Silicon-containing composite material and its preparation method and application

A silicon composite material and content technology, which is applied in the treatment of dyed polymer organic compounds, structural parts, electrical components, etc., can solve problems such as increasing production costs, destroying product coating structures, and affecting the electrochemical performance of composite materials, and achieving environmental protection. The effects of less pollution, simplified production process, and excellent electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] According to the preparation method of the silicon-containing composite material provided by the present invention, in order to make the polymerization reaction more uniform and the conductive polymer to coat the surface of the graphite particles more uniformly, the polymerization reaction and doping are preferably performed in the conductive polymer precursor. carried out in solution. The solution of the conductive polymer precursor contains an organic polymer precursor, an inorganic dopant and a solvent, and the concentration of the organic polymer precursor in the solution may be 0.1-10% by weight, preferably 1-5% by weight. The organic polymer precursor is a monomer substance that can act with an inorganic dopant to form a conductive polymer after polymerization. The organic polymer precursor can be, for example, one or more of aniline, pyrrole, thiophene, p-phenylenediamine, 3-butylthiophene, and benzene. Since aniline raw materials are cheap and easy to obtain, t...

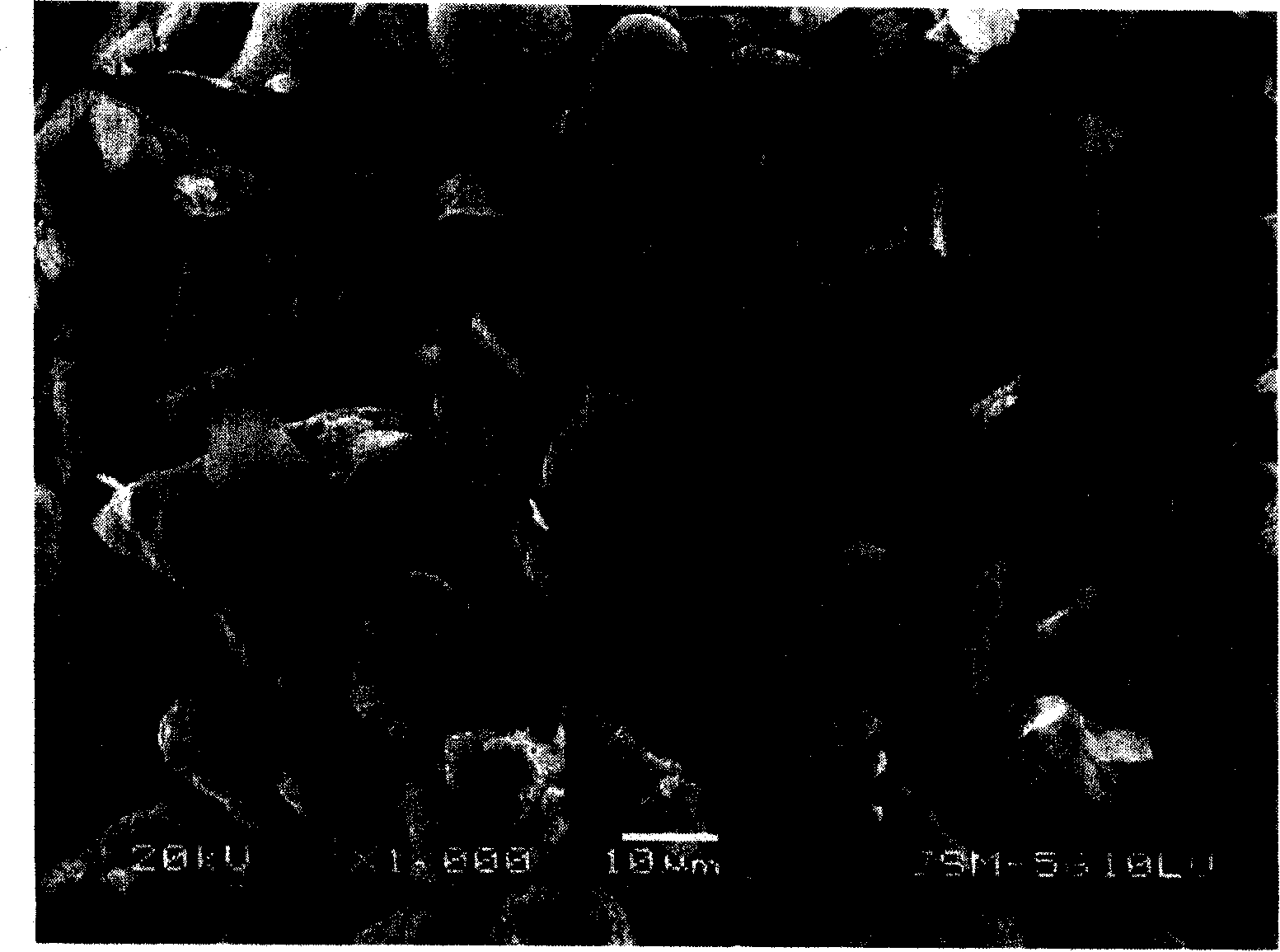

Embodiment 1

[0039] This example is used to illustrate the silicon-containing composite material provided by the present invention and the preparation method thereof.

