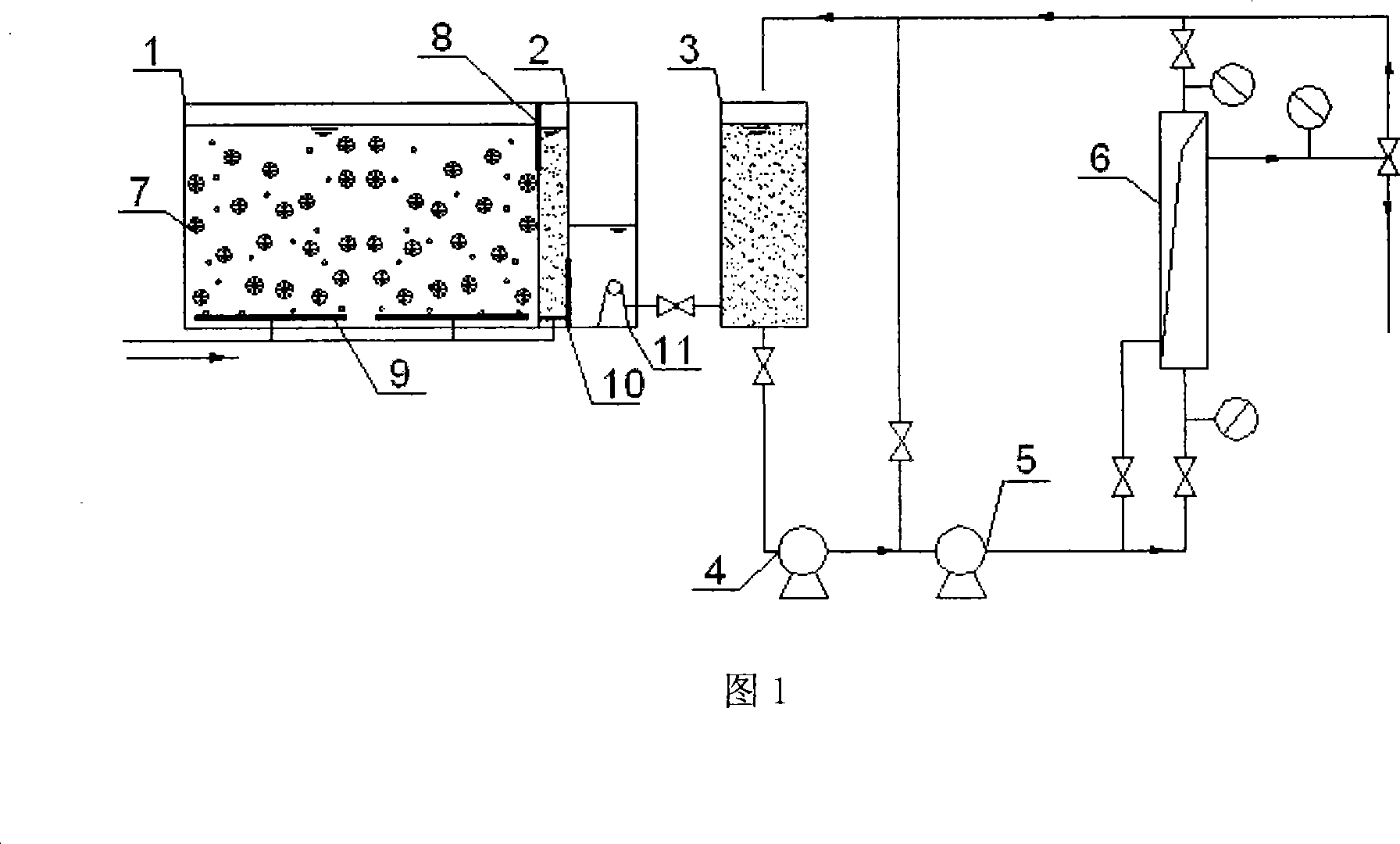

Two-stage dynamic membrane filtering method for printing and dyeing wastewater recycling

A printing and dyeing wastewater and filtration method technology, applied in the direction of filtration separation, separation method, chemical instrument and method, etc., can solve the problems of high operating cost, inconvenient operation and maintenance, etc., and achieve the effect of convenient operation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] After the printing and dyeing wastewater of a printing and dyeing factory undergoes biochemical + physical chemical treatment, the effluent reaches the first-level discharge standard of GB4287-92. The main indicators of effluent water quality are: COD3 / d The waste water treatment station can only meet the total requirement if it is reused. The effective volume of biological aerated filter is 25m 3 , using Φ20mm porous spherical suspension filler, 600-mesh filter cloth at the weir in the outlet tank, the primary dynamic membrane material is activated carbon powder with an average particle size of 0.1mm, and the average pressure difference at the water outlet is about 1m. An aeration pipe is installed under the filter cloth, and backwashing can be carried out by combining water and air. The inorganic ceramic membrane tube used in the microfiltration stage is a single-hole tube with an inner diameter of 11mm and a length of 1100mm. It adopts internal pressure cross-flow f...

Embodiment 2

[0026] The effluent water quality of the printing and dyeing desizing wastewater treatment system of a printing and dyeing factory meets the first-level discharge standard of GB4287-92. In order to reuse it in the desizing stage of the production process, the daily treatment capacity is 250m 3 / d depth processing device. The effective volume of biological aerated filter is 80m 3 , using microporous aeration, the dissolved oxygen in the pool is greater than 4mg / L, anthracite is used as the filter material, and the filling rate is greater than 50%. The lower part enters the upper part of the water, and the weir in the outlet tank has a 600-mesh filter cloth. The first-stage dynamic membrane material is diatomite with an average particle size of 0.1mm, and the average pressure difference at the outlet is about 1m. An aeration pipe is installed under the filter cloth, and backwashing can be carried out by combining water and air. The inorganic ceramic membrane tube used in the m...

Embodiment 3

[0028] After the wastewater treatment of a knitting printing and dyeing factory is cleaned and diverted, the main indicators of the water quality of the cleaned sewage are: COD3 / d Sewage treatment station, the effluent can be reused for the first stage of rinsing and miscellaneous domestic water. Water quality requirements ① Chromaticity (dilution factor) ≤ 10 ② Transparency (cm) ≥ 30 ③ pH 6.5~8.5 ④ Iron (mg / L) ≤ 0.1 ⑤ Manganese (mg / L) ≤ 0.1 ⑥ SS (mg / L) ≤ 10 ⑦ Total hardness (CaCO 3 Count, mg / L) ≤ 450. The effective volume of biological aerated filter is 80m 3 , using microporous aeration, the dissolved oxygen in the pool is greater than 4mg / L, ceramsite and activated carbon are used as filter materials, the upper part enters the water and the lower part exits, the weir in the outlet tank is 600 mesh filter cloth, and the first-class dynamic membrane material is an average particle size of 0.1 mm kaolin, the concentration of kaolin in the outlet tank is 5g / L, and the average...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com