Roll collar roller capable of cyclic utilization and production method

A manufacturing method and technology of roll rings, applied in the direction of rolls, metal rolling, manufacturing tools, etc., can solve the problems of roll collapse and lack of large-scale promotion, and achieve good rolling effect, stable structure, and pollution-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

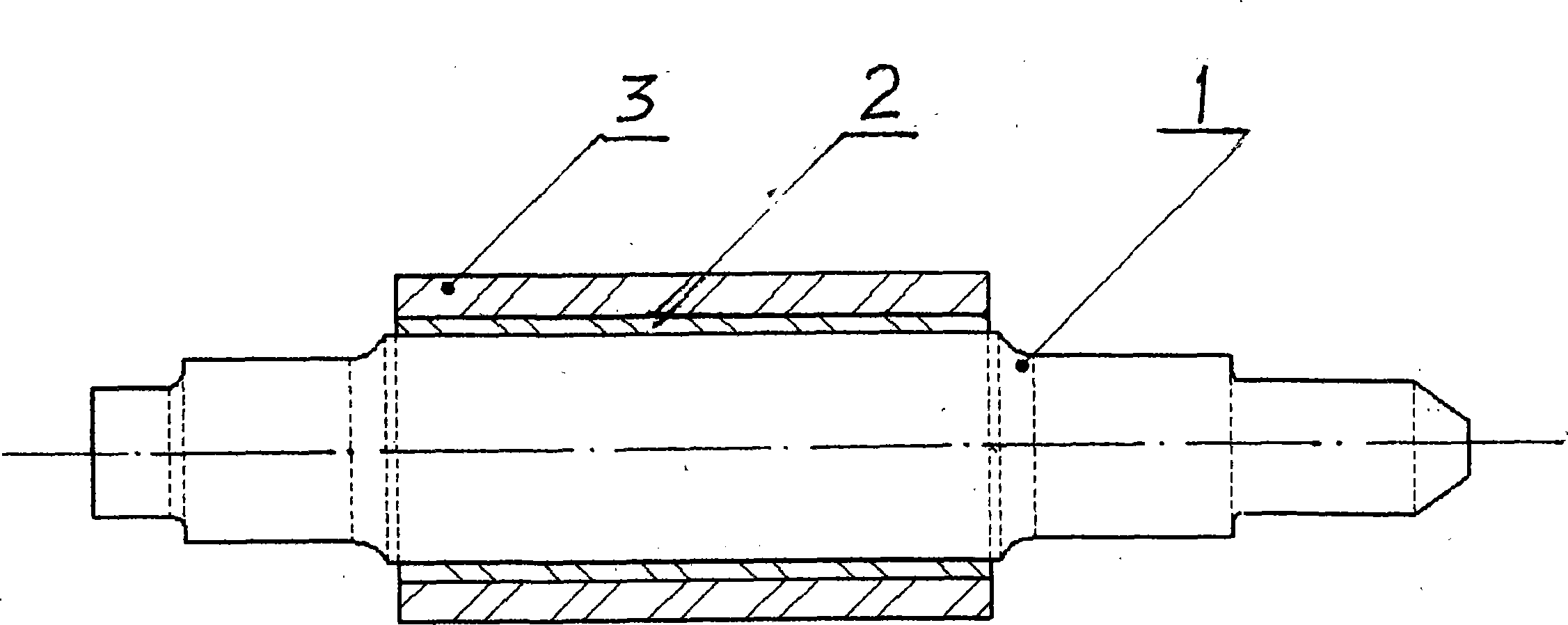

[0019] Embodiment 1, bar roll:

[0020] The wear-resistant outer ring 3 is made of high-boron alloy steel, the high-toughness inner ring 2 is made of Q195 seamless steel pipe, the mandrel 1 is made of scrapped integral rolls, and the high-boron alloy steel is melted into molten steel by an intermediate frequency furnace with a nominal capacity of 500 kg. 450kg of molten steel is tapped at a temperature of 1650°C, the temperature of the molten steel is 1520°C during casting, the inner ring 2 is preheated to 500°C, and the interference fit is H7 / s6. Used in the second bar factory of a certain unit, the steel passing capacity is more than twice that of the original roll, and the use is stable. No breakage phenomenon;

Embodiment 2

[0021] Embodiment 2 strip steel roll:

[0022] The wear-resistant outer ring 3 is made of cast high-carbon high-speed steel, the high-toughness inner ring 2 is made of Q195 seamless steel pipe, the mandrel 1 is made of scrapped integral rolls, and the cast high-carbon high-speed steel is melted into steel by an intermediate frequency furnace with a nominal capacity of 500 kg. When the temperature of 350 kg of molten steel reaches 1650°C, the steel is tapped, the temperature of molten steel is 1540°C during pouring, the inner ring 2 is preheated to 300°C, and the interference fit is H7 / s6. Used in a steel factory, the amount of passing steel is more than three times higher than that of the original roll, and the use is stable without any damage.

Embodiment 3

[0023] Embodiment 3, profile roll:

[0024] The wear-resistant outer ring 3 is made of high chromium cast iron, the inner ring 2 of high toughness is made of Q195 seamless steel pipe, and the mandrel 1 is made of scrapped integral roller. Melt the high chromium cast iron into molten steel with an intermediate frequency furnace with a nominal capacity of 1,500 kg. When the temperature of 1,200 kg of molten steel reaches 1,600°C, the steel is tapped. The temperature of the molten steel is 1,490°C during casting, and the inner ring 2 is preheated to 800°C. Choose H7 / s6 together. Used in a profile factory, the amount of passing steel is more than twice that of the original roll, and the use is stable without any damage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com