Method for manufacturing high temperature uron commutative LiNbO3 optical waveguide

A technology of proton exchange and manufacturing method, which is applied in the direction of optical waveguide and light guide, can solve the problems of large dispersion of waveguide properties, weak proton diffusion ability, and short exchange time, and achieve the effects of reducing production costs, reducing losses, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The features of the present invention and other related features will be further described in detail below in conjunction with the accompanying drawings through embodiments, so as to facilitate the understanding of those skilled in the art:

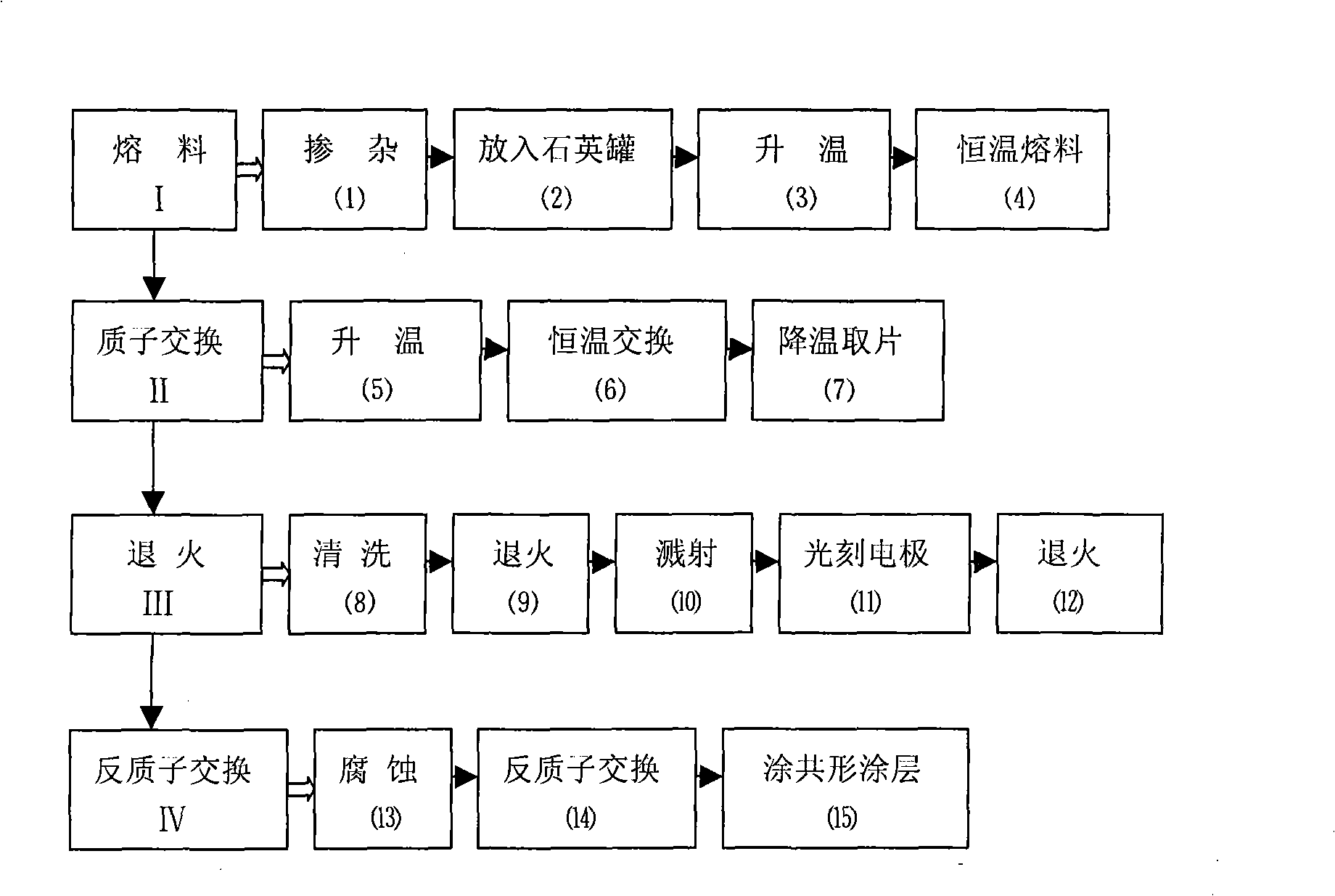

[0026] The specific implementation steps of this embodiment are as follows figure 1 As shown, the main process consists of four steps: melting material I, proton exchange II, annealing III, and antiproton exchange IV.

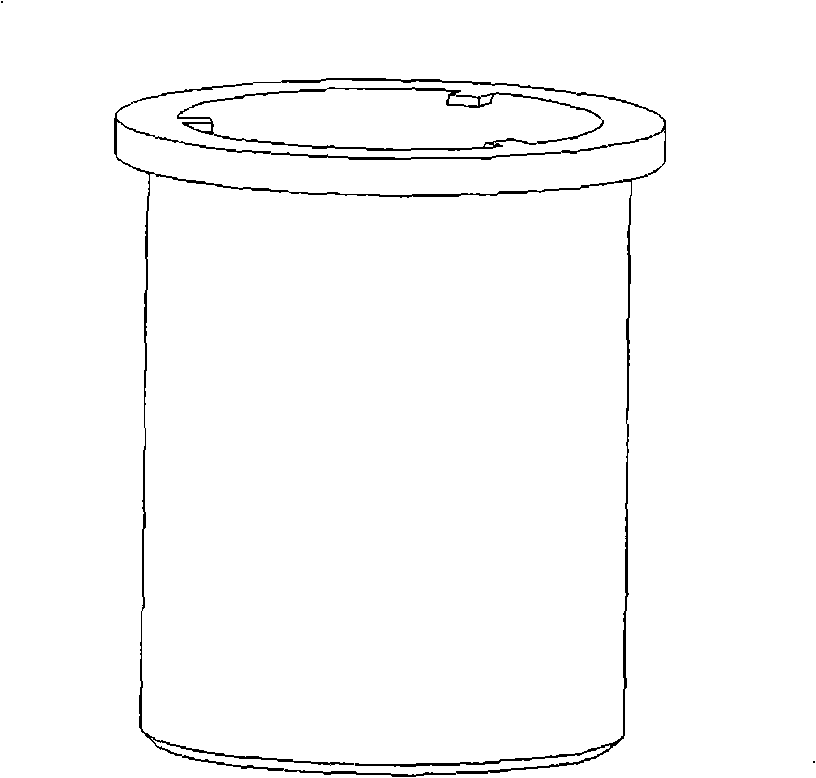

[0027] The melting material I process is to heat and react the mixed benzoic acid powder and lithium niobate powder to generate lithium benzoate, and then cool it to solidify it in the quartz jar. Its main purpose is to generate lithium benzoate and fully mix it with benzoic acid. The method of directly adding lithium benzoate is not adopted in the process, mainly because the purity of lithium benzoate produced on the market is not high, and the products vary greatly between different batches, which affects the sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com