[0040] 0.5 g of nano-silicon (particle diameter of 20-50 nanometers) and 0.5 g of polyvinylpyrrolidone were added to 100 ml of a hydrochloric acid solution with a concentration of 1 mol / L, and the nano-silicon was uniformly dispersed by magnetic stirring. Then add 9.5 grams of artificial graphite (average particle diameter D 50 = 20.75 microns, crystallite spacing d 002 0.33688 nm), stir well. Then add 0.7 g of aniline, continue magnetic stirring for 30 minutes, and add 50 ml of a 1 mol / L hydrochloric acid solution containing 1.84 g of ammonium persulfate to the mixture dropwise to initiate the polymerization of aniline monomers, and the dropwise addition is completed in 1 hour. After the dropwise addition was completed, the mixture was filtered, washed, and dried at 80° C. after stirring for 3 hours to obtain blue-black ...

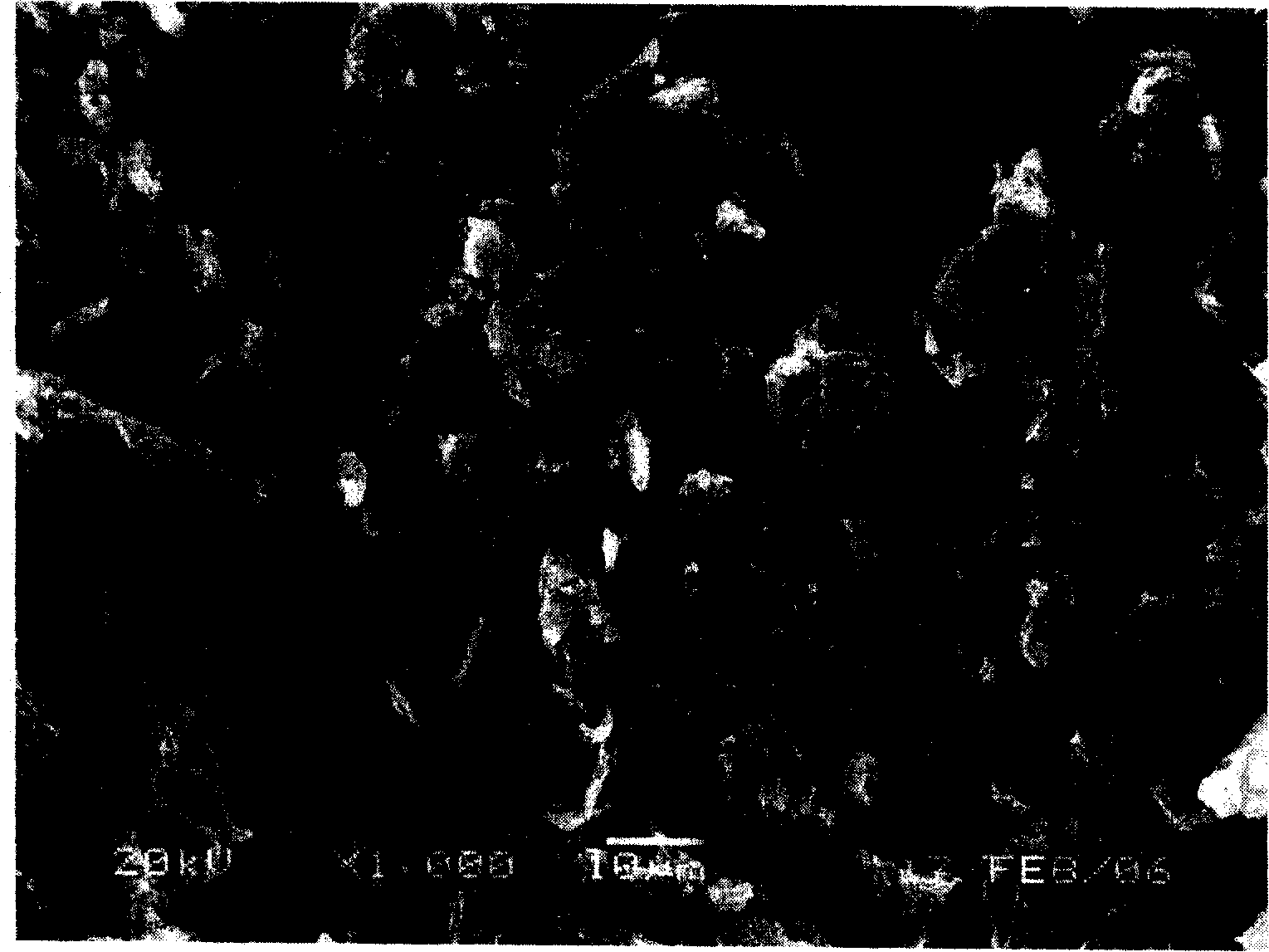

Embodiment 2

[0048] This example is used to illustrate the silicon-containing composite material provided by the present invention and the preparation method thereof.

[0049] 0.8 g of nano-silicon (particle diameter of 20-50 nanometers) and 0.8 g of polyvinylpyrrolidone were added to 100 ml of lithium chloride solution with a concentration of 1 mol / L, and the nano-silicon was uniformly dispersed by magnetic stirring. Then add 9.2 grams of artificial graphite (average particle diameter D 50 = 20.75 microns, crystallite spacing d 002 0.33688 nm), stir well. Then add 1.4 g of aniline, continue magnetic stirring for 30 minutes, add 50 ml of a 1 mol / L lithium chloride solution containing 3.68 g of ammonium persulfate into the mixture dropwise to initiate the polymerization of aniline monomer, and complete the dropwise addition in 1 hour. After the dropwise addition, the mixture was filtered, washed, and dried at 80° C. after stirring for 3 hours to obtain blue-black micropowder, that is, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com