Preparation method of filling type sub-wavelength guide mode resonance optical filter

A technology of guided mode resonance and sub-wavelength gratings, which is applied in the direction of optical filters, optical mechanical equipment, and photolithography on patterned surfaces. It can solve the problems of difficult materials and difficult preparation of optical filters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

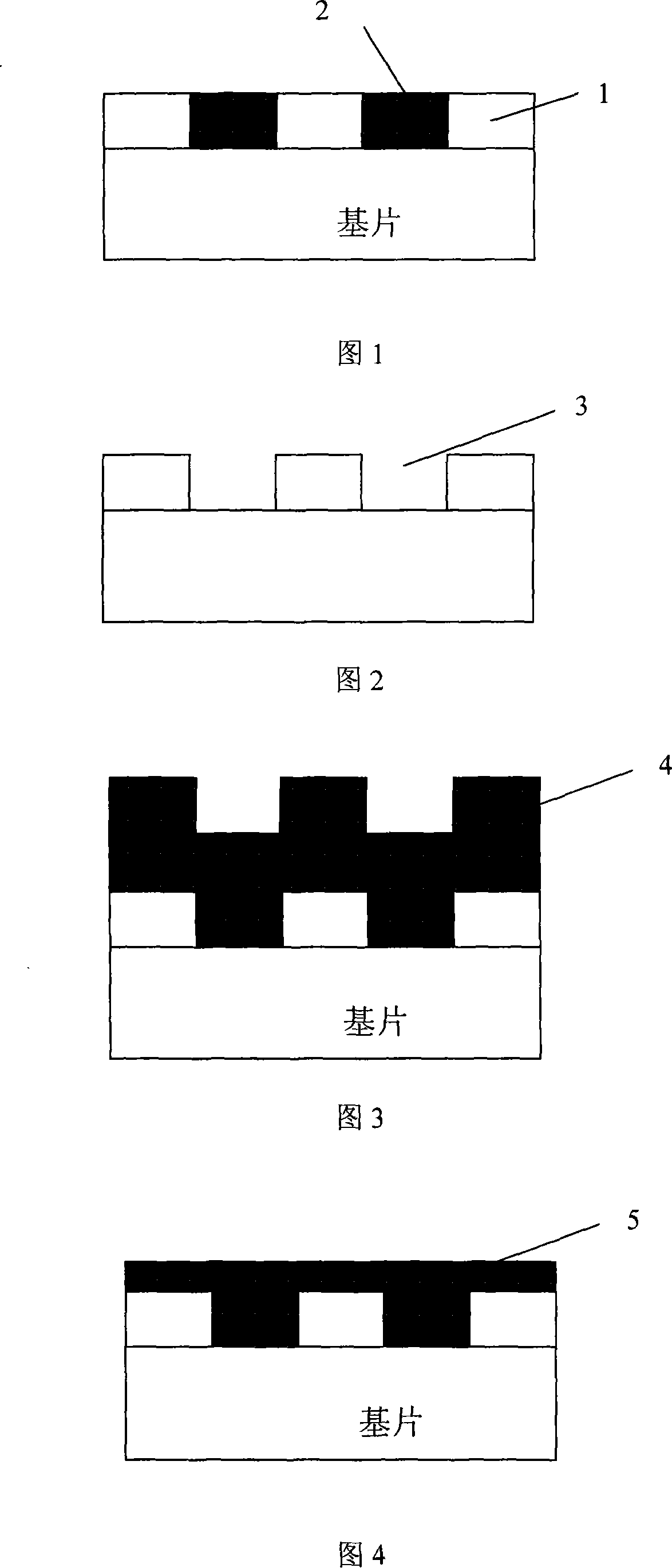

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0017] The purpose of this embodiment is to prepare a filled sub-wavelength guided mode resonant filter, which has a resonance effect on the 632.8nm TE wave incident at 57.88 degrees. The structure is shown in Figure 1. The specific parameters are: the grating period is 266nm, the duty ratio is 1:1, the groove 1 and the groove land 2 are made of quartz material and hafnium oxide material respectively, and the groove depth is 178nm. Specific steps are as follows:

[0018] (1) Make a mask on the quartz substrate by photolithography technology, transfer the mask structure to the quartz substrate by reactive ion beam etching technology, and prepare the initial air-filled subwavelength grating. Then use it as the substrate for coating and etching. The parameters of the grating structure obtained after transfer are: period 266nm, duty ratio 1:1, the groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com