Self-nano-structure diffusion welding technique for titanium alloy and stainless steel surface

A diffusion welding and self-nanometer technology, which is applied in welding equipment, metal processing equipment, surface polishing machine tools, etc., can solve the problems of inability to obtain tight welding, no intermediate layer metal, and low performance of welded joints, so as to shorten the welding time , reduce the pressure and temperature requirements, improve the effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

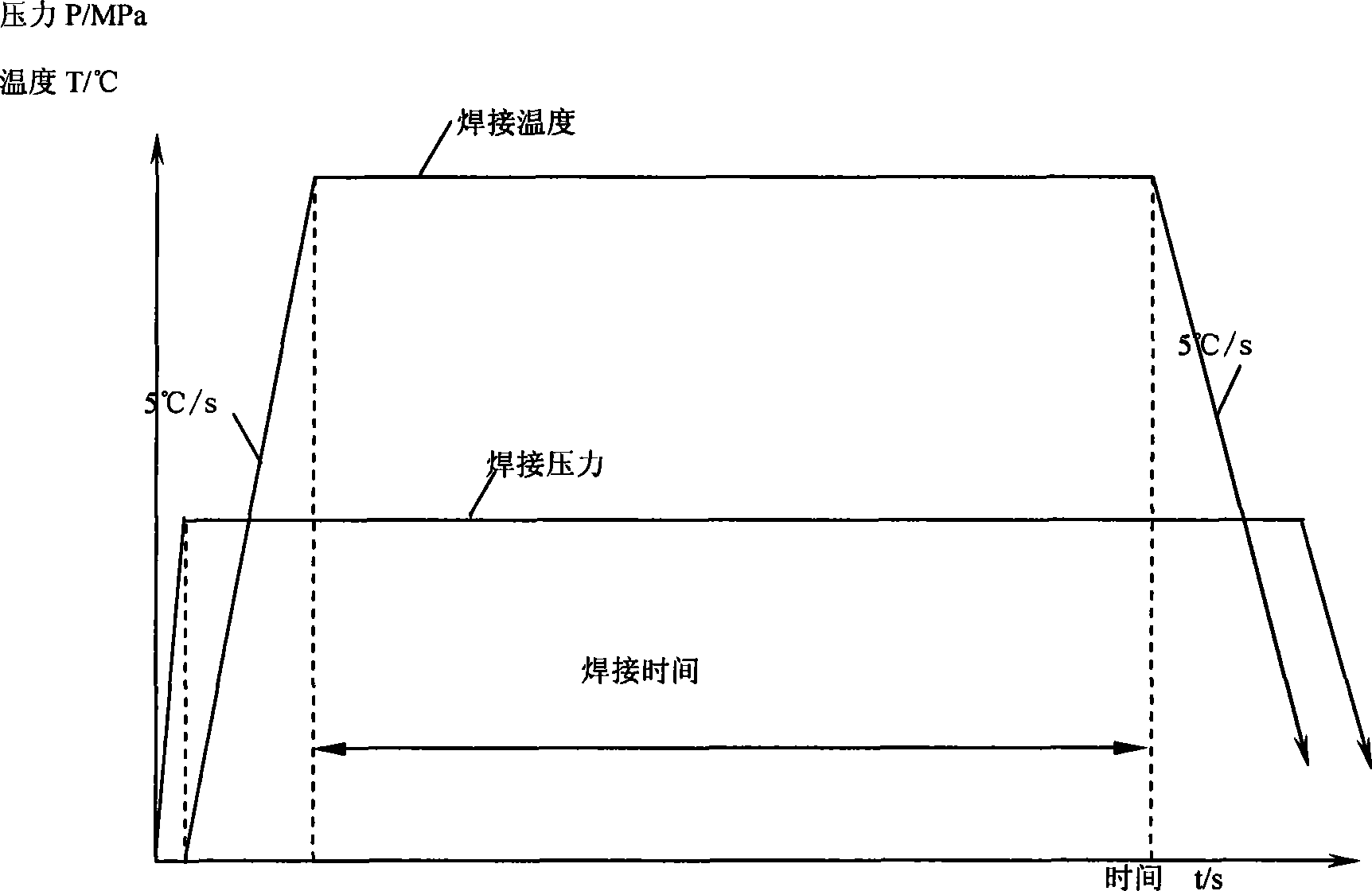

[0041] Diffusion welding process of titanium alloy and stainless steel surface self-nanoization

[0042] Step 1, preparation of raw materials, select Φ12.5mm×20mm TA1 titanium alloy and 00Cr18Ni10 stainless steel rods as the diffusion welding raw materials, use metallographic sandpaper to smooth the end faces of the raw materials and then polish them to obtain smooth end faces;

[0043] Step 2, surface self-nanometer treatment, put the raw material in step 1 into the shot blasting machine, use high-energy shot peening method to carry out surface self-nanometer treatment on the welding end face of the raw material, and suck the projectile with a diameter of 0.5mm into high pressure under the action of negative pressure The nozzle accelerates the projectile with a high-pressure airflow of 1MPa, impacts the end surface of the raw material to be welded, and the impact time is 1min. Finally, a 40μm deep nanocrystalline grain layer is obtained on the end surface of the raw material t...

