Production method of self-aligning contact hole

A technology of self-aligned contact holes and manufacturing methods, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of grid shoulders being cut off and the bottom of contact holes not being opened, so as to achieve good contour and engraving. The etching time is short and the effect of reducing the etching time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

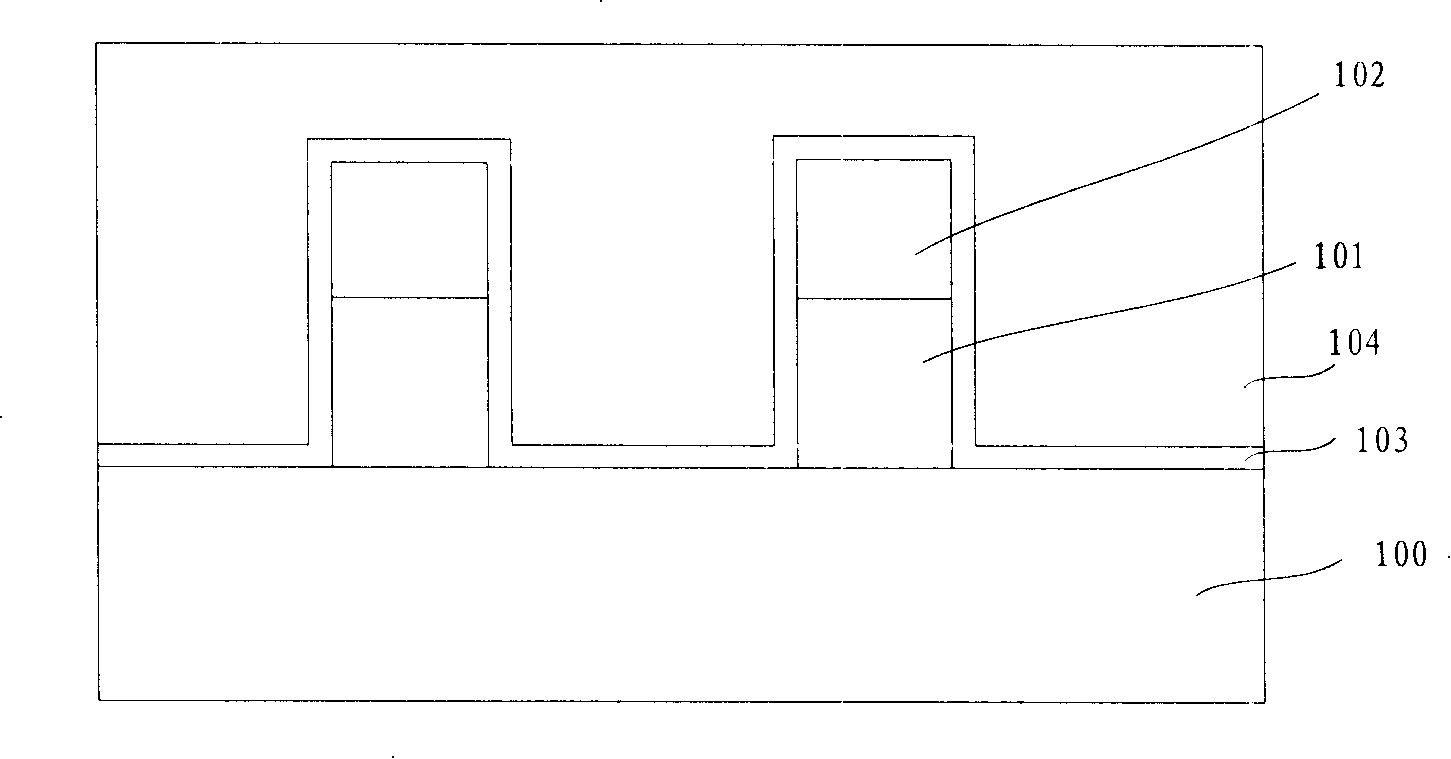

