2-methoxymethyl-4-aminophenol and its impurity highly effective liquid phase chromatography analytical method

A high-performance liquid chromatography, methoxymethyl technology, applied in the direction of analysis of materials, material separation, measurement devices, etc., to achieve the effect of simple and reliable analysis methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: the selection of high performance liquid chromatography condition

[0031] 1.1 Selection of mobile phase

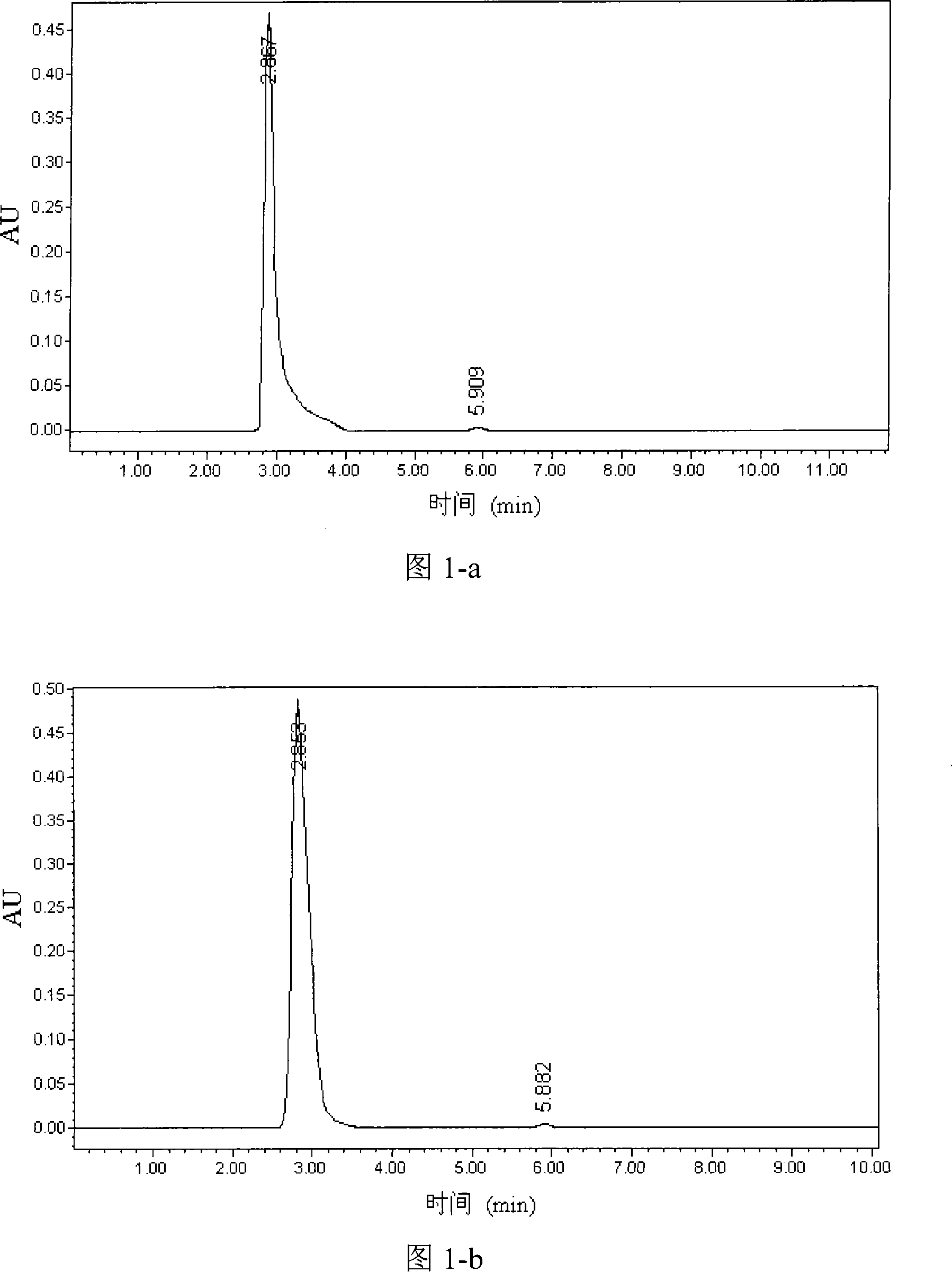

[0032] In the experiment, acetonitrile: water = 45: 5 5 was used for elution with equal flow ratio, and the separation of 2-methoxymethyl-4-aminophenol and impurities was good. However, due to the interaction between the amino and hydroxyl groups in 2-methoxymethyl-4-aminophenol and the residual silanol in the chromatographic column, the chromatographic peaks of 2-methoxymethyl-4-aminophenol have tailings. Phenomenon (Figure 1-a), affecting the accuracy of quantitative analysis of 2-methoxymethyl-4-aminophenol. Add phosphate 20mmol / l (NH 4 ) 2 HPO 4 The method of adjusting the pH value to 7.0 with phosphoric acid can eliminate the tailing phenomenon of chromatographic peaks (Fig. 1-b).

[0033] 1.2 Selection of detection wavelength

[0034] Continuously scan at 200-400nm with a diode array detector, 2-methoxymethyl-4-aminophenol has characterist...

Embodiment 2

[0037] Embodiment 2: the preparation of standard solution and sample solution

[0038] Accurately weigh 50.00mg of 2-methoxymethyl-4-aminophenol reference substance, place it in a 50ml volumetric flask, dissolve and dilute to the mark with mobile phase, shake well, and prepare 2-methoxymethyl-4-aminophenol with a concentration of 1.0mg / ml The standard stock solution of oxymethyl-4-aminophenol is gradually diluted to the required concentration when used.

