Formulation of peachblow glass and manufacturing technology thereof

A preparation process and glass technology, which is applied in glass manufacturing equipment, glass furnace equipment, manufacturing tools, etc., can solve the problem of less golden red glass, achieve stable quality, adapt to industrial production, and simple production process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

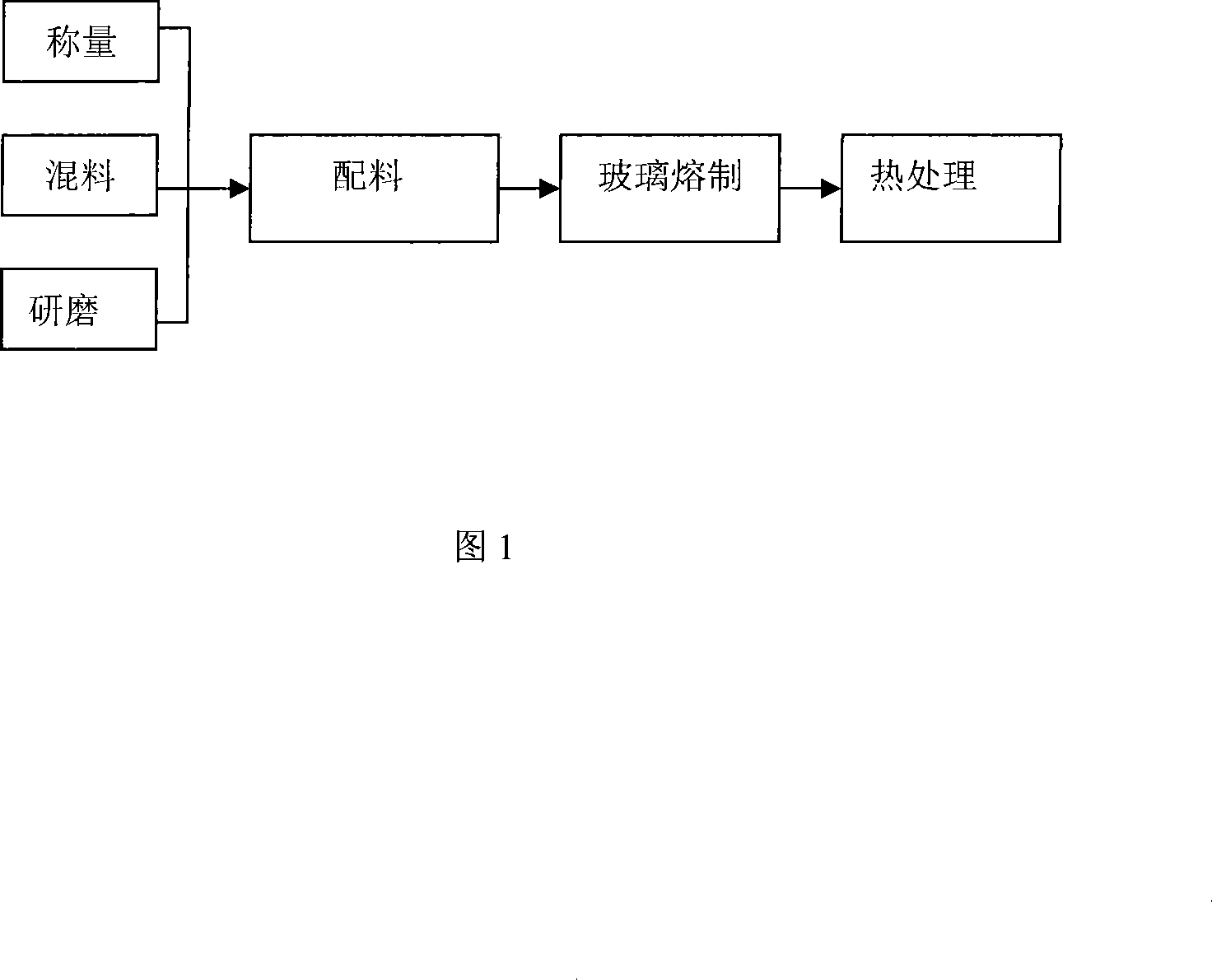

[0052] The main steps of the production process of this pink glass are as follows:

[0053] (1) The raw materials are proportioned according to the following parts by weight: SiO 2 65.00 copies; Na 2 O 4.50 copies; K 2 O 12.15 copies; B 2 O 3 2.50 parts; PbO 15.60 parts; SnO 2 0.25 parts; Au 0.0075 parts.

[0054] (2) Mix the various raw materials uniformly according to the required proportions, and put them into the crucible for melting glass at 1200°C. The clarification temperature of the glass is controlled at 1400°C, and the clarification time is 4 hours. During the clarification of the glass, the glass is constantly stirred.

[0055] (3) After the glass is cast and formed, it is immediately put into an annealing furnace for annealing, and the annealing temperature is controlled to 470°C.

[0056] (4) Expose the prepared sample to ultraviolet light for 10 minutes, and keep the distance between the lamp and the sample 10 cm.

[0057] (5) Put the irradiated sample into a resista...

Embodiment 2

[0059] The difference from Example 1 is that the raw materials are proportioned according to the following weight parts:

[0060] SiO 2 70.06 copies; Na 2 O 17.32 parts; BaO 8.36 parts; PbO 2.60 parts; B 2 O3 0.50 parts; Sb 2 O 3 1.15 parts; Au 0.01 parts.

[0061] The difference from Example 1 is that the sample is exposed to ultraviolet light for 30 minutes, the heat treatment temperature is 600° C., and the heat treatment time is 60 minutes.

Embodiment 3

[0063] The difference from Example 1 is that the raw materials are proportioned according to the following parts by weight:

[0064] SiO 2 65 parts; Na 2 O 5 copies; K 2 O 14 parts; PbO 15.6 parts; Sb 2 O 3 0.40 parts; Au 0.01 parts.

[0065] The difference from Example 1 is that the sample is exposed to ultraviolet light for 3 hours, the heat treatment temperature is 650°C, and the heat treatment time is 60 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com