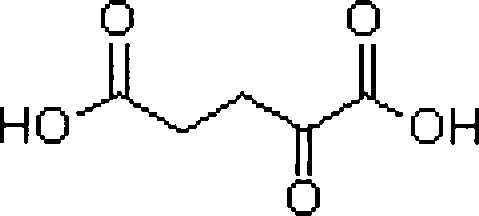

Alpha-ketoglutaric acid high yield bacterium, screening method thereof and production of alpha-ketoglutaric acid from the same by fermentation method

A technology of ketoglutaric acid and bacterial strains, which is applied in the field of bioengineering and can solve problems such as the lack of α-ketoglutaric acid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034]Sampling was taken from the soil near a certain oil refinery in Wuxi City, weighed 5g soil sample (wet weight), added to a conical flask containing 50mL thiamine-containing enrichment medium, cultivated at 30°C for 2- After 3 days, two more enrichments were carried out at a 10% inoculum size. Dilute the enriched culture with PBS (0.145mol / L sodium chloride, 0.01mol / L sodium phosphate aqueous solution) and spread it on CM, culture it at 30°C for 2-3 days, plant MM and SM correspondingly, selection cannot The strains that can grow on MM but can grow on SM, that is, thiamine auxotrophic strains, were further screened by fermentation. After culturing at 28°C and 200rpm for 3 days, the fermentation broth was taken and centrifuged, and the supernatant was spotted onto a thin silica gel chromatography plate, developed in a system with a volume ratio of benzene:ethyl acetate:acetic acid of 2:1:0.03, and bromophenol Blue color. The bacterial strains that retain the chromogenic ...

Embodiment 2

[0044] The physiological and biochemical characteristics of the screened WSH-Z06 strain were identified according to Microbial Taxonomy (see Tables 1, 2, and 3), and chromosomal DNA was extracted according to the method of refined molecular biology guidelines, with p1 and p2 as forward and Reverse primer, p1: 5'-ATCTGGTTGATCCTGCCAGT-3',

[0045] p2: 5'-GATCCTTCCGCAGGTTCACC-3',

[0046] The 18S rDNA gene was amplified by PCR, and Shanghai Sangon Bioengineering Co., Ltd. was entrusted to perform 18S rDNA sequencing. After obtaining some 18S rDNA gene fragments of this strain, the 18S rDNA gene sequences of related strains in GenBank were searched by BLAST on the NCBI website, and carried out. Homology comparison, based on 18SrDNA sequence analysis and identification of physiological and biochemical characteristics, combined with the study of the growth and fermentation characteristics of the bacteria, it is considered to be a variant of Yarrowia lipolytica, named Yarrowia lipoly...

Embodiment 3

[0055] Inoculate the cultivated CCTCC NO: M207143 seeds with 10% inoculation amount into the fermentation medium containing different carbon sources such as glucose, sodium acetate, mannitol, ethanol, glycerol and the like with the same carbon concentration (32g / L), and ferment and cultivate The rest of the basic composition is: ammonium sulfate 3g / L, potassium dihydrogen phosphate 1g / L, magnesium sulfate heptahydrate 0.7g / L, sodium chloride 0.5g / L, dipotassium hydrogen phosphate 0.1g / L, thiamine 4μg / L L, the initial pH of the culture medium was 4.5, and 20 g / L of calcium carbonate was added after inoculation to adjust the pH. Fermentation was carried out at 28° C. and 200 rpm for 90 h, and the content of α-ketoglutaric acid in the fermentation liquid was determined by HPLC. The results show that when using glycerol as a carbon source for fermentation, it is obviously better than other types of carbon sources (the concentration of 32g / L carbon source converted into glycerol is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com