Flexible circuit board of LED illumination array

A flexible circuit board, LED lighting technology, applied in lighting device parts, lighting devices, lighting and heating equipment and other directions, can solve the problem of high flatness, smoothness and installation requirements, the negative impact of LED light source performance, and reduce LED light source. Service life and other issues, to achieve the effect of ensuring effective thermal contact area, improving application safety and stability, and reducing indirect heat dissipation links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

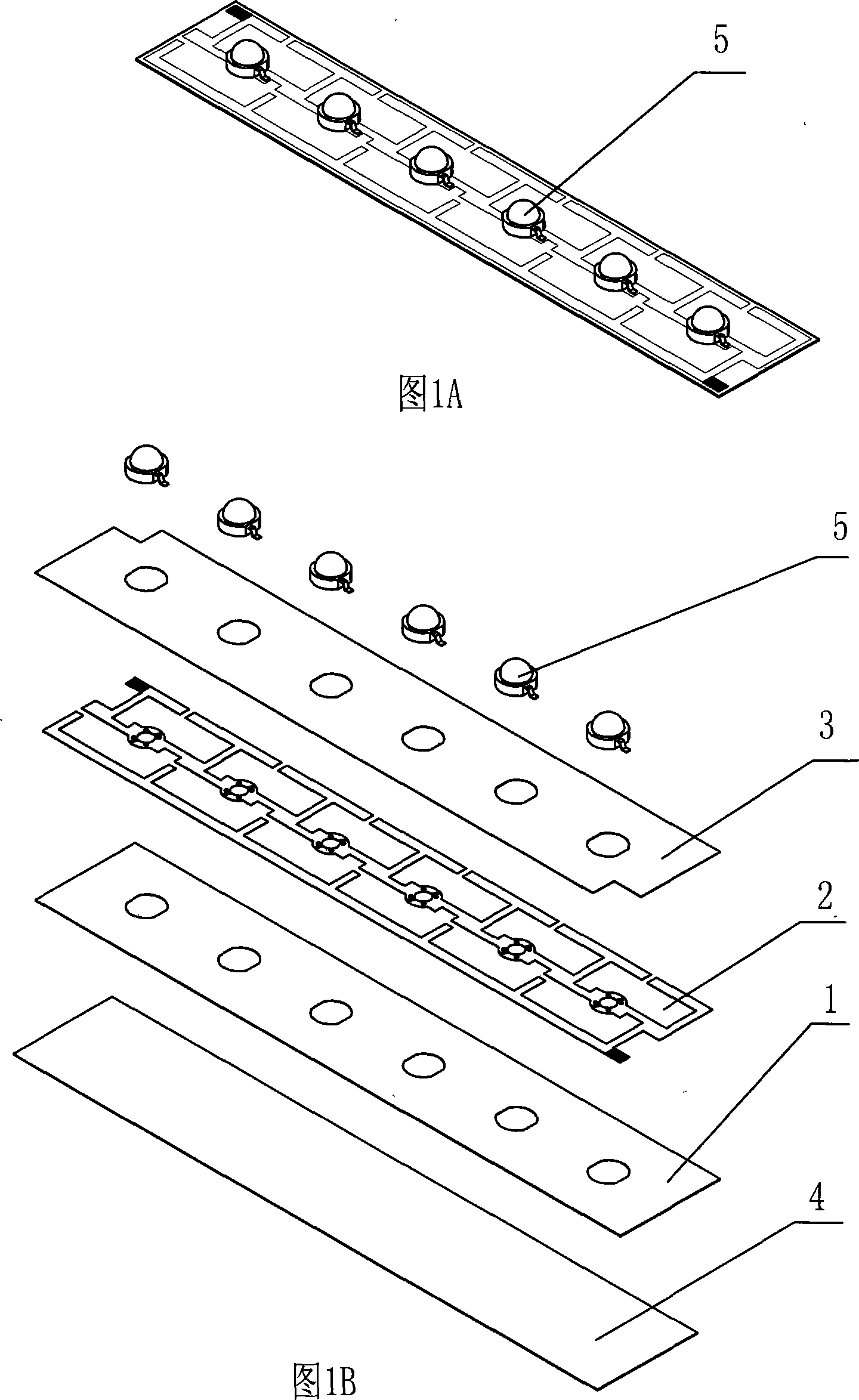

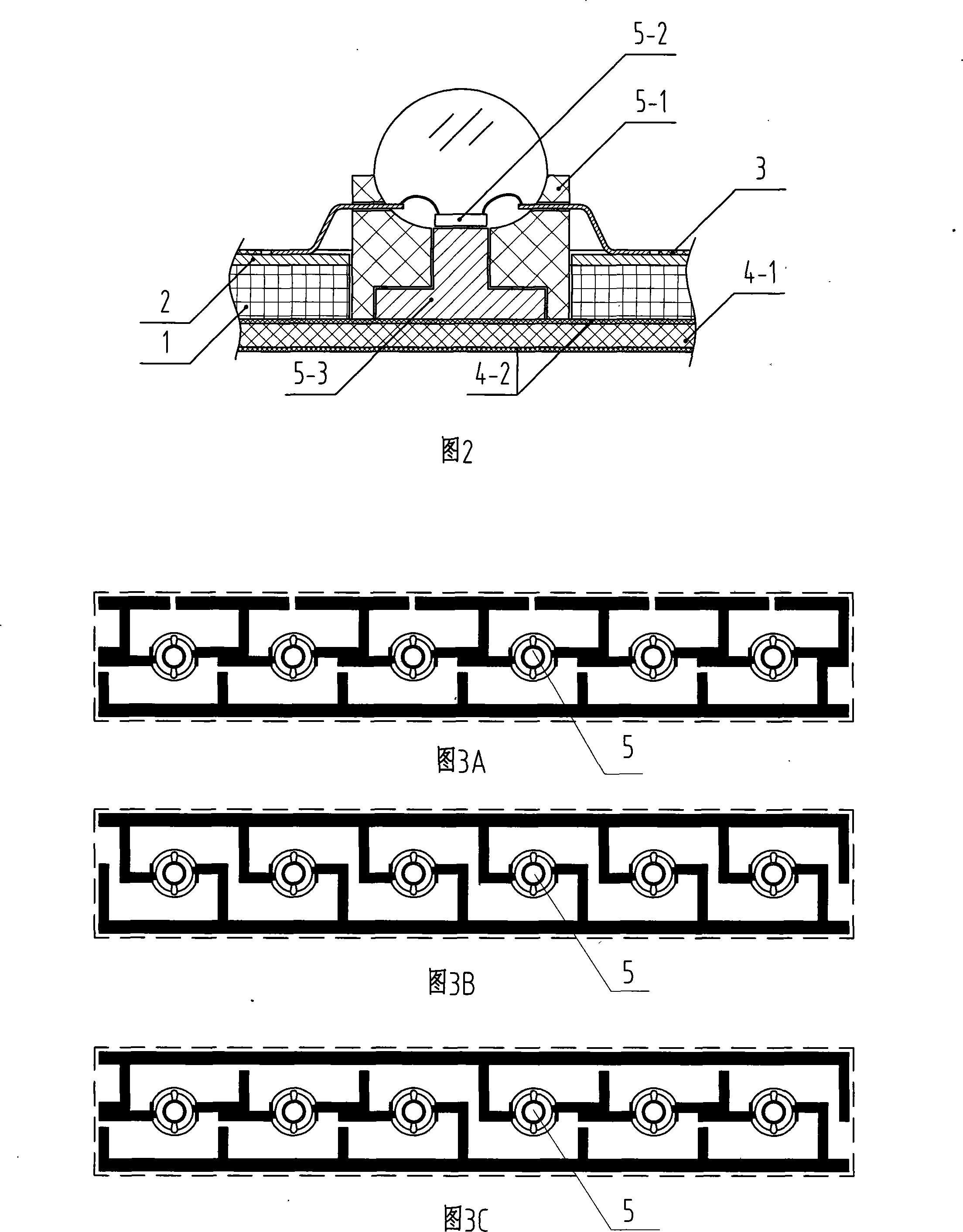

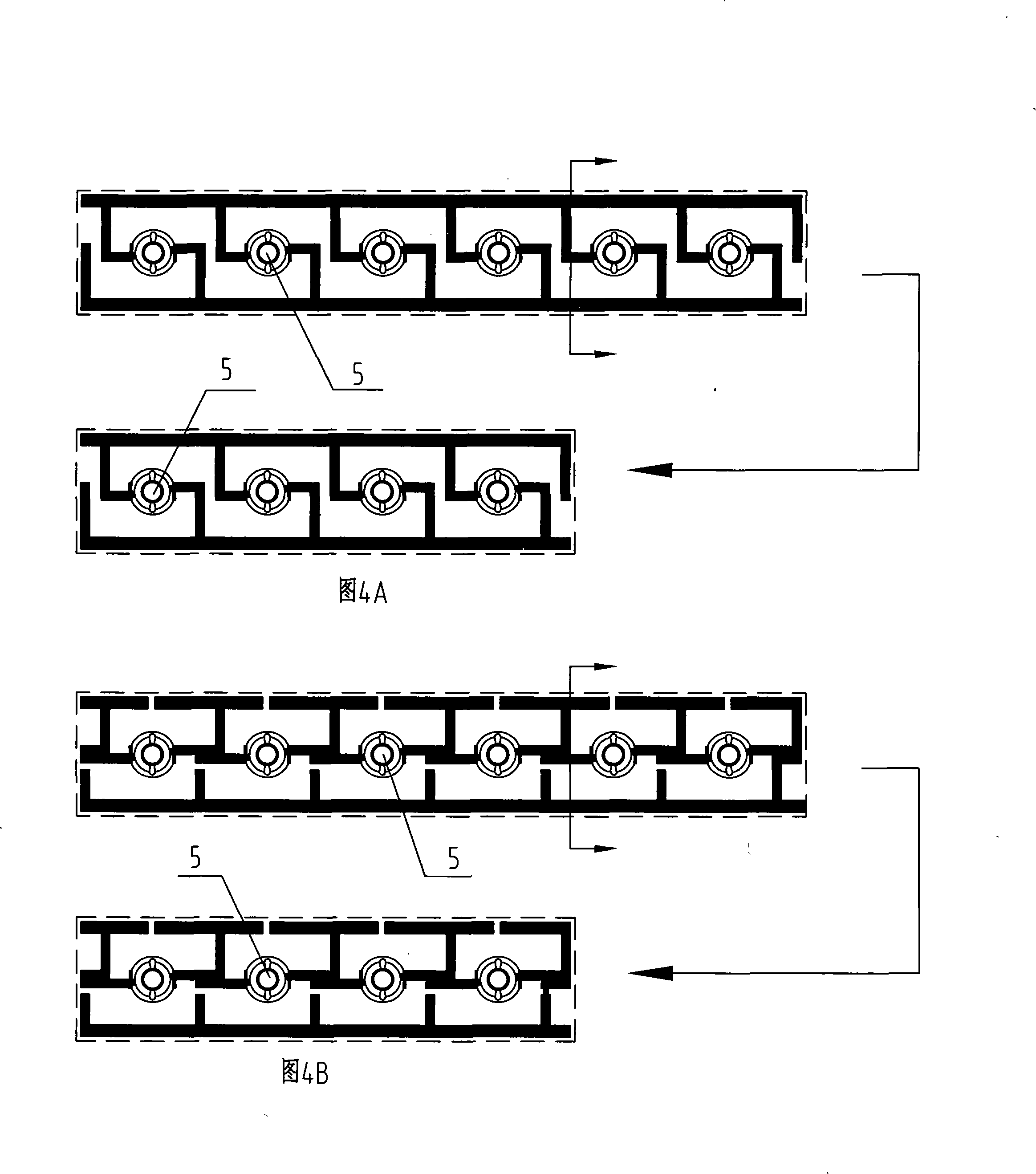

[0043] As shown in FIG. 5 , the LED lighting array flexible circuit board module is composed of a flexible substrate 1 , a connecting circuit 2 , an insulating coating layer 3 , a heat-conducting