Activator for magnesium alloy welding

A technology of activating agent and magnesium alloy, which is applied in welding medium, welding equipment, welding equipment, etc., can solve the problems such as the magnesium alloy activating agent formula is not proposed, and achieve the advantages of reducing deformation, good weld formation, and reducing welding current Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] Active agent weight ratio is: TiO 2 58.6%, Cr 2 o 3 9.7%, MgO7.3%, MnO 2 12.7%, CaO11.7%, put the above components in the grinding equipment to fully grind, after drying and cooling, mix with acetone or alcohol and evenly coat or spray on the surface of the bead to be welded, the thickness of coating or spraying It is advisable to cover the original color of the base metal, the width is about 20mm, and the consumption of activator per meter of weld bead is about 0.5g, and the welding is performed after the acetone or alcohol volatilizes.

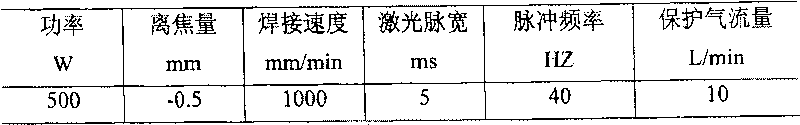

[0012] The welding specifications adopted for argon tungsten arc welding of magnesium alloy plates with a plate thickness of 6, 8, and 10 mm are:

[0013] plate thickness

[0014] When using this active agent, the depth of penetration is increased by 2 times. For the butt joint of magnesium alloys below 10mm, there is no need to open a bevel, and the straight edge is used for the butt joint without leaving gaps. It can be...

Embodiment 2

[0016] Active agent weight ratio is: TiO 2 40%, Cr 2 o 3 20%, MgO20%, MnO 2 10%, CaO10%, put the above components in the grinding equipment to fully grind, after drying and cooling, mix with acetone or alcohol and evenly coat or spray on the surface of the weld bead to be welded, the thickness of the coating or spraying can be It is advisable to cover the original color of the base metal, the width is about 20mm, and the consumption of activator per meter of weld bead is about 0.5g, and the welding is performed after the acetone or alcohol volatilizes. The welding specification is the same as in Example 1.

Embodiment 3

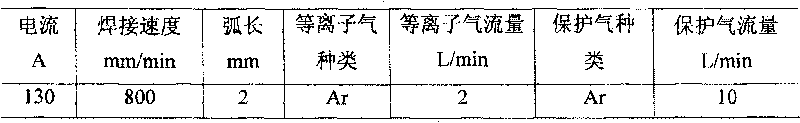

[0018] Active agent weight ratio is: TiO 2 70%, Cr 2 o 3 18%, MgO2%, MnO 2 5%, CaO5%, put the above components in the grinding equipment to fully grind, mix evenly, dry and cool, mix with acetone or alcohol and evenly coat or spray on the surface of the weld bead to be welded, coat or spray The thickness should be able to cover the original color of the base metal. The width is about 20mm. The consumption of activator per meter of weld bead is about 0.5g. After the acetone or alcohol volatilizes, it can be welded. Weld with 500WYAG laser, and there is no gap in the straight edge. Butt welding 2.5mm thick magnesium alloy plate, the welding specification is:

[0019]

[0020] Under such standard conditions, the penetration depth without active agent is only 0.8-1mm, and the penetration depth with active agent is 2.5mm, achieving complete penetration, and the penetration depth can be more than doubled after using the active agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com