Enzymatical method for synthesizing water-soluble ferulic acyl glyceride

A technology of feruloyl glyceride and feruloyl glycerol, which is applied in the field of enzymatic synthesis of water-soluble feruloyl glyceride, can solve the problems of long reaction time and low product yield, and achieve the effect of increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

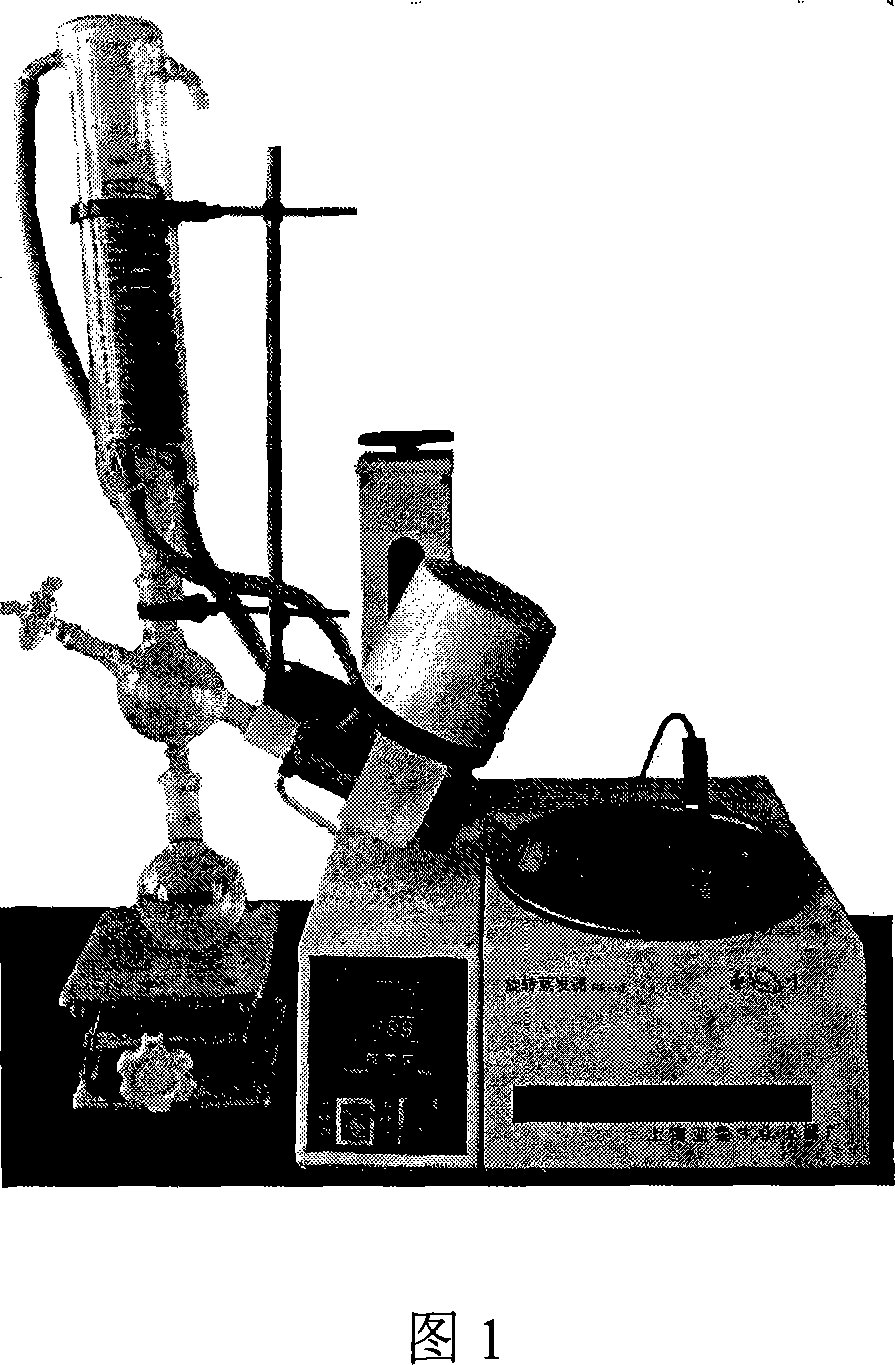

Image

Examples

Embodiment 1

[0035]The raw material quality indicators used are: ferulic acid (purity>99%), ethyl ferulate (purity>99%), glycerin (purity>99%), Novozym 435 (Denmark), Lipozyme RM IM (Denmark), LipozymeTL IM (Denmark), porcine pancreatic lipase (sigma).

[0036] (1) Screening of lipase, screening was performed from Novozym 435 (Denmark), Lipozyme RM IM (Denmark), Lipozyme TL IM (Denmark), and porcine pancreatic lipase (sigma). The results showed that Novozym435 (Candida antarctica lipase B) was the only lipase active on ethyl ferulic acid and feruloyl glyceride substrates. Therefore, we chose Novozym 435 as the lipase for the synthesis of feruloyl oleoyl glyceride.

[0037] (2) The establishment of the synthetic route, the esterification reaction of ferulic acid and glycerin, the transesterification reaction of ethyl ferulic acid and glycerol, the reactor is a water bath shaker, and all the other conditions are the same as above. As a result, the transesterification reaction route of ethy...

Embodiment 2

[0050] Feruloylglycerides were synthesized by transesterification of ethyl ferulate and glycerol in a vacuum rotary bioreactor under the action of Novozym 435 lipase;

[0051] The amount of enzyme added is 1% (w / w) based on the total substrate (total weight of ethyl ferulate and glycerol),

[0052] Substrate ratio: ethyl ferulate / glycerol (w / w) is 0.05:1,

[0053] Speed from 150rpm,

[0054] The reaction temperature was 80°C, and the reaction time was 10 hours.

[0055] The conversion rate of ethyl ferulic acid reaches 100% and the yield of feruloyl glyceride reaches more than 90%.

Embodiment 3

[0057] Feruloylglycerides were synthesized by transesterification of ethyl ferulate and glycerol in a vacuum rotary bioreactor under the action of Novozym 435 lipase;

[0058] The amount of enzyme added is 16% (w / w) based on total substrate (total weight of ethyl ferulate and glycerol),

[0059] Substrate ratio: ethyl ferulate / glycerol (w / w) is 0.5:1,

[0060] Speed from 50rpm,

[0061] The reaction temperature was 50°C, and the reaction time was 10 hours.

[0062] The conversion rate of ethyl ferulic acid reaches 100% and the yield of feruloyl glyceride reaches more than 90%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com