Treatment method for increasing die self-demouding performance

A processing method and self-release technology, which is applied in the direction of manufacturing tools, coatings, casting molding equipment, etc., to achieve excellent wear resistance and corrosion resistance, reduce surface roughness, and improve the effect of mold self-release performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

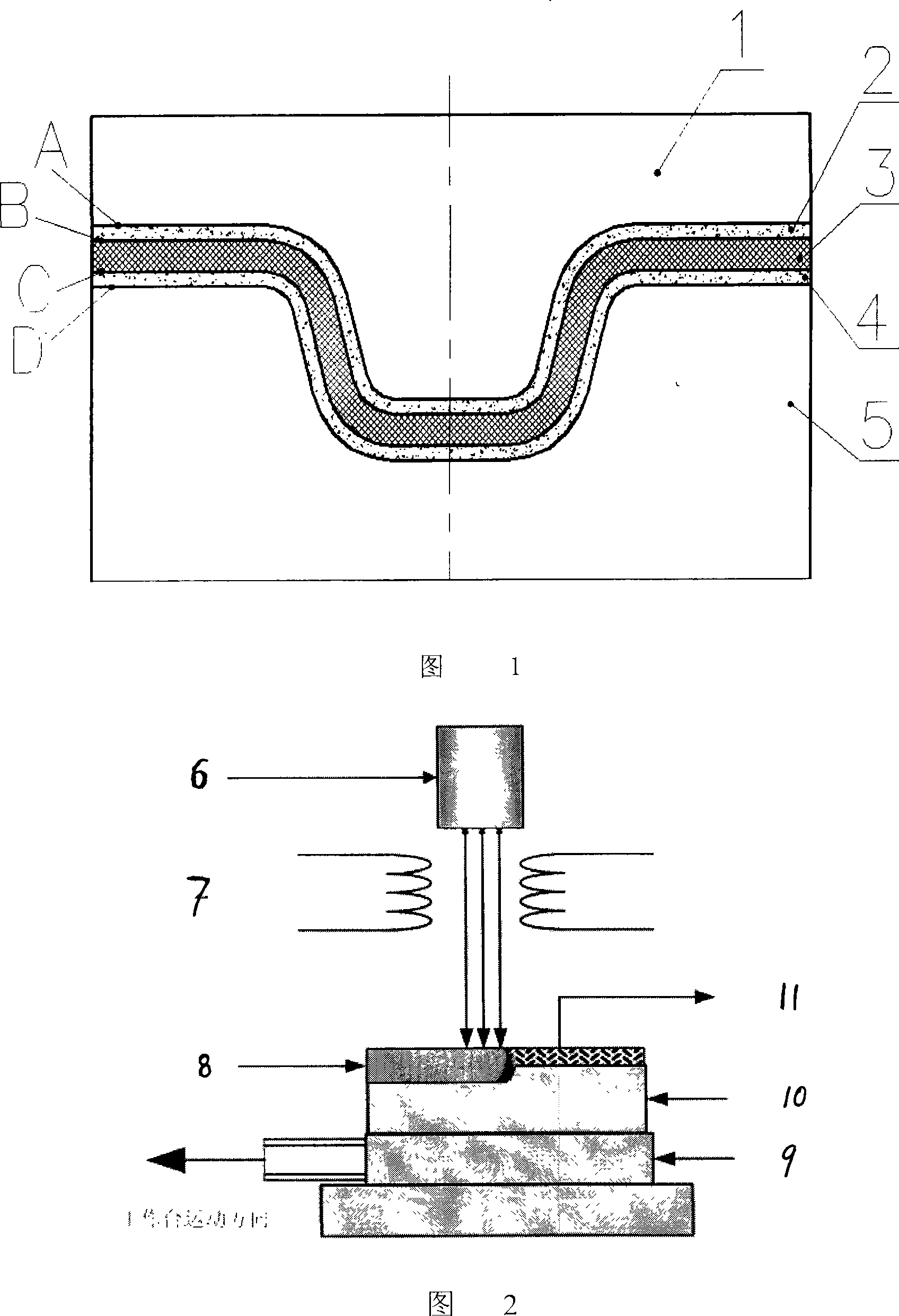

[0026] The process method for improving the self-demolding performance of the mold by electron beam processing in the present invention is based on the electron beam processing method, coating CrN+Cr composite alloy powder or TiN and other alloy powders on the forming surface of the mold, and strictly controlling the proportion and particle size of the alloy powder , coating thickness, energy density of the electron beam, number of irradiations, electron beam deflection mode, etc. to achieve.

[0027] In the method of the invention, one or more alloy powders are coated on the surface of the mould, and after the alloying of the mould's surface is realized by using a high-current pulsed electron beam, a layer of alloying protection layer-surface release layer is formed on the mould's forming surface. The specific method is as follows:

[0028] 1. Surface pretreatment: Pretreat the surface of the mold or the surface of the mold cavity to remove impurities including oil stains and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com