Coating composition and its manufacturing method, and resin molding and its manufacturing method

A technology of resin molded body and manufacturing method, which is applied to the device, coating, transportation and packaging of surface coating liquid, which can solve the problems of easy condensation, temperature rise, photocatalyst performance degradation, etc., and achieve excellent coating fabric effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0540] [Manufacture of silica and measurement of physical properties]

[0541] 1000 g of pure water was poured into a 5 L detachable glass flask (jacketed) equipped with an open water-cooled condenser on the top. While stirring at 80 rpm, 1400 g of tetramethoxysilane was injected over 3 minutes.

[0542] The water / tetramethoxysilane molar ratio is about 6 / 1. Warm water at 50°C was circulated in the jacket of the detachable flask. Stirring is continued until the contents reach boiling point. Warm water at 50°C was recirculated for about 0.5 hour to gel the resulting sol.

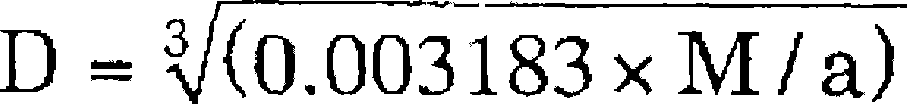

[0543] Thereafter, the gel was quickly taken out, and the gel was pulverized into a powdery wet gel (silica hydrogel) through a nylon sieve with a mesh size of 600 μm. After putting 450 g of the hydrogel and 450 g of pure water into a 1 L glass autoclave, a hydrothermal treatment was performed at 180° C. for 3 hours. The solution was filtered through a nylon sieve with a mesh size of 100 μm, and the filt...

Embodiment 2

[0559] With the weight ratio of 8.3: 16.7: 67.5: 7.5, with the same process as in Example 1, the same silica as in Example 1, the acrylic latex aqueous dispersion used in Example 1, methanol and methyl ethyl The ketones were mixed and stirred to prepare a slurry composition (viscosity: 92 mPa·s) (referred to as the coating composition of Example 2).

[0560] Using a bar coater, the obtained coating composition of Example 2 was coated on a polyvinyl chloride sheet (thickness: 0.5 mm), and dried at room temperature, thereby preparing a coating with a thickness of 21 μm. The humidity-conditioning sheet of the wet layer (referred to as the resin molded article of Example 2).

Embodiment 3

[0562] With the weight ratio of 15.0: 10.0: 67.5: 7.5, in the same process as in Example 1, the same silica as in Example 1, the acrylic latex aqueous dispersion used in Example 1, methanol and methyl ethyl The ketones were mixed and stirred to prepare a slurry composition (viscosity: 52 mPa·s) (referred to as the coating composition of Example 3).

[0563] Using a bar coater, the obtained coating composition of Example 3 was coated on a polyvinyl chloride sheet (thickness: 0.5 mm), and dried at room temperature to prepare a sheet with a thickness of 47 μm. The humidity-conditioning sheet of the humidity-conditioning layer (referred to as the resin molded article of Example 3).

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com