Halogen-containing diphosphate or preparation method of halogen-containing diphosphorous acid ester

A technology of halogen-containing diphosphite and halogen-containing diphosphate, which is applied in the field of preparation of halogen-containing diphosphate or halogen-containing diphosphite, and can solve problems such as difficult product quality assurance, serious environmental pollution, and difficult control of conditions , to achieve the effect of low production cost, good color and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

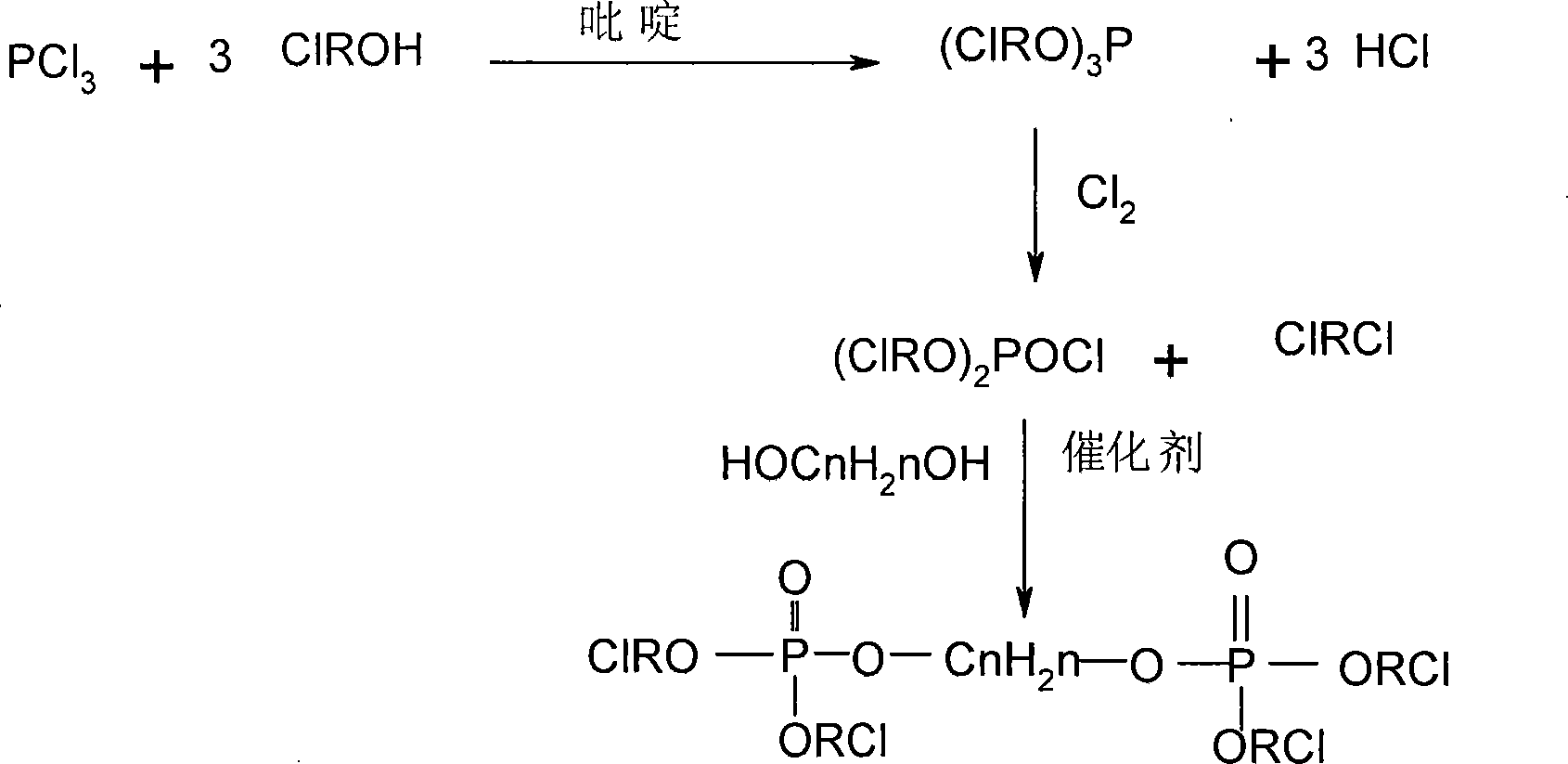

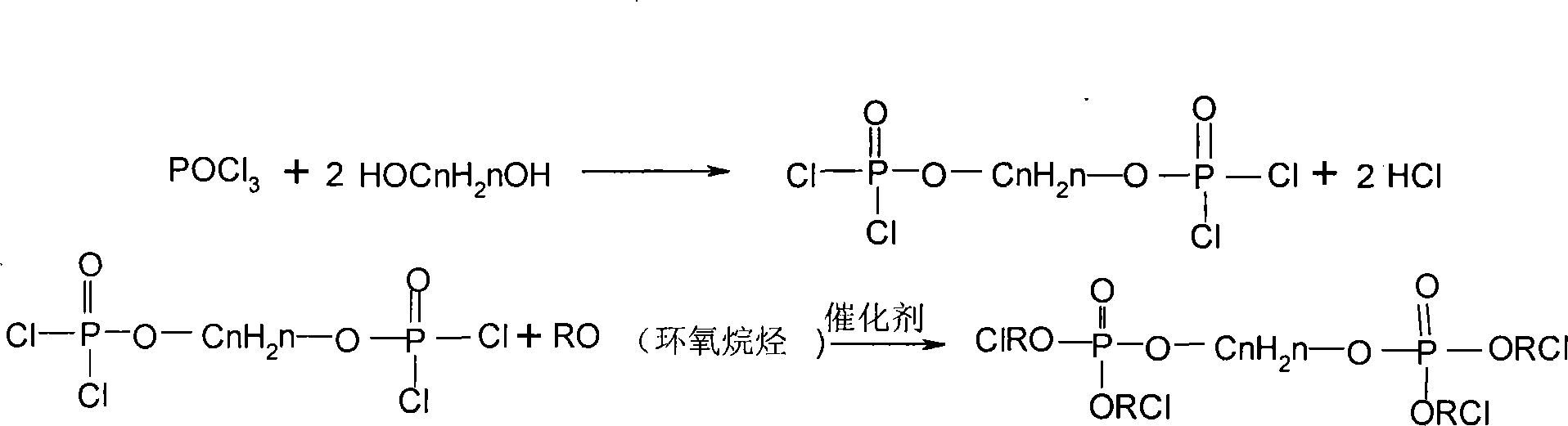

Method used

Image

Examples

Embodiment 1

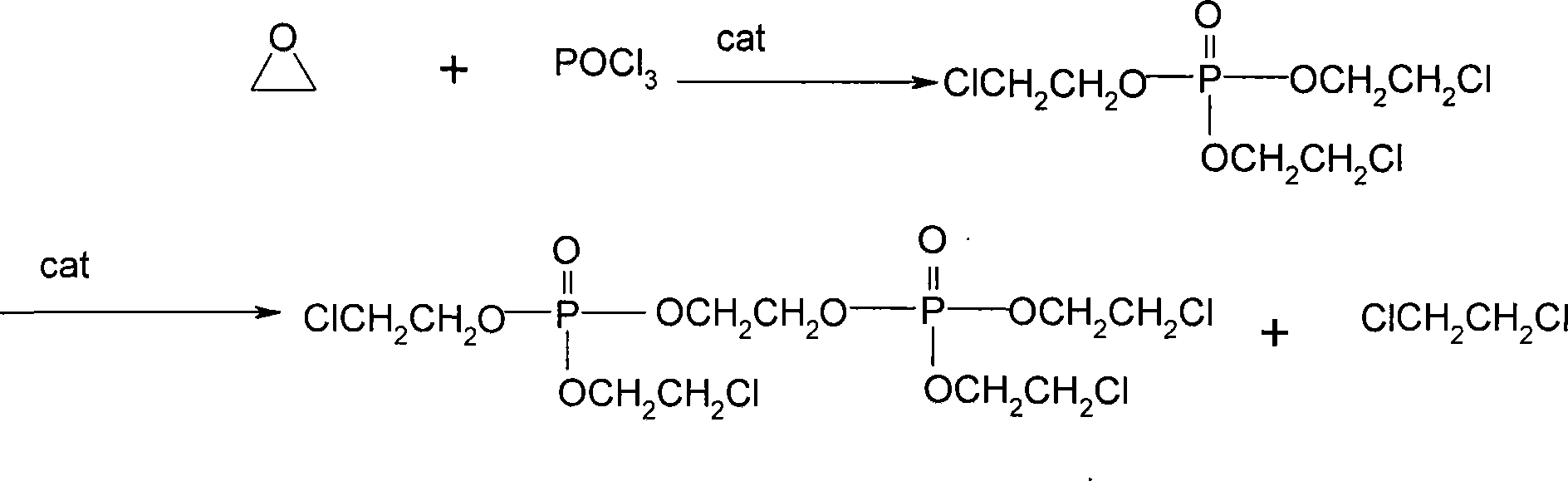

[0035] Add POCl 3 153.3g, catalyst aluminum isopropoxide 1.6g. Turn on the condensed water, stir, heat up to 40°C and start to pass Through 145g, passed through in 6-7 hours, and the temperature was controlled at 50-60°C. After passing through, keep it warm at about 60°C for 2 hours, and remove unreacted After filtration, 273.9 g of a colorless and transparent product tris(β-chloroethyl)phosphate (TCEP) was obtained, with a yield of 96.0%. The catalyst aluminum isopropoxide is recovered and reused.