[0039] Accurately weigh 25.00mg of 2-methoxymethyl-4-nitrophenol reference substance, place it in a 50ml volumetric flask, dissolve and dilute to the mark with mobile phase, shake well, and obtain 2-methoxymethyl-4-nitrophenol with a concentration of 0.5mg / ml The standard stock solution of oxymethyl-4-nitrophenol should be diluted step by step to the required concentration when used.

Embodiment 3

[0040] Embodiment 3: the making of standard curve

[0041] High performance liquid chromatography conditions: the chromatographic column is C 18 , 5 μ m, 150 × 4.6mm (I.D); The volume ratio of mobile phase composition: acetonitrile: phosphoric acid-phosphate buffered saline solution (PH7.0)=45: 55; Flow velocity 0.8ml / min; Column temperature 30 ℃; Detection wavelength 232nm . Take 10 μl of 2-methoxymethyl-4-aminophenol standard solution for injection, and plot the peak area against the concentration (Figure 3). 2-methoxymethyl-4-aminophenol is linear in the range of solution concentration 0.0001~1.0mg / ml, and the regression equation is:

[0042] A 2-甲氧甲基-4-氨基苯酚 =193754.33232+3.31341E7C, r=0.99997

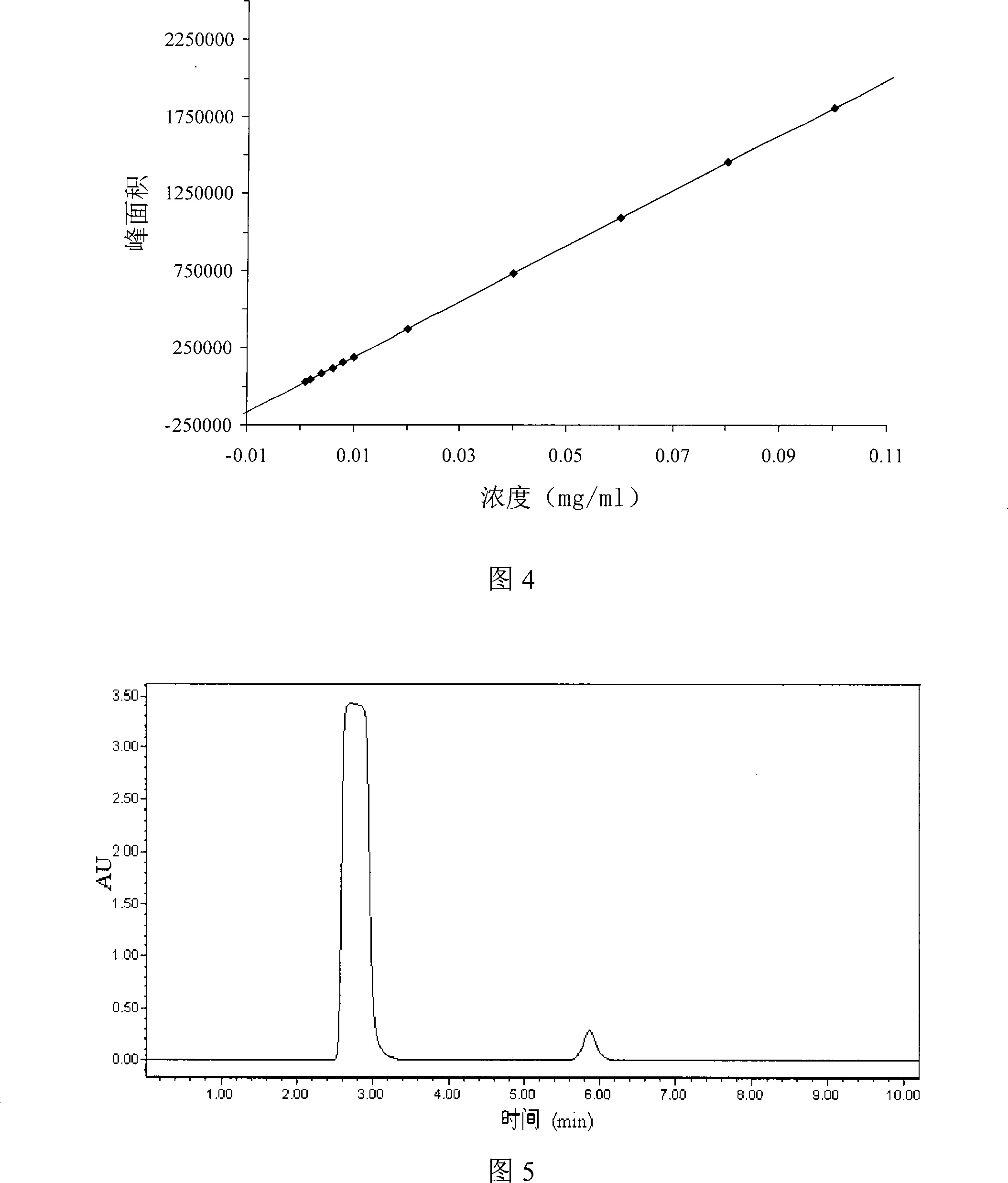

[0043] Take 10 μl of 2-methoxymethyl-4-nitrophenol standard solution for injection, and plot the peak area against the concentration (Figure 4). 2-methoxymethyl-4-nitrophenol is linear in the range of solution concentration of 0.0001~0.10mg / ml, and the regression equation is: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com