High-efficiency corrosion resistant heat-transfer pipe

A technology of corrosion-resistant and heat-transfer tubes, applied in the field of heat-transfer tubes and high-efficiency corrosion-resistant heat-transfer tubes, can solve the problems of low thermal conductivity material fins, low efficiency and reduced heat transfer coefficient, and achieve the effect of saving material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

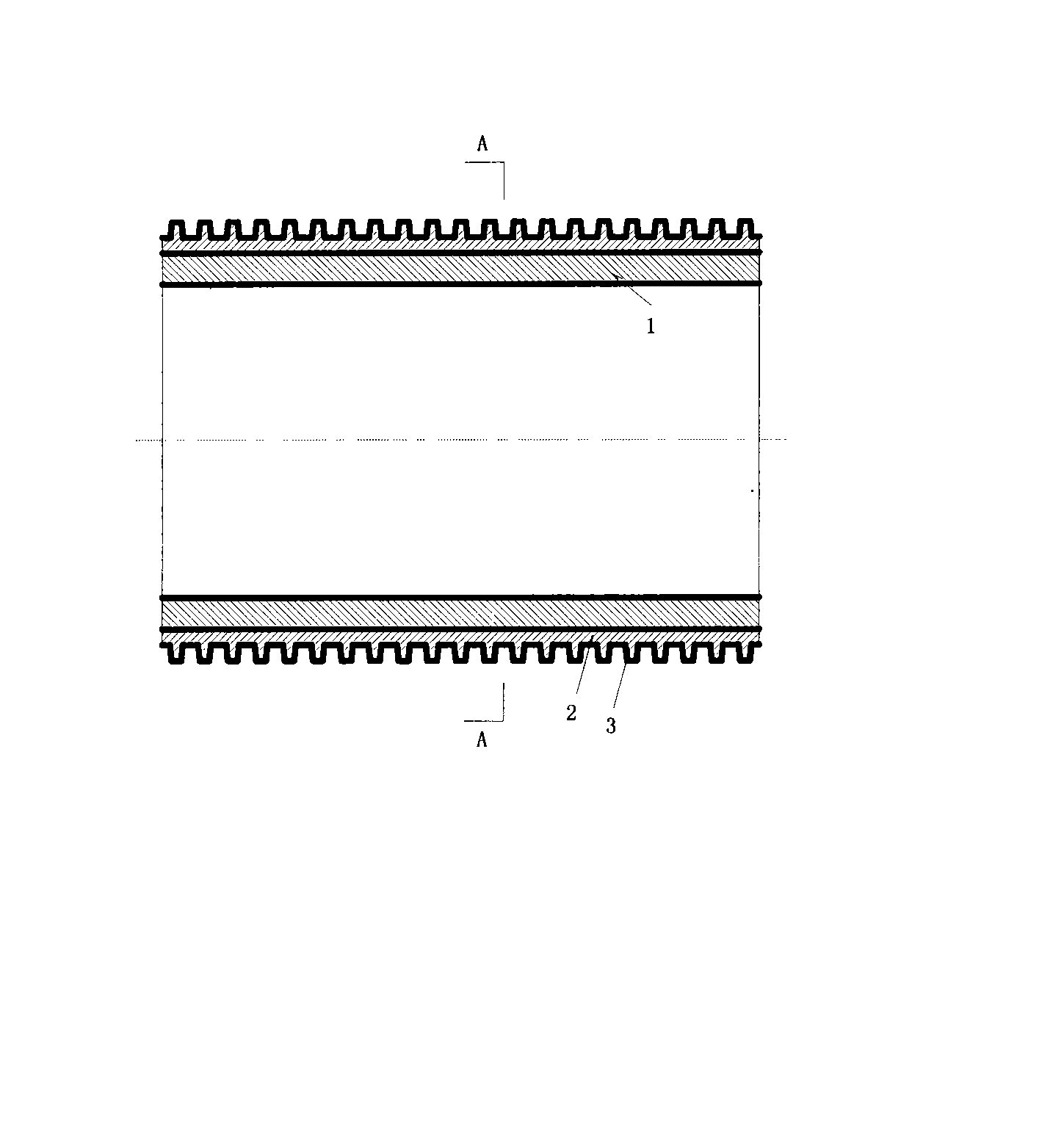

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0013] Referring to Figures 1 and 2, the high thermal conductivity material tube 2 is rolled outside the low thermal conductivity material tube 1, and the high thermal conductivity material tube 2 is processed into various types of fins 3. The two contact surfaces are polished in advance, and then the high thermal conductivity material tube 2 is processed into various types of fins 3. The heat-conducting material tube 2 is in close contact with the inner tube by stretching. The invention relates to a high-efficiency heat transfer tube which is corrosion-resistant and has a relatively high heat transfer coefficient. The corrosive fluid is still in contact with corrosion-resistant materials, and the outside of the tube is a material with a high thermal conductivity, which is processed into various types of fins, and the efficiency of the fins is very high, ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com