Silver base cadmiumless middle temperature solder and preparation thereof

A silver-based, medium-temperature technology, used in manufacturing tools, welding equipment, metal processing equipment, etc., can solve the problems of high cost, narrow application range, poor technical indicators such as solder melting temperature and melting range, etc. The effect of good plasticity and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

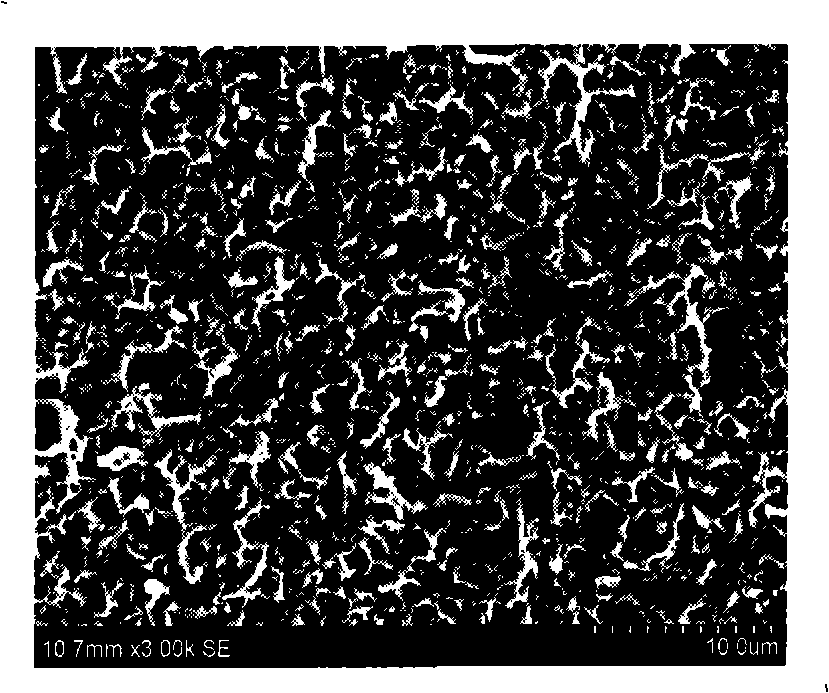

Image

Examples

specific Embodiment approach 1

[0008] Specific Embodiment 1: The silver-based cadmium-free medium-temperature solder of this embodiment consists of 19-20 parts of Ag, 13.04-37.61 parts of electrolytic copper, 32-33 parts of Zn, 2.5-8.0 parts of Sn, 2.14 to 8.56 parts of copper-phosphorus alloy with a phosphorus content of 14%, 1.5 to 2.0 parts of Mn, 0.2 to 0.7 parts of Zr, and 5.05 to 10.8 parts of rare earth lanthanum wrapped in copper foil; the rare earth wrapped in copper foil The lanthanum is made of 5.0-10.0 parts of copper foil and 0.05-0.8 parts of rare earth lanthanum in parts by weight.

[0009] The rare earth lanthanum coated with copper foil is prepared as follows: put 0.05-0.8 parts of rare earth lanthanum into the center of 5.0-10.0 parts of copper foil, and wrap the rare earth lanthanum tightly with copper foil.

specific Embodiment approach 2

[0010] Specific embodiment two: the silver-based cadmium-free medium-temperature brazing filler metal of the present embodiment is by weight the phosphorus content of the Ag of 19.5 parts, the electrolytic copper Cu of 25.5 parts, the Zn of 32.5 parts, the Sn of 6.0 parts, 6.0 parts is 14% copper-phosphorus alloy, 1.7 parts of Mn, 0.5 parts of Zr and 8.4 parts of rare earth lanthanum wrapped in copper foil; wherein the rare earth lanthanum wrapped in copper foil consists of 8.0 parts of copper foil and 0.4 parts of Made of rare earth lanthanum.

specific Embodiment approach 3

[0011] Specific embodiment three: The silver-based cadmium-free medium-temperature solder described in specific embodiment one is prepared as follows: 1. By weight, 0.2 to 0.7 parts of zirconium, 1.5 to 2.0 parts of manganese and 13.04 to 37.61 parts of electrolytic Put the copper into the crucible of the intermediate frequency furnace, heat up to 650-850°C, add a covering agent on the surface of the alloy, continue to heat up to 1100-1250°C, and add 2.14-8.56 parts of phosphorus containing 14% (weight ) of copper-phosphorus alloy and 32-33 parts of zinc, after melting, stir at a speed of 15-20r / min, then add 19-20 parts of silver and 2.5-8.0 parts of tin, and then add a covering agent for 3-5 minutes After cooling down to 980-1050°C, add 5.05-10.8 parts of rare earth lanthanum wrapped in copper foil, and stir at a speed of 15-20r / min to remove slag when the furnace smoke turns milky white. Cool down to 950-1000°C and release 2. Casting: remove the air bubbles contained in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com