Oxidate magnetic semiconductor thin film capable of regulating electric transport property and method of preparing the same

A magnetic semiconductor and electrical transport technology, applied in the field of information technology spintronic materials, can solve the problems of regulation, unknown electron transport properties, unclear reasons for the electrical transport properties of oxide magnetic semiconductor thin film materials, etc. The effect of high Curie temperature and large magnetism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

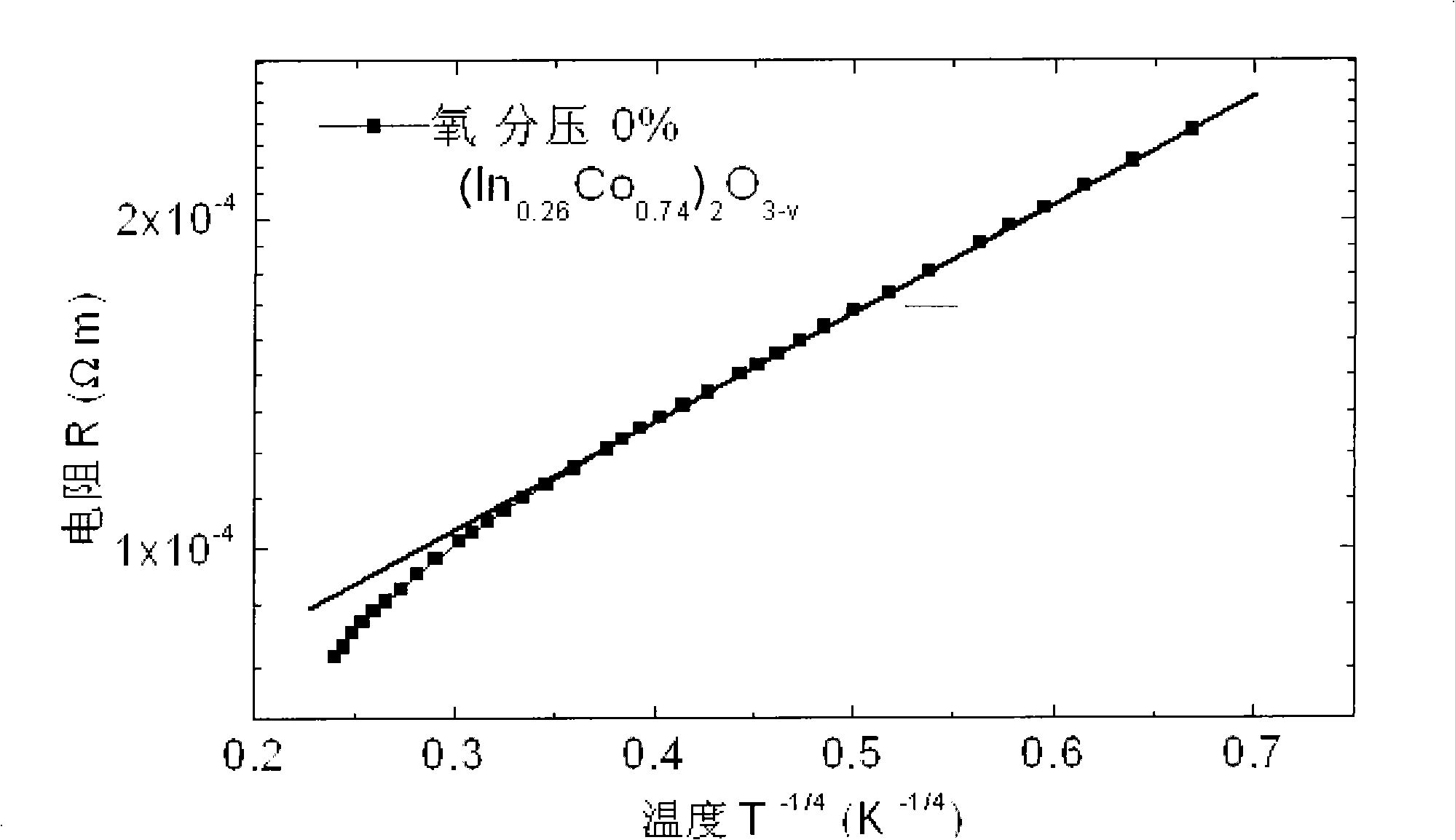

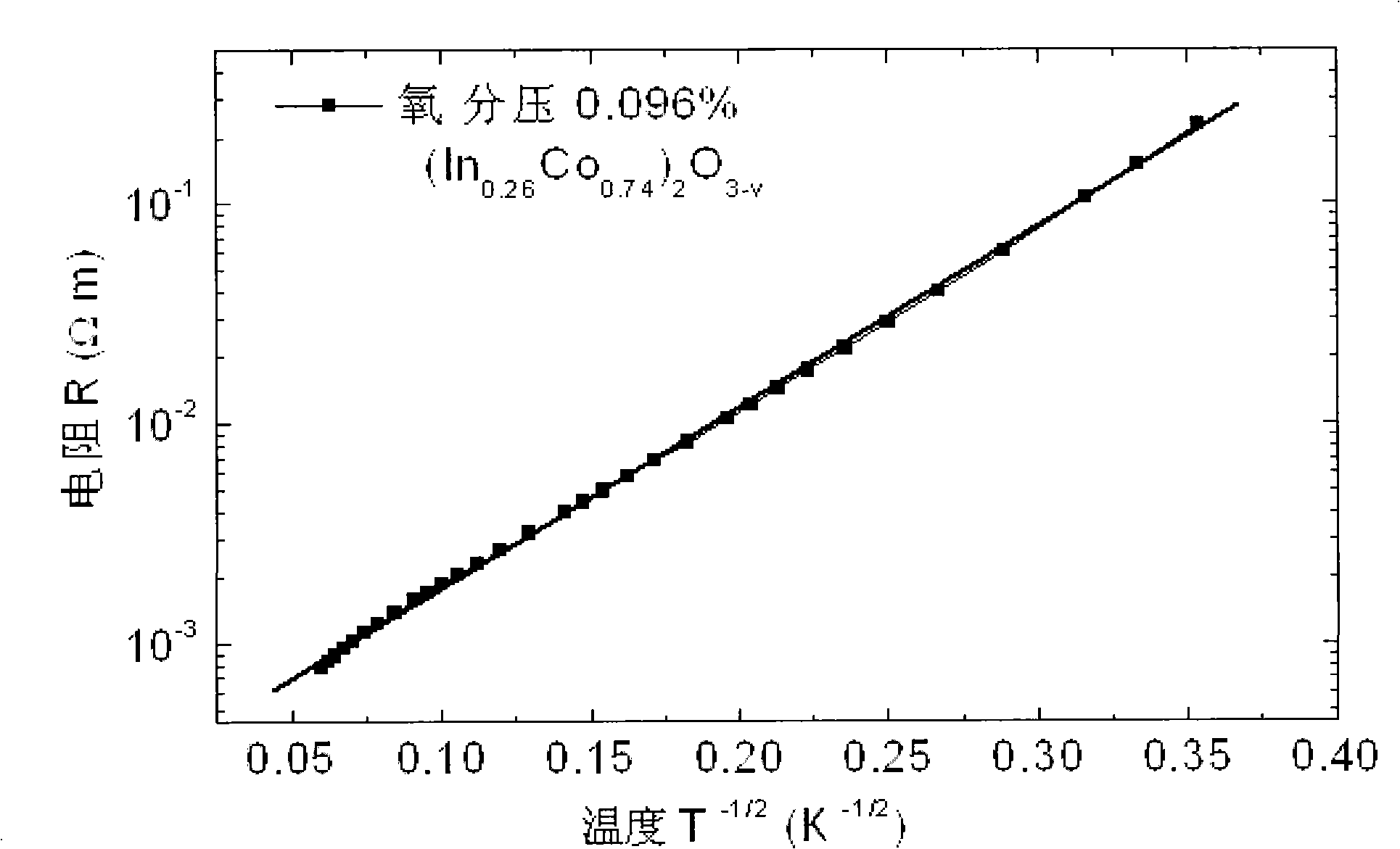

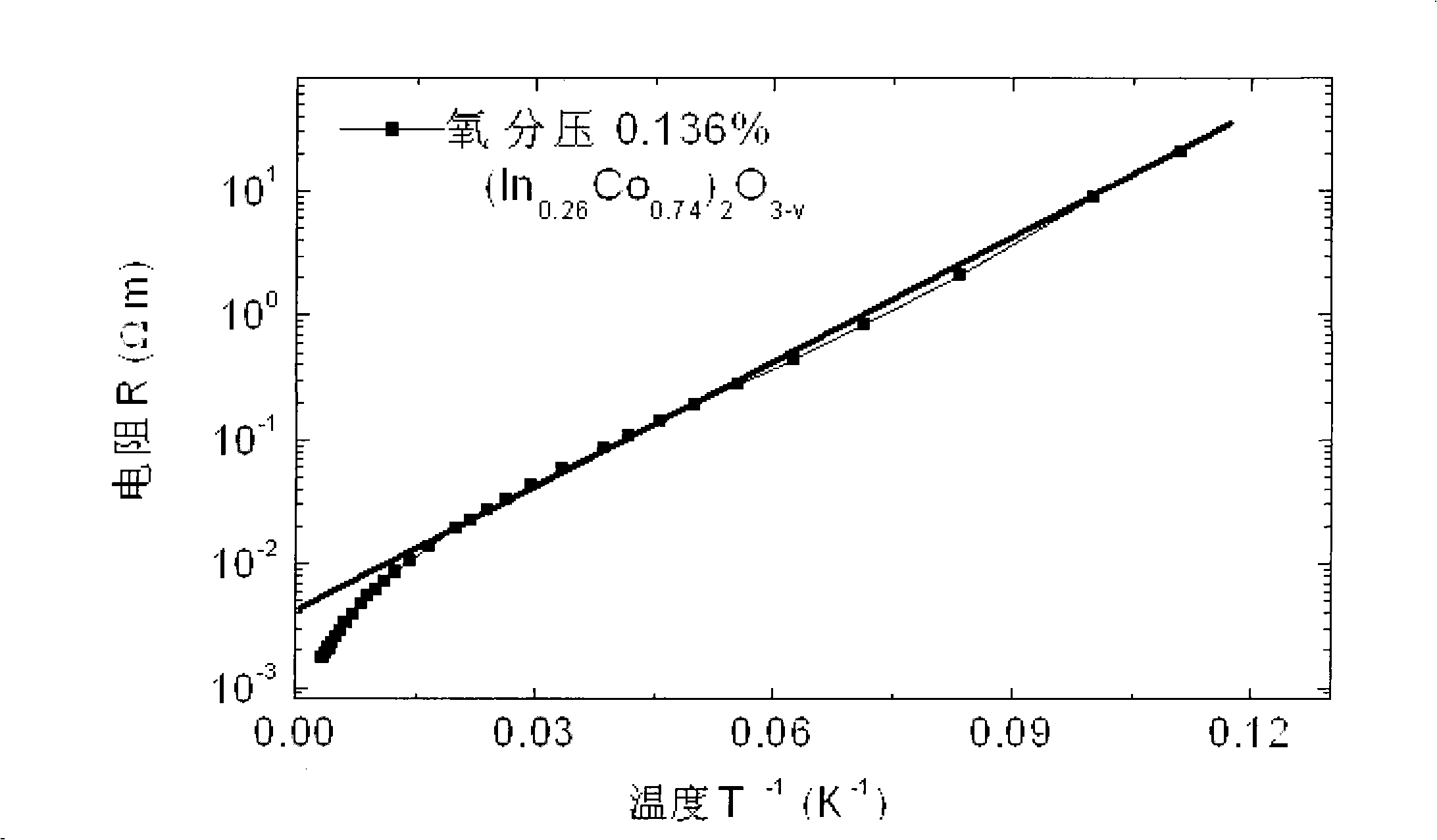

[0034] Embodiment 1: (In 0.26 co 0.74 ) 2 o 3-v The preparation of oxide magnetic semiconductor thin films and the control of their electrical transport properties use the