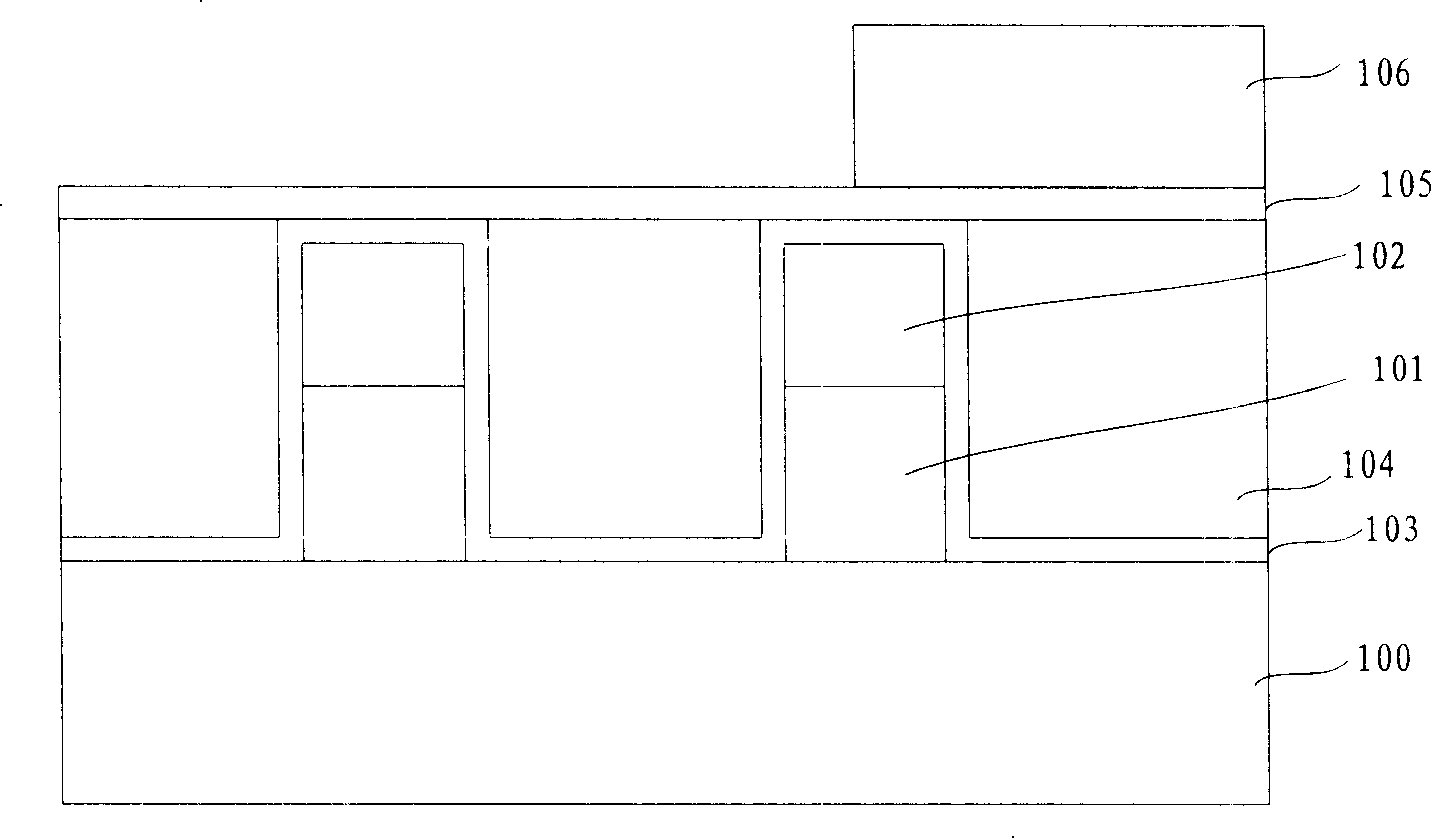

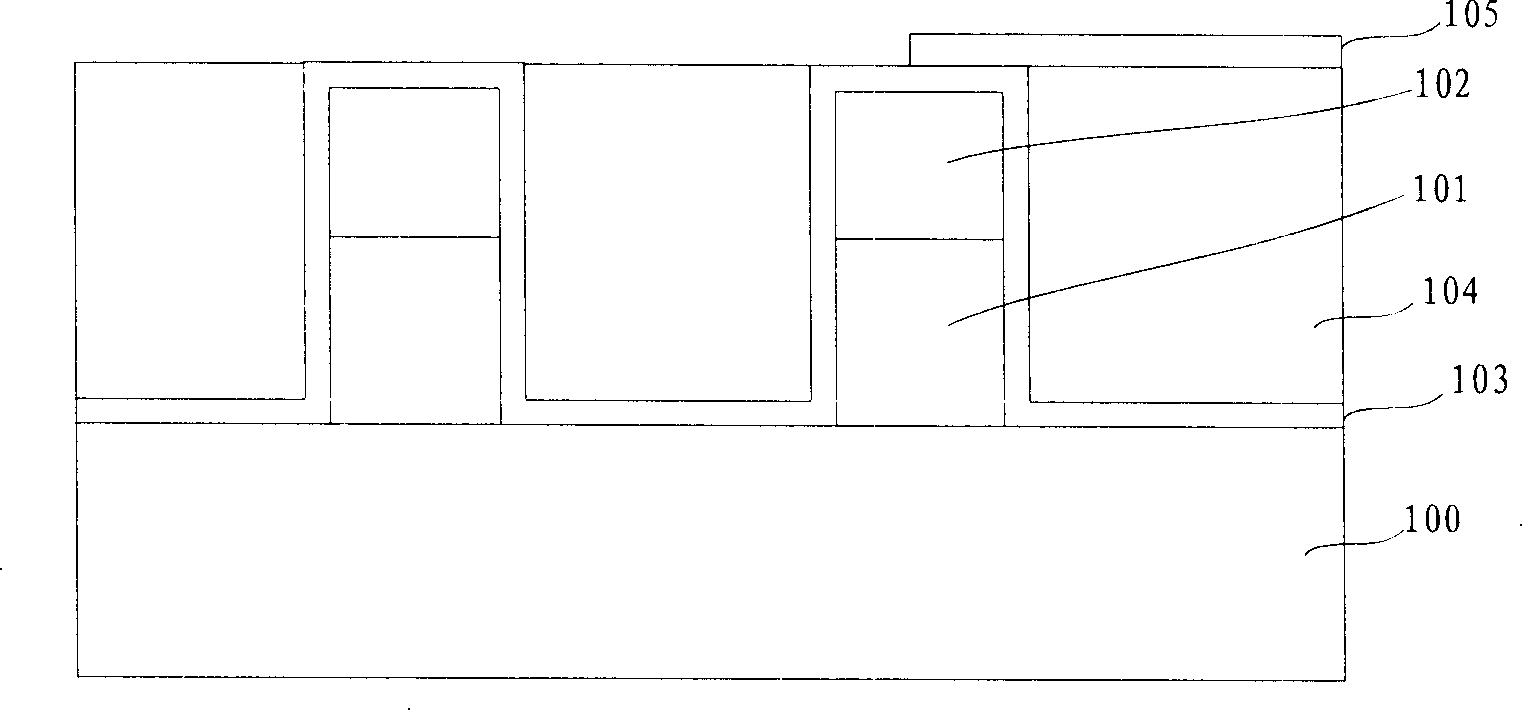

[0037] The method for manufacturing the self-aligned contact hole of the present invention firstly forms an etching barrier layer and a dielectric layer on a semiconductor substrate having at least two gate bumps, and then spin-coats a photoresist on the dielectric layer and forms a contact hole pattern , forming an opening in the dielectric layer by etching, the bottom of the opening is located between the two gates, and then cleaning the sidewall and bottom of the opening by wet method to remove the polymerization generated during etching material, and then remove the etching barrier layer on the sidewall and bottom of the opening by dry etching to form a contact hole. In the method of the present invention, the process of forming co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com