Carbon black conductive fluid

A technology of conductive liquid and carbon black, which is applied to printed circuits, electrical components, conductive materials dispersed in non-conductive inorganic materials, etc., can solve problems such as air pollution and poor adhesion of paint, and achieve less air pollution and better adhesion Good, the effect of stable dispersion system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

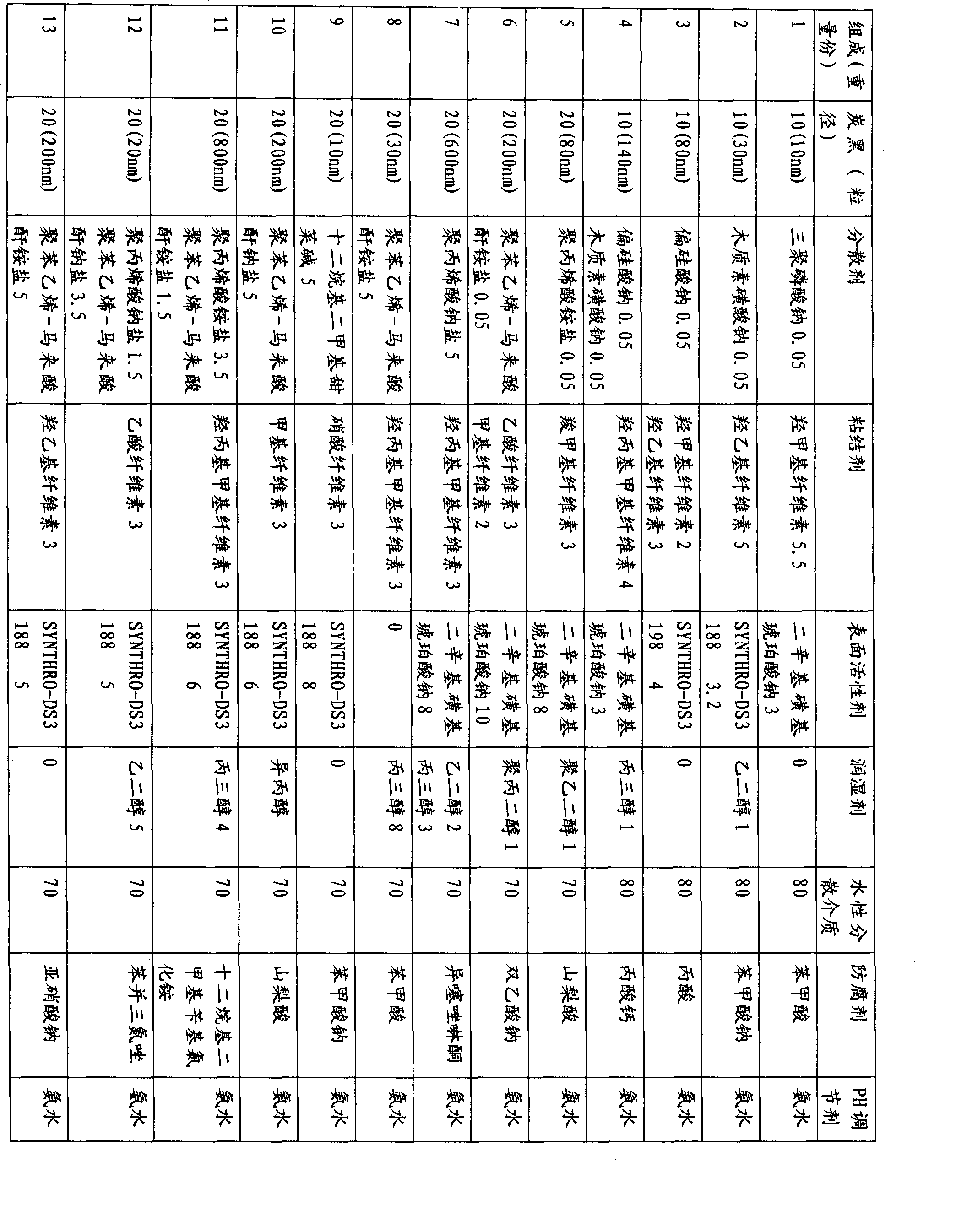

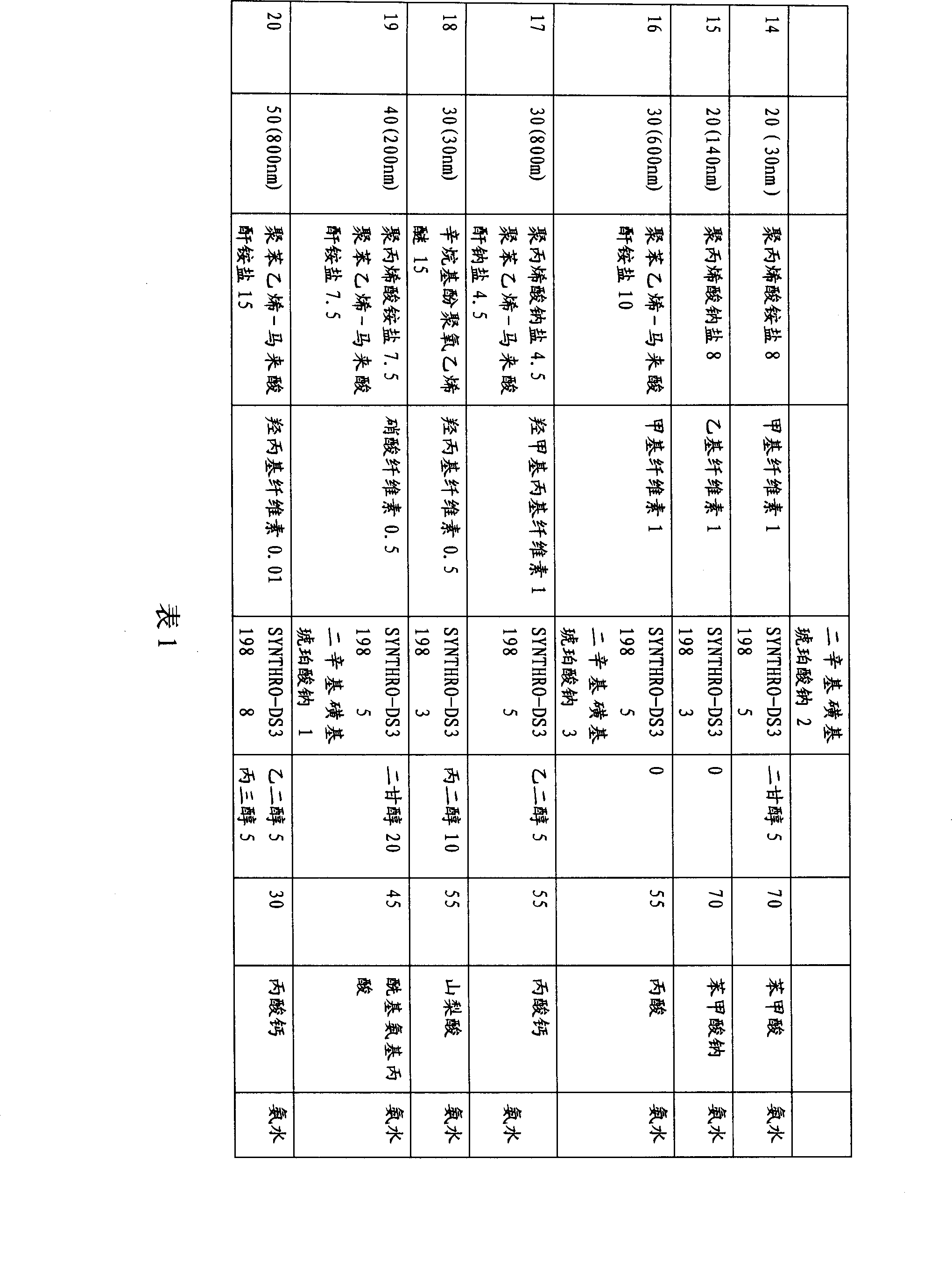

Image

Examples

Embodiment Construction

[0029] The anion dispersant of the present invention includes inorganic anion dispersant and organic anion dispersant, and inorganic anion dispersant can be polyphosphate, as sodium hexametaphosphate, sodium tripolyphosphate, sodium pyrophosphate etc.; Silicate such as Sodium metasilicate, etc.; lignosulfonate, such as sodium lignosulfonate, etc.; organic anion dispersants can be polycarboxylates such as polyacrylic acid and its derivatives, polymethacrylic acid and its derivatives; copolymers such as butyl Diene-styrene-acrylic acid copolymer and its derivatives, styrene-maleic anhydride copolymer and its derivatives, vinyl acetate-maleic anhydride copolymer and its derivatives; natural polymers and their modifications such as Gelatin, guar gum, ethyl cellulose, methyl cellulose, hydroxyethyl cellulose, hydroxypropyl cellulose, methyl propyl cellulose, etc.; polyester dispersants containing substituted amino end groups, poly(hydroxy Acid) ester dispersants, oligomeric soap di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com