method of magnetron sputtering, and the sputtering chamber is vacuumed to 5×10 -5 Pa, based on In with a purity of 99.99% or more 2 o 3 Ceramics and Co metal with a purity of more than 99.99% are used as targets, and In 2 o 3 Placed on the RF target, Co placed on the DC target. With high-purity Ar gas with a purity of more than 99.99% and O 2 The Ar gas with a molar ratio of 2% was used as the sputtering atmosphere, and the two gases were respectively entered into the gas mixing chamber through the gas mass flow meter, and after being thoroughly mixed uniformly in the gas mixing chamber, they entered the sputtering chamber. The pressure of the sputtering chamber was kept at 1Pa. The partial pressure of oxygen is controlled by a mass flow meter, and in this example, the partial pressures of oxygen ar...

Embodiment 2

[0037] Example 2: Sn 0.34 Fe 0.66 o 2-v Preparation of Oxide Magnetic Semiconductor Thin Films Controlling Their Electrical Transport Properties

[0038] Using the method of pulsed laser deposition, with (111) silicon single crystal as the substrate, SnO with a purity of more than 99.99% 2 Ceramics and Fe metal with a purity of more than 99.99% are used as targets, when vacuumed to 5×10 -5 Pa, through the gas mass flow meter into the oxygen, by adjusting the flow of oxygen to control the oxygen pressure in the vacuum chamber. In this example, the partial pressures of oxygen are 5×10 -5 Pa, 1×10 -5 Pa, 5×10 -4 Pa. When the system pressure is stabilized, start to deposit. On the (111) silicon single crystal substrate, a layer of 0.6nm SnO was alternately deposited 2 , a layer of 0.4nm Fe with an alternating period of 90.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com