[0036] Take the above TCEP 80.0g, anhydrous Na 2 CO 3 0.8g was added to a 150ml three-necked flask equipped with a magnetic stirrer and a thermometer, heated and stirred, heated to 185°C, 13.5g of dihaloalkane was distilled off, and 63.3g of colorless and transparent product diphosphate was obtained by filtration, with a yield of 95.6 %.

Embodiment 2

[0038] Add POCl 3 153.3g, catalyst solid superacid SO 4 2- / TiO 2 / La 3+ 2.1g. Turn on the condensed water, stir, heat up to 40°C and start to pass Through 145g, passed through in 6-7 hours, and the temperature was controlled at 50-60°C. After passing through, keep it warm at about 60°C for 2 hours, and remove unreacted After filtration, 273.9 g of a colorless and transparent product TCEP was obtained, with a yield of 96.0%. Catalyst solid superacid SO 4 2- / TiO 2 / La 3+ Recycle and reuse.

[0039] Take 80.0g of TCEP and 0.8g of KOH, put them into a 150ml three-necked flask equipped with a magnetic stirrer and a thermometer, heat and stir, heat to 185°C, distill 13.3g of dihaloalkanes, and filter to obtain the colorless and transparent product diphosphate 62.2 g, yield 93.9%.

Embodiment 3

[0041] Add POCl 3 153.3g, catalyst anhydrous AlCl 3 2.0g. Turn on the condensed water, stir, heat up to 40°C and start to pass Through 145g, passed through in 6-7 hours, and the temperature was controlled at 50-60°C. After passing through, keep it warm at about 60°C for 2 hours, and remove unreacted After filtration, 270.5 g of a colorless and transparent product TCEP was obtained, with a yield of 94.8%. Catalyst anhydrous AlCl 3 Recycle and reuse.

[0042] Take TCEP 80.0g, anhydrous K 2 CO 3 0.8g was added to a 150ml three-necked flask equipped with a magnetic stirrer and a thermometer, heated and stirred, heated to 185°C, 13.5g of dihaloalkanes were distilled off, filtered to obtain 62.8g of colorless and transparent product diphosphate ester, yield 94.8 %.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com