Minute particle with needlelike surface and its manufacturing method

A manufacturing method and particle technology, which is applied in thin material processing, transportation and packaging, etc., can solve problems such as complex processes, and achieve the effect of expanding the surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0124] Hereinafter, although an Example and a reference example demonstrate this invention more concretely, this invention is not limited to these. Unless otherwise specified, "%" means "mass %".

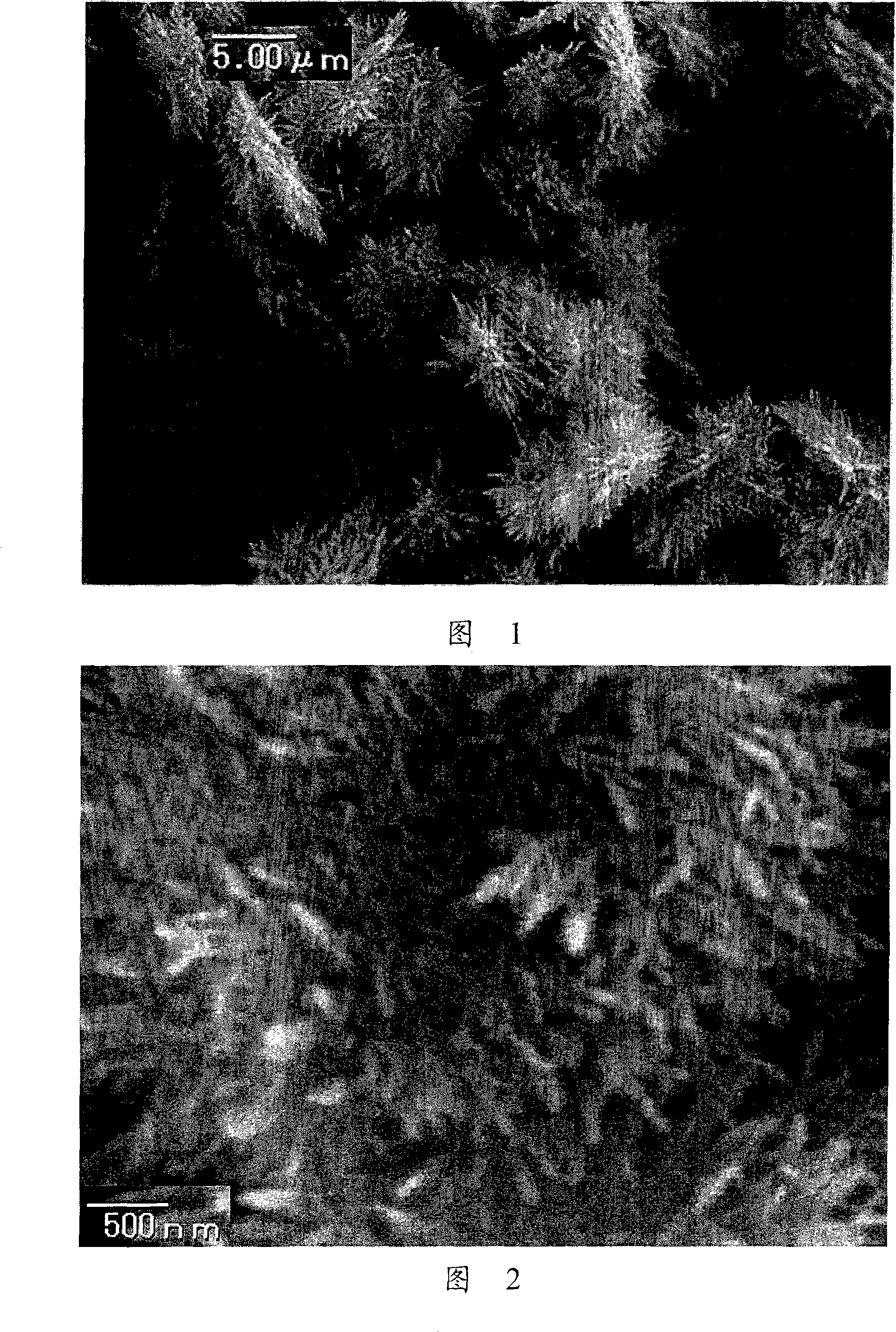

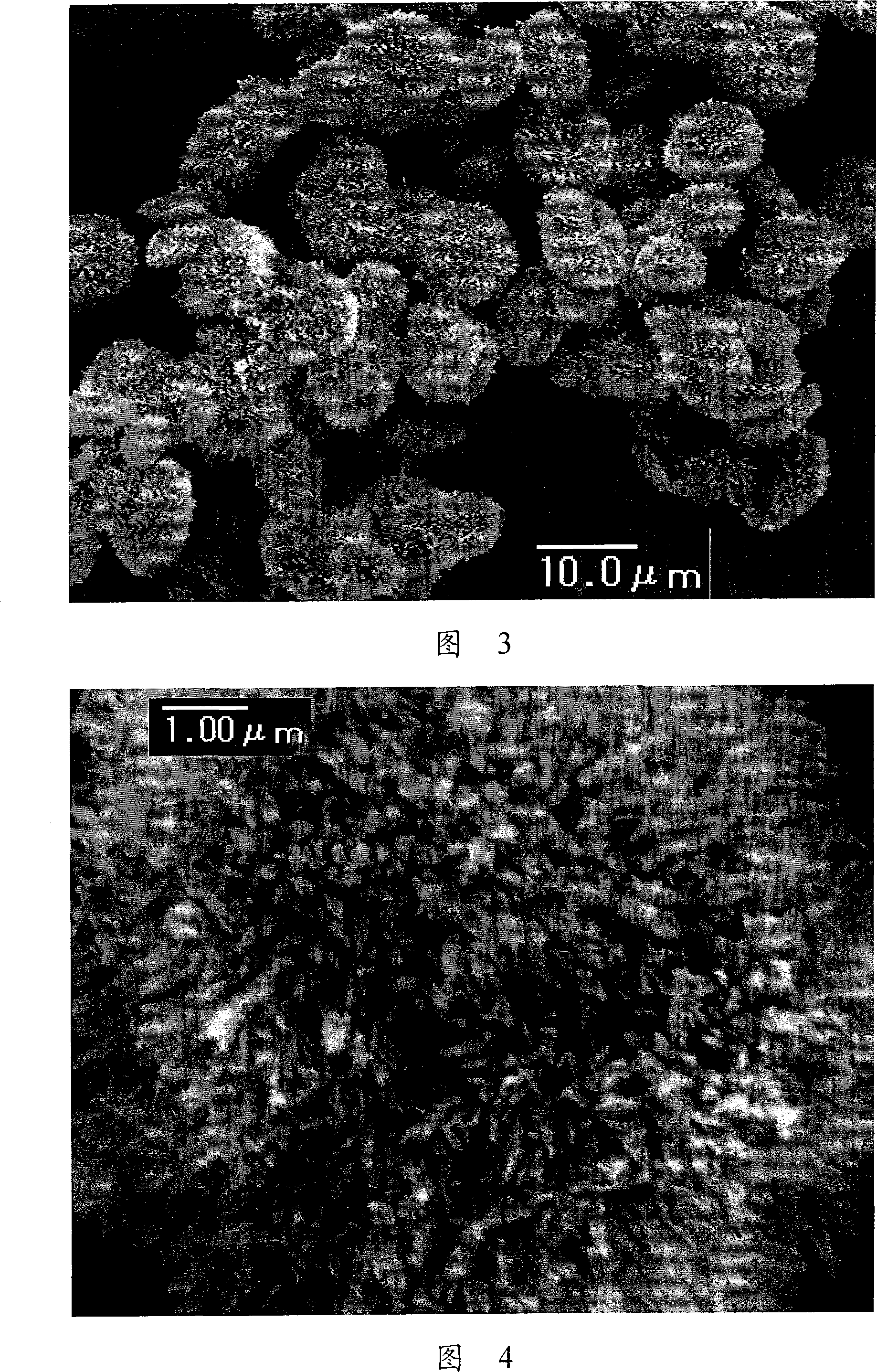

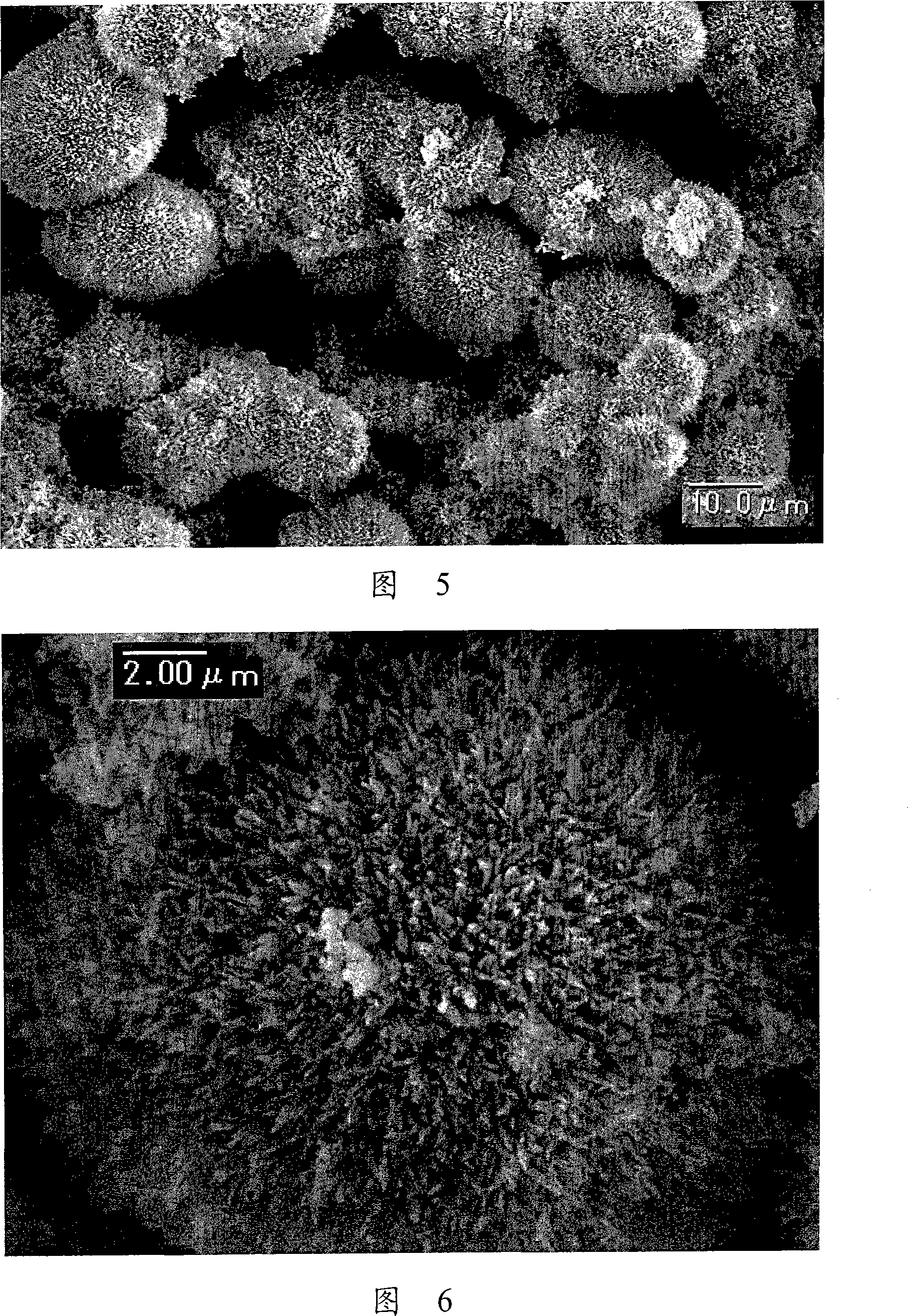

[0125] [Shape Analysis Using Scanning Electron Microscope]

[0126] The separated and dried sample was placed on a glass slide, and observed using a surface observation device VE-7800 produced by KEYENCE CORPORATION.

[0127] [Determination of metal content in silica by ICP]

[0128] Accurately weigh the separated and dried sample, and decompose it with a microwave sample decomposition device. Add ultra-pure water to the decomposition liquid, measure the amount of metal in the liquid with Optima 3300DV produced by Perkin Elmer, and calculate the metal content.