rubber pad 4 and an LED light source 5 . The flexible substrate 1 is bonded to the surface of the thermally conductive rubber pad 4 by the temperature-resistant strong adhesive layer 4-2 on one side of the thermally conductive rubber pad 4 , the connecting circuit 2 is placed on the surface of the flexible substrate 1 by thermocompression, and the transparent insulating coating layer 3 Cover the surface of the flexible substrate 1 and the connecting circuit 2 by spraying, and leave two pads at one end of the LED lighting array flexible circuit board module near the side. The pads are only electrically connected to the connecting circuit 2 without changing the original Wiring structure, pad surface gold-plated.

[0044] A single LED lighting array flexible circuit board module is insta...

Embodiment 2

[0048] As shown in FIG. 6 , each LED lighting array flexible circuit board module is composed of a flexible substrate 1 , a connecting circuit 2 , an insulating coating layer 3 , a heat-conducting rubber pad 4 and an LED light source 5 . The flexible substrate 1 is bonded to the surface of the thermally conductive rubber pad 4 by the temperature-resistant strong adhesive layer 4-2 on one side of the thermally conductive rubber pad 4 , the connecting circuit 2 is laid on the surface of the flexible substrate 1 by means of adhesive sheets, and the transparent insulating coating layer 3 Also cover the surface of the flexible substrate 1 and the connection circuit 2 with an adhesive sheet, and leave two pads at one end of the LED lighting array flexible circuit board module near the side. The pads are only electrically connected to the connection circuit 2 and are not connected. The original wiring structure is changed, and the surface of the pad is tinned, silver-plated, or gold-p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com