Short-flow production method of high-boron stainless steel plate

A technology of stainless steel plate and production method, applied in the direction of rolling force/roll gap control, temperature control, etc., can solve the problems of poor plastic deformation ability and difficult production, and achieve uniform boron content, high production efficiency, and diffusion coefficient. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

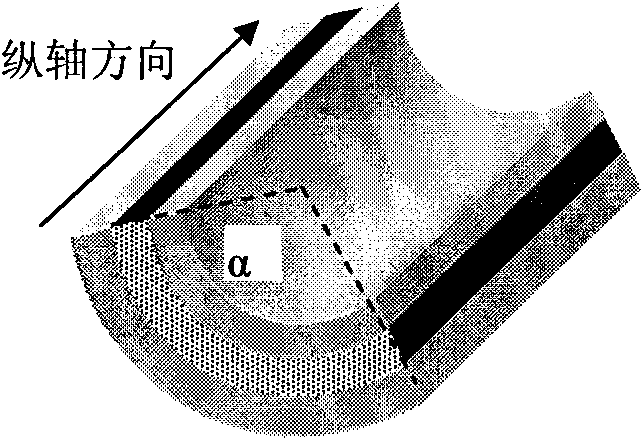

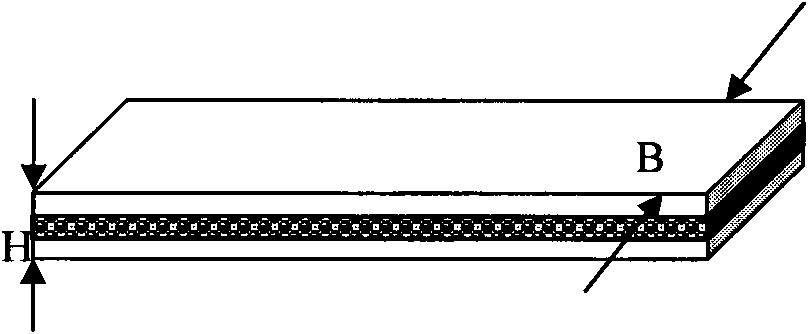

[0041] With boron content (C B ) 1.4% to 1.8%, and a high boron stainless steel plate with a thickness of 1mm is an example.

[0042] 1) Select the composite tube blank. You can choose a tube blank with an outer diameter of Φ630mm and a wall thickness of 50mm. After considering the amount of cutting, the outer diameter R3 = 310mm, and the inner diameter Ri = 270mm. The boron content in the inner layer metal is (Cm) 4.5±0.5%, and the boron content in the outer layer metal is (C') 0.1%. According to the formula (1), the full size of the composite tube blank can be estimated: R1=283.5 mm, R2 = 297.7 mm.

[0043] 2) Cast the outer layer of austenitic stainless steel first, the boron content is 0.1%, the casting temperature is between 1535±25°C, the thickness of the stainless steel is 20±2mm, and the centrifuge speed is gradually increased from 200 rpm to 300±100 rev / min. When the outer layer of stainless steel is initially solidified and the surface temperature is between 1400...

Embodiment 2

[0051] Take the high-boron stainless steel plate with a boron content (CB) of 2.5% to 3% and a thickness of 10mm as an example.

[0052] 1) Select the composite tube blank. You can choose a tube blank with an outer diameter of Φ710mm and a wall thickness of 60mm. After considering the amount of cutting, the outer diameter R3 = 350mm, and the inner diameter Ri = 300mm. The boron content in the inner layer metal is (Cm) 4.5±0.5%, and the boron content in the outer layer metal is (C') 0.1%. According to the formula (1), the full size of the composite tube blank can be estimated: R1=316.5 mm, R2 = 335.1 mm.

[0053] 2) According to the size of the tube blank selected in the previous step, refer to the casting process in the embodiment (1), directly cast a three-layer austenitic stainless steel composite tube blank, and cut the inner and outer layers by 5mm.

[0054] 3) Split the tube blank. Estimated according to formula (2), if the tube blank is evenly divided into parts, that...

Embodiment 3

[0063] Take the high-boron stainless steel plate with a boron content (CB) of 2.5% to 3% and a thickness of 3mm as an example.

[0064] Step 1)~step 4) all can refer to embodiment 2,

[0065] 5) Hot rolling the billet with a fan-shaped cross section, the rolling temperature is between 1180°C and 850°C, wherein:

[0066] ① The first to second passes are mainly to straighten the fan-shaped billet horizontally, the reduction is 10% to 20%, and the rolling start temperature should be kept at 1180°C to 1100°C;

[0067] ②The amount of deformation should be increased from the 3rd to the 10th pass, with a reduction of 15% to 30%, and the temperature should be kept above 950°C to fully break the as-cast structure.

[0068] ③ The reduction in the last 2 to 3 passes should be reduced and maintained at 10% to 15%, until the plate thickness reaches 3mm.

[0069] 6) Diffusion annealing is carried out under the protection of argon, and the hot-rolled plate is annealed in a resistance furna...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com