Synthetic example 1

[0130]

[0131] 3 g of commercially available linear polyethyloxazoline (number-average molecular weight 50,000, average degree of polymerization 5,000, manufactured by Aldrich) was dissolved in 15 mL of 5M aqueous hydrochloric acid. The solution was heated to 90° C. using an oil bath, and stirred at this temperature for 10 hours. Add 50ml of acetone to the reaction solution to completely precipitate the polymer, filter the precipitate, and wash with methanol three times to obtain white polyethyleneimine powder. use 1 H-NMR (heavy water) identifies the gained powder, confirms that the peak 1.2ppm (CH 3 ) and 2.3ppm (CH 2 )Completely disappear. That is, it was shown that polyethyloxazoline was completely hydrolyzed and converted into polyethyleneimine.

[0132] This powder was dissolved in 5 mL of distilled water, and 50 mL of 15% ammonia water was added dropwise to the solution while stirring. After the mixed solution was allowed to stand overnight, the precipitated pol...

Embodiment 1~5

[0134]

[0135] A certain amount of L-PEI powder obtained above was weighed and dispersed in distilled water to prepare a 1% L-PEI dispersion. The dispersion liquid was heated to 90° C. using an oil bath to obtain a completely transparent L-PEI aqueous solution. In the obtained L-PEI aqueous solution, add the metal ion species shown in Table 1 (embodiment 1: Cu(II) Nitrate; Example 2: Mn(II) nitrate; Example 3: Al(III) nitrate; Example 4: Eu(III) hydrochloride; Example 5: Zr(IV) nitrate) salt compound, and then, the solution was left at room temperature for 24 hours to obtain a L-PEI metal complex solution.

[0136] Add 1 mL of tetramethoxysilane (TMOS) and ethanol mixed solution (volume ratio 1 / 1) in the obtained PEI metal complex solution (1 mL), react at room temperature for 1 hour (TMOS is relative to the The usage ratio of ethylimine unit is 40 times equivalent). The generated solids were separated with a centrifugal separator, and the ethanol centrifugal separation pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com