Oxide heat insulation layer for reducing phase-change memory cell power consumption and implementation method thereof

A technology of phase change memory and implementation method, which is applied in the field of microelectronics nanomaterials and device preparation, and can solve problems such as poor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

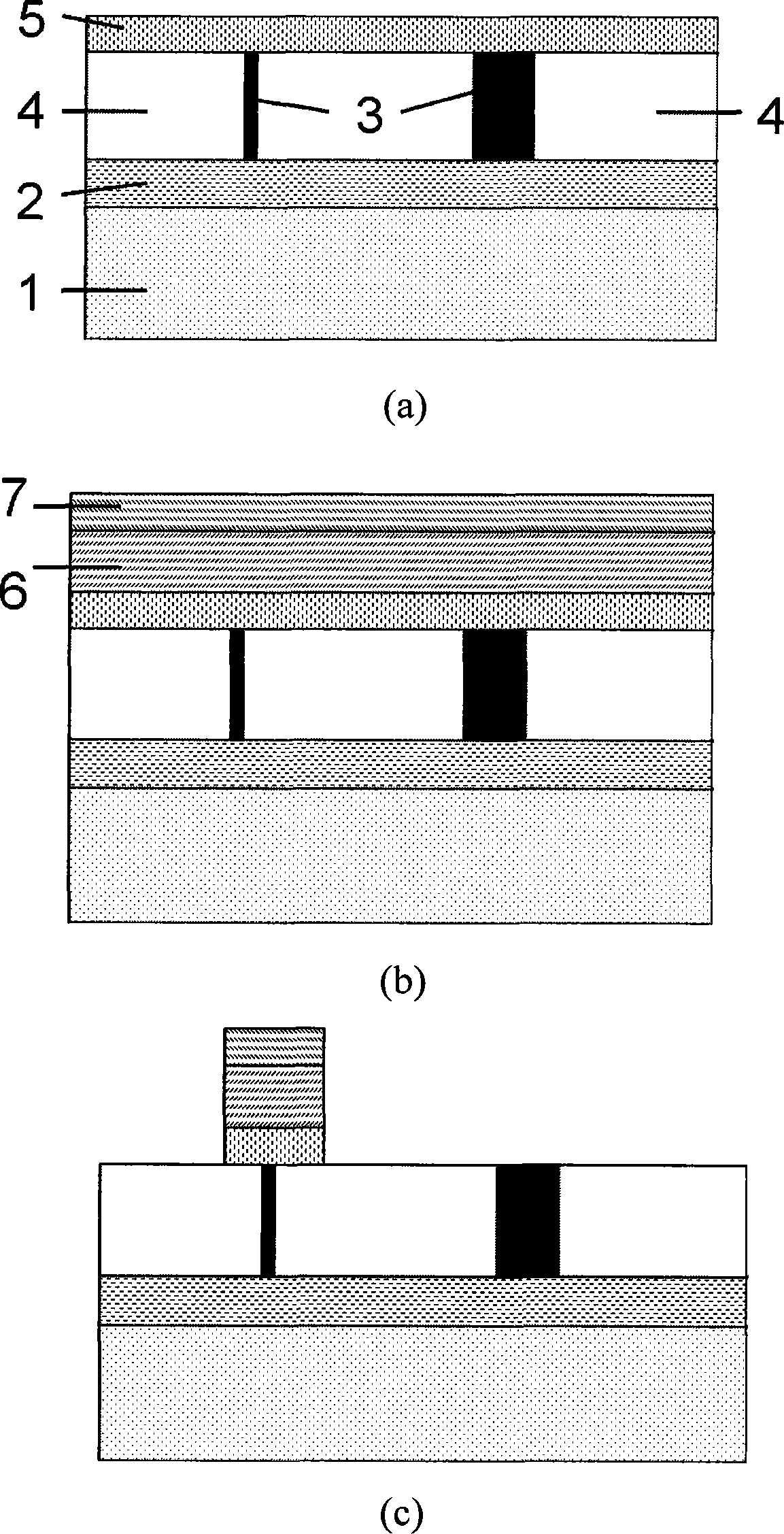

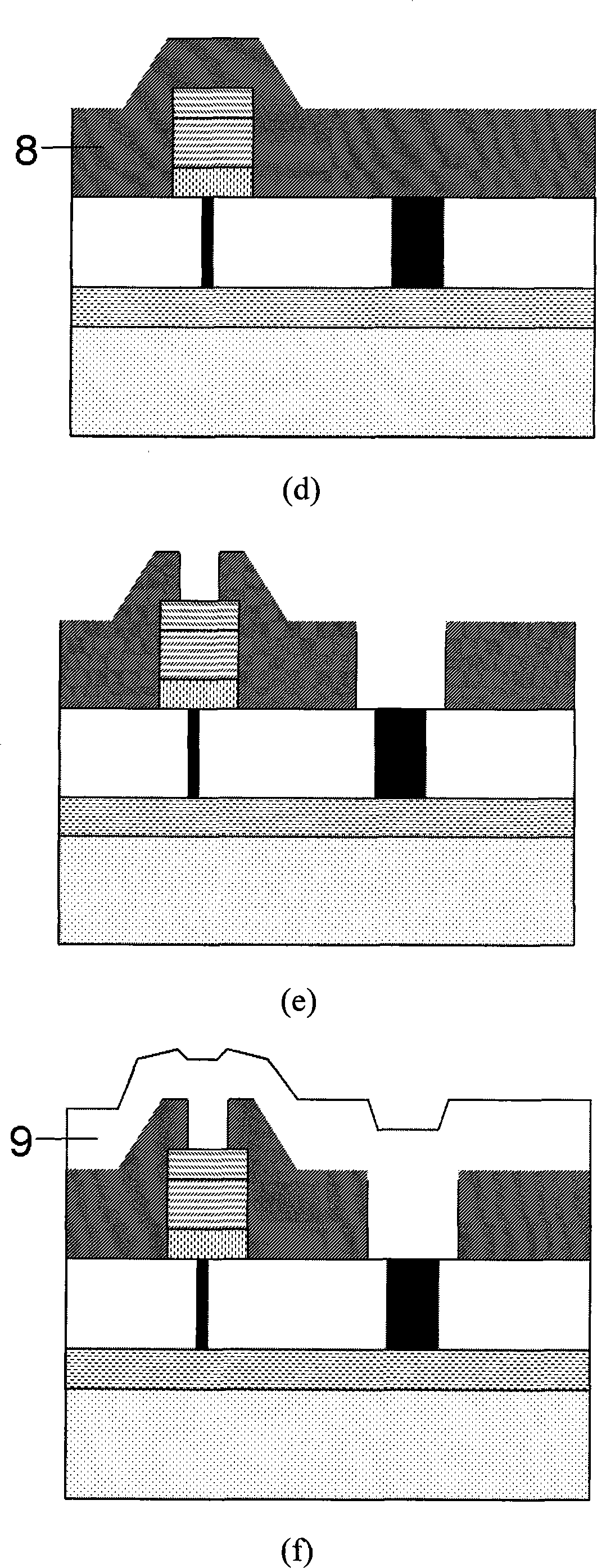

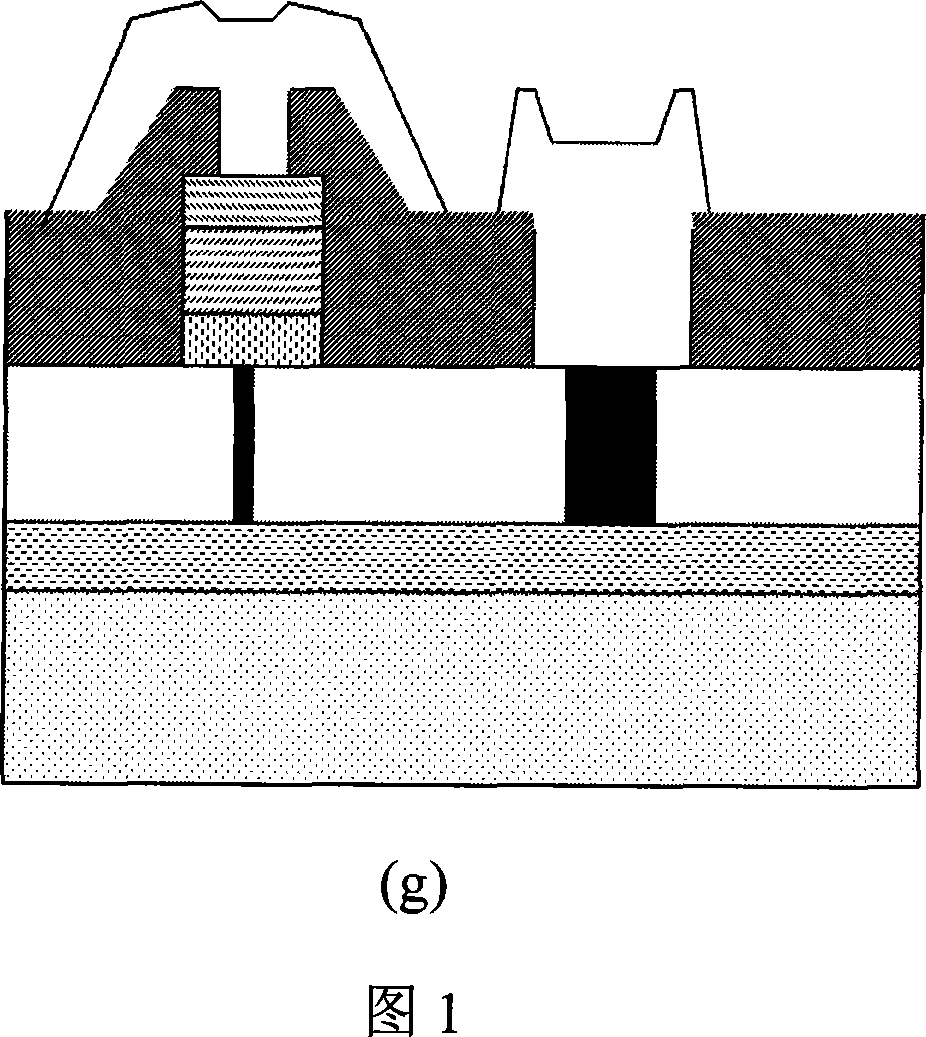

[0032] (1) Use acetone and alcohol solution to clean the substrate for 3 minutes each under the action of ultrasonic waves, then bake at 120°C for 20 minutes, and then deposit the heat-shielding layer oxide material on the substrate by magnetron sputtering Metal element material with a thickness of 4-5nm and a background vacuum of 4×10 during sputtering -6 Torr, the vacuum is 0.18Pa during sputtering, and then oxidized at 580°C for 10 minutes in a high-purity oxygen (>99.995%) atmosphere. Insulation layer material is TiO 2 Wait;

[0033] (2) Use magnetron sputtering method to deposit chalcogenide compound thin film layer 200nm and TiN thin film layer 20nm successively on the oxide insulation layer; the background vacuum is 4×10 during sputtering -6 Torr, the vacuum during sputtering is 0.16Pa and 0.40Pa, and the sputtering power is 200W and 400W respectively; (Figure 1, b)

[0034] (3) Use ultraviolet exposure photolithography to etch a square with a side length of 3-5 μm, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com