Embodiment 2

[0047] Diffusion welding process of titanium alloy and stainless steel surface self-nanoization

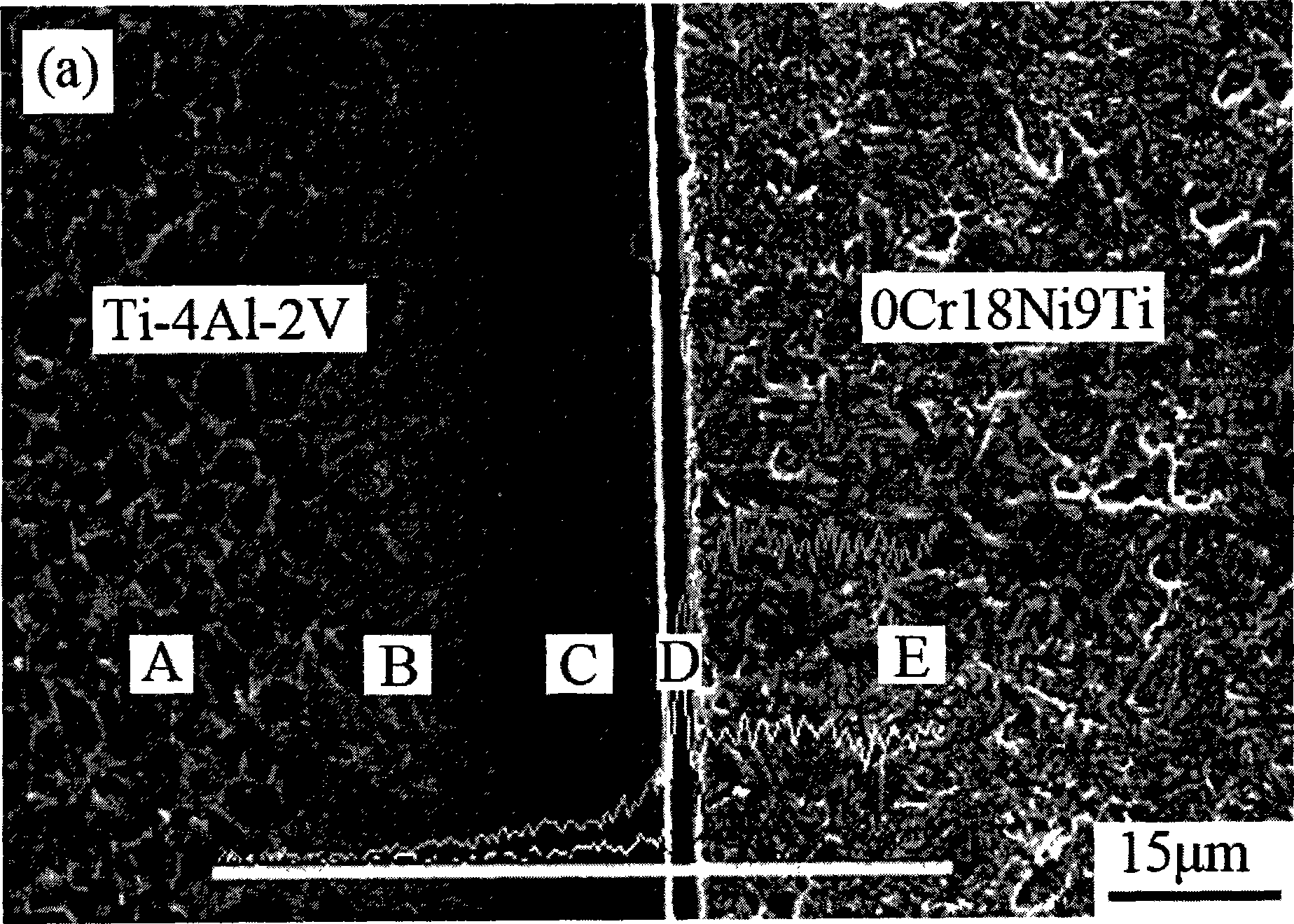

[0048] Step 1, preparation of raw materials, select Φ20mm×25mm near α-phase TA17 titanium alloy and 0Cr18Ni9Ti austenitic stainless steel rods as diffusion welding raw materials, use metallographic sandpaper to grind the end faces of raw materials to 1200# and perform mechanical polishing to obtain a smooth finish end face;

[0049] Step 2, surface self-nanometer treatment, put the raw material in step 1 into the shot blasting machine, use high-energy shot peening method to carry out surface self-nanometer treatment on the welding end face of the raw material, titanium alloy or stainless steel use cylindrical fixture in the shot peening process Clip the end to be treated. Inhale a projectile with a diameter of 5mm into a high-pressure nozzle under the action of negative pressure, accelerate the projectile with a high-pressure airflow of 1MPa, and impact the end surface of the raw...

Embodiment 3

[0053] Diffusion welding process of titanium alloy and stainless steel surface self-nanoization

[0054] Step 1, preparation of raw materials, select Φ12.5mm×30mm near α-phase TA17 titanium alloy and 0Cr18Ni9Ti austenitic stainless steel rods as diffusion welding raw materials, use metallographic sandpaper to smooth the end faces of raw materials and then polish them to obtain smooth end face;

[0055] Step 2, surface self-nanometerization treatment, put the raw materials in step 1 into the shot blasting machine, use high-energy shot peening method to carry out surface self-nanometerization treatment on the welding end face of the raw material, and suck the projectile with a diameter of 2.5mm into high pressure under the action of negative pressure The nozzle accelerates the projectile with a high-pressure airflow of 0.7MPa, impacts the end surface of the raw material to be welded, and the impact time is 15 minutes. Finally, a 70 μm deep nanocrystalline grain layer is obtained...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com