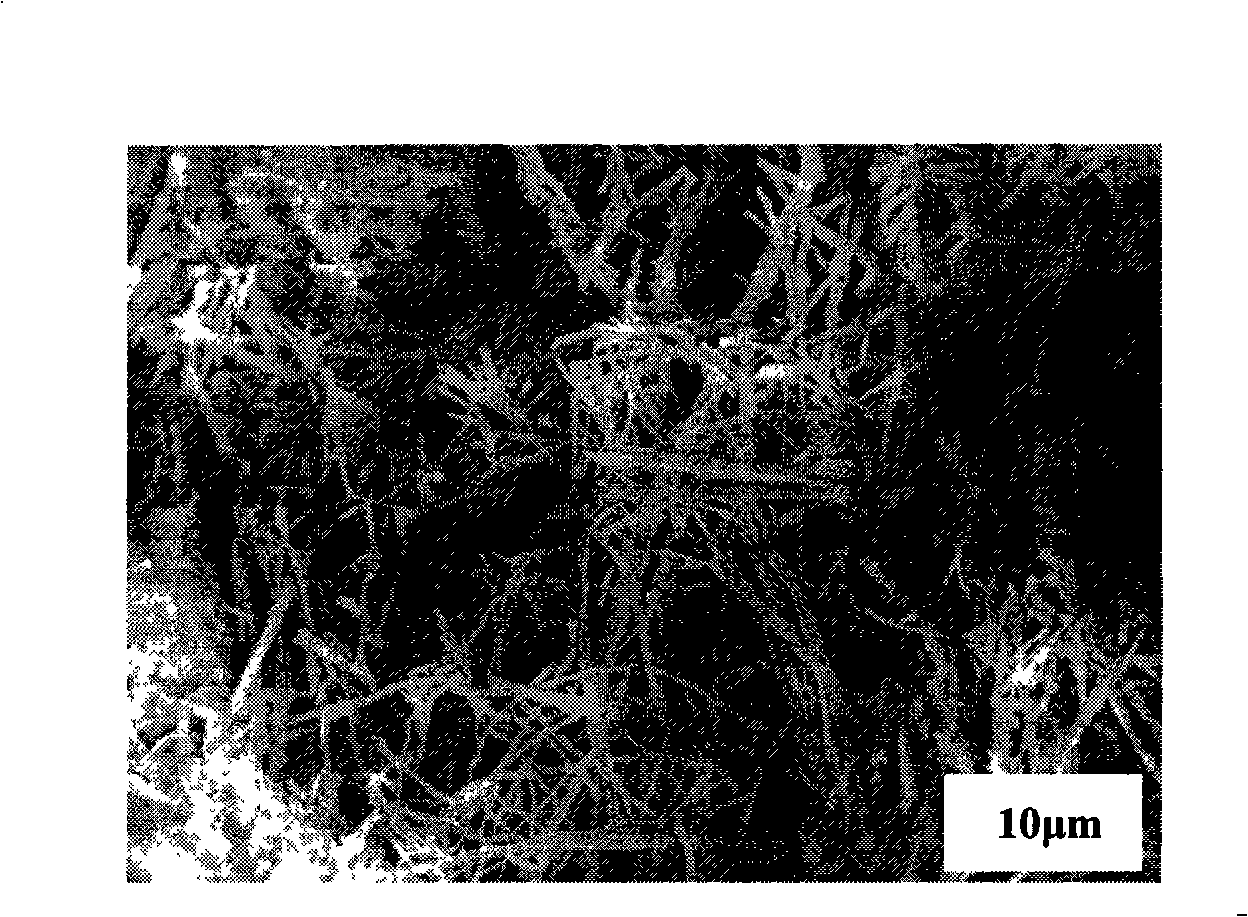

Image

Examples

specific Embodiment approach 1

[0007] Embodiment 1: In this embodiment, a method for preparing a conductive fiber reinforced cement-based functional composite material is realized according to the following steps: 1. Dissolve the conductive fiber dispersant in a volatile organic solvent to obtain a concentration of 0.1 to 10%. solution, and then add conductive fibers to the solution, magnetically stir and ultrasonically treat for 10-180 minutes to obtain a dispersed phase liquid of conductive fibers; 2. Add deionized water, superplasticizer, early strength agent, polymer emulsion, mineral After mixing with the cement mixing machine, put it into the insulating test mold, leveling and vibrating to prepare the cement slurry matrix; 3. Add the conductive fiber dispersion phase to the cement slurry matrix after the initial setting and before the final setting liquid, and apply a DC or AC electric field to the conductive fiber dispersed phase liquid for 1 to 3 hours, and obtain a composite body of cement matrix an...

specific Embodiment approach 2

[0008] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the conductive fiber in step one is a mixture of one or more of carbon fibers, conductive silver-plated fibers, conductive aluminum-plated fibers, conductive nanofibers, and carbon nanotubes . Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0009] Specific embodiment three: the difference between this embodiment and specific embodiment one is that the conductive fiber dispersant in step one is methyl cellulose, carboxymethyl cellulose, carboxyethyl cellulose, nonylphenol polyoxyethylene ether, Arabica Glue, sodium dodecylbenzenesulfonate, sodium polyacrylate, cetyltrimethylammonium bromide or a mixture of several. Other steps and parameters are the same as those in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com